Preparation method for zirconia ceramic rear cover of mobile phone

A zirconia ceramic and mobile phone back cover technology is applied in the field of preparation of high toughness zirconia ceramic mobile phone back cover, which can solve the problems of slow drying and degumming process, unsuitable for mass production, unsuitable for thin-walled parts molding, etc. Achieve the effect of reducing the amount of subsequent processing, meeting mass production, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

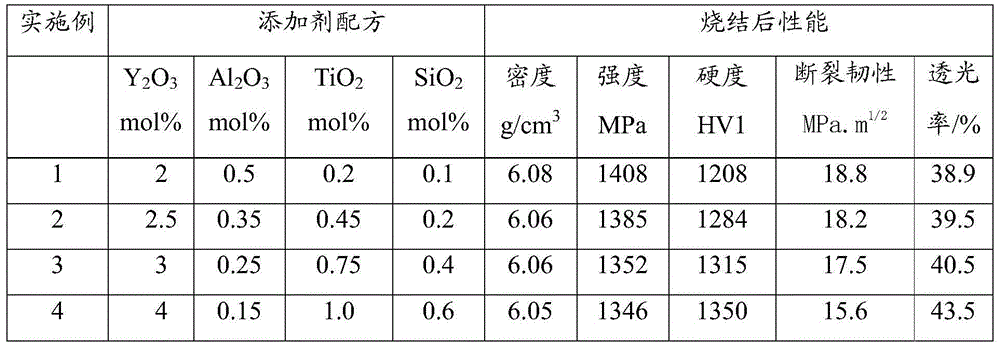

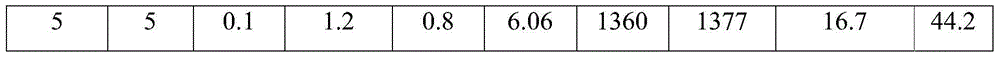

Examples

Embodiment 1

[0027] Embodiment 1: An embodiment of the preparation method of the zirconia ceramic mobile phone back cover of the present invention

[0028] A kind of embodiment of the preparation method of the zirconia ceramic mobile phone back cover of the present invention, described method comprises the following steps:

[0029] (1) Doping modification of nano-zirconia powder

[0030] Get 10kg of yttrium oxide-stabilized high-purity nano-zirconia powder, wherein the molar content of yttrium oxide is 2% of the nano-zirconia molar content in the yttria-stabilized high-purity nano-zirconia powder, and use deionized water to prepare For a suspension with a solid content of 60%, add 0.8wt% ammonium polyacrylate dispersant to the above suspension, add Al in the form of a soluble salt 2 o 3 、TiO 2 and SiO 2 , where the Al 2 o 3 The soluble salt of AlCl 3 ·6H 2 O, the Al 2 o 3 The molar content is 0.5% of the molar content of nano-zirconia in the yttria-stabilized high-purity nano-zirco...

Embodiment 2

[0037] Embodiment 2: An embodiment of the preparation method of the zirconia ceramic mobile phone back cover of the present invention

[0038] A kind of embodiment of the preparation method of the zirconia ceramic mobile phone back cover of the present invention, described method comprises the following steps:

[0039] (1) Doping modification of nano-zirconia powder

[0040] Get 10kg of yttrium oxide-stabilized high-purity nano-zirconia powder, wherein the molar content of yttrium oxide is 2.5% of the nano-zirconia molar content in the yttria-stabilized high-purity nano-zirconia powder, and prepare it with deionized water For a suspension with a solid content of 60%, add 0.5wt'% ammonium polyacrylate dispersant to the above suspension, add Al in the form of a soluble salt 2 o 3 、TiO 2 and SiO 2 , where the Al 2 o 3 The soluble salt of Al(NO) 3 9H 2 O, the Al 2 o 3 The molar content is 0.35% of the molar content of nano-zirconia in the yttria-stabilized high-purity na...

Embodiment 3

[0047] Embodiment 3: An embodiment of the preparation method of the zirconia ceramic mobile phone back cover of the present invention

[0048] A kind of embodiment of the preparation method of the zirconia ceramic mobile phone back cover of the present invention, described method comprises the following steps:

[0049] (1) Doping modification of nano-zirconia powder

[0050] Get 10kg of yttrium oxide-stabilized high-purity nano-zirconia powder, wherein the molar content of yttrium oxide is 3% of the nano-zirconia molar content in the yttria-stabilized high-purity nano-zirconia powder, and use deionized water to prepare For a suspension with a solid content of 40%, add 0.2wt% ammonium polyacrylate dispersant to the above suspension, add Al in the form of a soluble salt 2 o 3 、TiO 2 and SiO 2 , where the Al 2 o 3 The soluble salt of AlCl 3 ·6H 2 O, the Al 2 o 3 The molar content is 0.25% of the molar content of nano-zirconia in the yttria-stabilized high-purity nano-zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com