High-toughness and high-hardness die steel and preparation method thereof

A high-hardness, high-toughness technology, applied in the field of die steel manufacturing, can solve the problem that the performance of die steel is difficult to meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

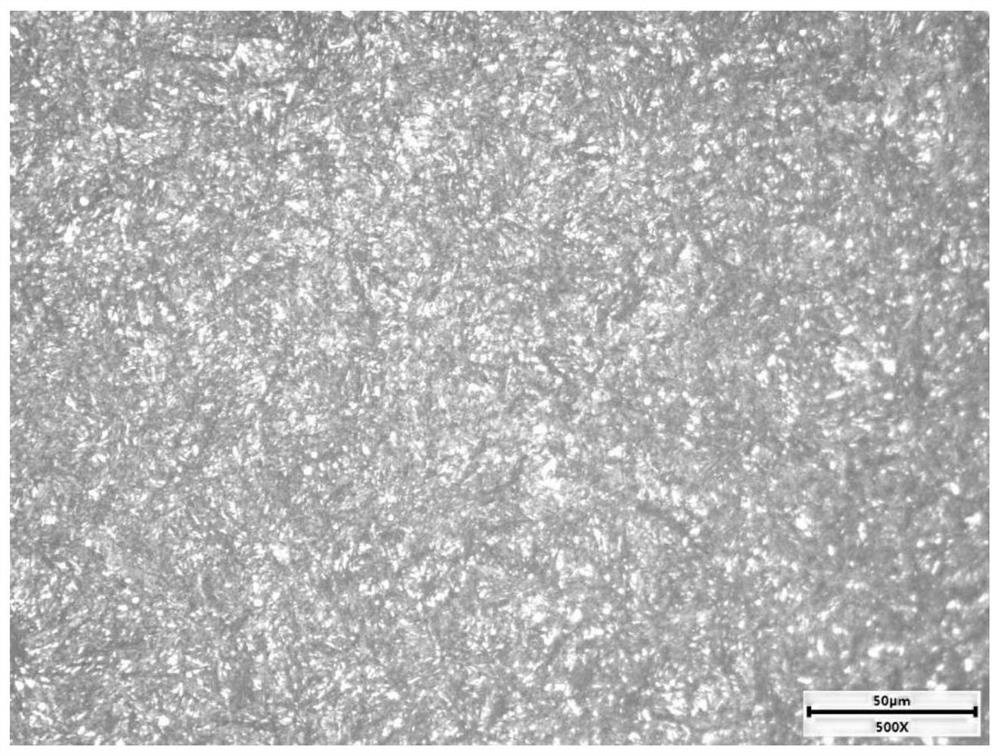

Image

Examples

preparation example Construction

[0035]The present invention also provides a method for preparing the high-toughness and high-hardness mold steel described in the above technical solution, comprising the following steps:

[0036] (1) smelting after mixing alloy raw materials to obtain steel ingots;

[0037] (2) forging the steel ingot obtained in the step (1) to obtain a forged alloy;

[0038] (3) heat-treating the wrought alloy obtained in the step (2) to obtain a mold steel with high toughness and high hardness.

[0039] In the invention, alloy raw materials are mixed and smelted to obtain steel ingots. In the present invention, there is no special limitation on the type and source of the alloy raw materials, and the raw materials known to those skilled in the art that can provide the above alloy elements can be used. In the present invention, there is no special limitation on the operation of mixing the alloy raw materials, and the technical solutions for preparing the mixed materials well known to those...

Embodiment 1

[0055] In terms of mass percentage, the composition of the high toughness and high hardness die steel is: C: 0.78%, Si: 0.3%, Mn: 0.5%, Cr: 5.1%, Mo: 2.4%, V: 0.55%, P<0.02 %, S<0.001% and the balance of Fe;

[0056] The preparation method of the high toughness and high hardness die steel is:

[0057] (1) Carry out the electric furnace smelting after batching is mixed according to the above-mentioned weight percentage, control tapping P0.018wt%, then pass through LF furnace refining, control S 0.004wt%; carry out degassing through VD furnace again, control the oxygen content in the steel 0.0025wt% , the H content is 0.0002wt%; pouring is then carried out under the protection of argon; and then through the atmosphere protection electroslag remelting, the oxygen content is reduced to 0.002wt%, the sulfur content is reduced to 0.0008wt%, and the steel ingot is obtained;

[0058] (2) Forging the steel ingot obtained in the step (1), first forging the blank, the heating temperatur...

Embodiment 2

[0061] In terms of mass percentage, the composition of the high toughness and high hardness die steel is: C: 0.75%, Si: 0.25%, Mn: 0.55%, Cr: 5.15%, Mo: 2.45%, V: 0.50%, P<0.02 %, S<0.002% and the balance of Fe;

[0062] The preparation method of the high toughness and high hardness die steel is:

[0063] (1) According to the above-mentioned weight percentage, carry out electric furnace smelting after batching and mixing, control tapping P0.017wt%, then refine through LF furnace, control S 0.0045wt%; carry out degassing through VD furnace again, control oxygen content in steel 0.0025wt% , the H content is 0.00012wt%; pouring is then carried out under the protection of argon; and then through the electroslag remelting under the protection of the atmosphere, the oxygen and sulfur contents are all reduced to 0.001wt%, and the steel ingot is obtained;

[0064] (2) Forging the steel ingot obtained in the step (1), first forging the blank, the heating temperature of the forging bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com