A water-soluble aggregate-asphalt interface antirust modifier and its preparation method and application

A water-soluble modifier technology, which is applied in the field of water-soluble aggregate-asphalt interface anti-rust modifier and preparation, can solve problems affecting road quality, adhesion indicators that cannot meet the specification requirements, and rust spots on the road surface. Achieve the effects of reducing the use of aggregates and transportation costs, inhibiting the rusting of the road surface, and enhancing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

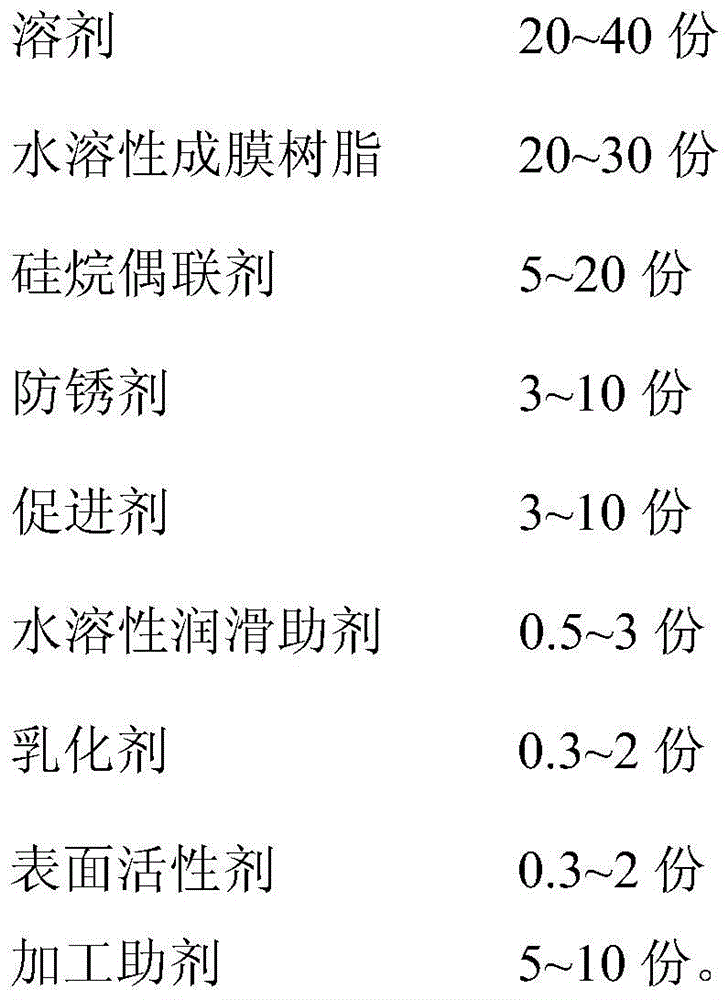

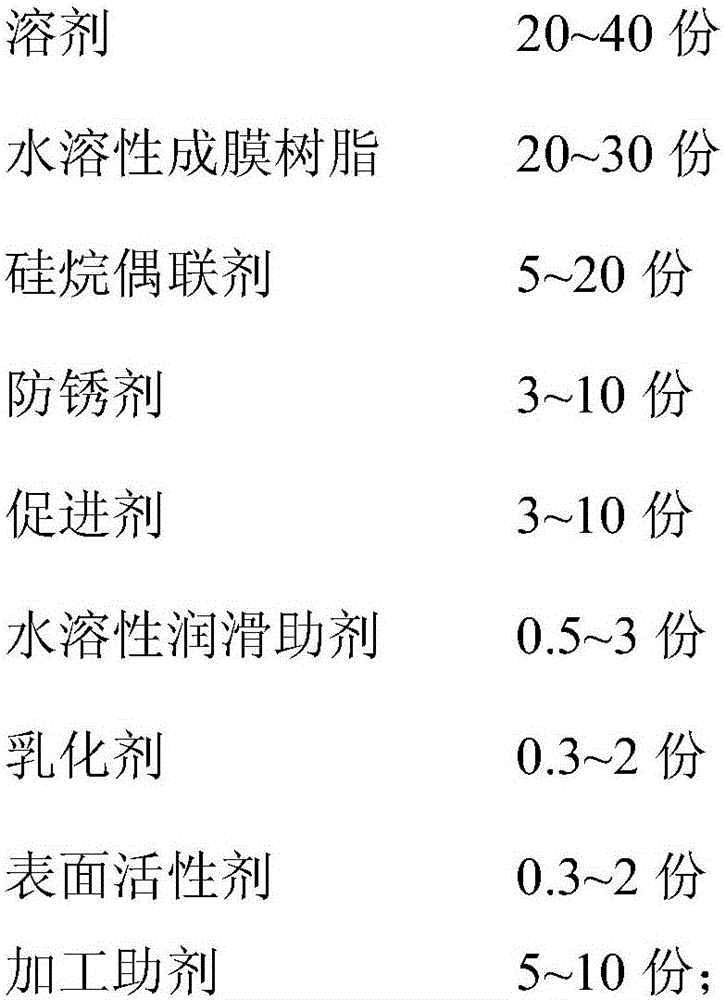

Method used

Image

Examples

Embodiment 1

[0031] (1) 15 parts of silane coupling agent γ-glycidyl etheroxypropyl trimethoxysilane (15g), 1 part of water-soluble lubricating aid (aqueous emulsion of dimethyl silicone oil), 0.5 parts of alkylbenzenesulfonate Sodium acid emulsifier and 25 parts of water-soluble epoxy film-forming resins are dissolved in 20 parts of deionized water, stirred and mixed evenly;

[0032] (2) 8 parts of p-chlorobenzoic acid promotors, 6.5 parts of aminoethylpiperazine, 7 parts of rust inhibitors (by weight ratio being 0.5:1 anhydrous sodium silicate and particle diameter are nanometer dioxide of 90nm Silicon powder) and 1 part of amino acid surfactant were dissolved in 16 parts of deionized water, stirred and mixed evenly.

[0033] (3) Mix the solutions obtained in step (1) and step (2), and stir and mix evenly at room temperature to obtain a water-soluble aggregate-asphalt interface rust-proof modifier.

[0034] The application of the water-soluble aggregate-asphalt interface antirust modifi...

Embodiment 2

[0043] (1) Mix 18 parts of silane coupling agent γ-glycidyl etheroxypropylmethyl dimethoxysilane (18g), 1.5 parts of water-soluble lubricating aid (aqueous emulsion of dimethyl silicone oil), 2 parts of alkane Dissolve sodium phenylbenzenesulfonate emulsifier and 20 parts of water-soluble epoxy film-forming resin in 20 parts of deionized water, stir and mix evenly;

[0044] (2) 8 parts of triethanolamine accelerators, 7 parts of aminoethylpiperazine, 8.5 parts of rust inhibitors (by weight ratio being 0.4:1 anhydrous sodium silicate and particle diameter are composed of nano-silica sol of 5nm ) and 1.5 parts of betaine-type surfactants were dissolved in 15 parts of deionized water, stirred and mixed evenly.

[0045] (3) Mix the solutions obtained in step (1) and step (2), and stir and mix evenly at room temperature to obtain a water-soluble aggregate-asphalt interface rust-proof modifier.

[0046] The application of the water-soluble aggregate-asphalt interface antirust modif...

Embodiment 3

[0050] (1) 5 parts of silane coupling agent γ-glycidyl ether oxypropyl methyl dimethoxysilane (5g), 0.5 part of water-soluble lubricating aid (polyether modified polysiloxane), 0.3 Part of gum arabic emulsifier and 30 parts of water-soluble acrylic film-forming resin are dissolved in 10 parts of alcohol, stirred and mixed evenly;

[0051] (2) 3 parts of tin protochloride promotor, 10 parts of diethylenetriamine, 3 parts of antirust agents (by weight ratio being 6:1 sodium silicate pentahydrate and particle diameter are the nano silica powder of 50nm Composition) and 0.3 parts of betaine-type surfactants were dissolved in 10 parts of alcohol, stirred and mixed evenly.

[0052] (3) Mix the solutions obtained in step (1) and step (2), and stir and mix evenly at room temperature to obtain a water-soluble aggregate-asphalt interface rust-proof modifier.

[0053] The application of the water-soluble aggregate-asphalt interface antirust modifier of this embodiment in the surface mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com