A kind of low-carbon and low-silicon vertical downward electrode and preparation method thereof

A low-carbon, low-silicon, vertical-down technology, applied in the direction of welding equipment, welding medium, manufacturing tools, etc., can solve the problems of not meeting the requirements of corrosion-resistant steel, not suitable for galvanized pot welding, and the existence of welding cracks, etc., to achieve good Resistance to molten zinc corrosion, improved welding efficiency, and stable arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

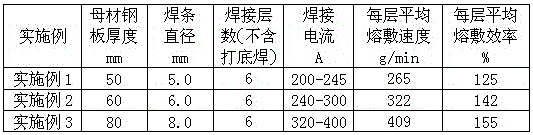

Examples

Embodiment 1

[0017] The coating (mass fraction) used is: microcrystalline cellulose: 25%, wood flour: 8%, hydroxymethyl cellulose: 8%, ilmenite: 18%, marble: 9%, low-carbon ferromanganese: 8%, ferro-titanium: 3.5%, aluminum powder: 4.5%, dolomite: 10%; Cr 2 O 3 : 3%, ZrO 2 : 3%.

[0018] The chemical composition (mass fraction) of the electrode steel is C: 0.02%, Si: 0.02%, Mn: 0.40%, P: 0.008%, S: 0.0008%, Alt: 0.035%, the rest is Fe and unavoidable impurities.

[0019] Preparation method: First, draw the special welding rod steel into a welding core, then mix the above coating components evenly, add sodium-potassium mixed water glass, stir and evenly press coating on the surface of the special welding core to make a diameter of 2.0-8.0mm, Electrodes with a length of 250-450mm are dried at room temperature and then dried at 220°C for 2 hours.

Embodiment 2

[0021] The formula (mass fraction) used for the coating is: microcrystalline cellulose: 20%, wood flour: 10%, hydroxymethyl cellulose: 10%, ilmenite: 20%, marble: 8%, low-carbon ferromanganese : 8%, ferro-titanium: 3%, aluminum powder: 3%, dolomite: 10%, Cr 2 O 3 : 3%, ZrO 2 :5%.

[0022] The chemical composition (mass fraction) of the electrode steel is C: 0.01%, Si: 0.01%, Mn: 0.60%, P: 0.007%, S: 0.0003%, Alt: 0.038%, and the rest is Fe and unavoidable impurities.

[0023] The preparation method is the same as in Example 1.

Embodiment 3

[0025] The coating formula (mass fraction) used is: microcrystalline cellulose: 22%, wood flour: 11%, hydroxymethyl cellulose: 9%, ilmenite: 16%, marble: 8%, low-carbon ferromanganese : 7%, ferro-titanium: 5%, aluminum powder: 3%, dolomite: 12%, Cr 2 O 3 : 3%, ZrO 2 : 4%.

[0026] The chemical composition (mass fraction) of the electrode steel is: C: 0.01%, Si: 0.01%, Mn: 0.55%, P: 0.005%, S: 0.001%, Alt: 0.035%, the rest is Fe and unavoidable impurities .

[0027] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com