Gamma radiation protective clothing preparing method

A technology of gamma radiation and protective clothing, which is applied in the field of preparation of gamma radiation protective clothing, can solve the problems that the safety, softness and comfort cannot reach radiation protective clothing, cannot achieve effective radiation protection, and the content of shielding substances is low. Achieve the effect of improving compatibility and mixing uniformity, improving production conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

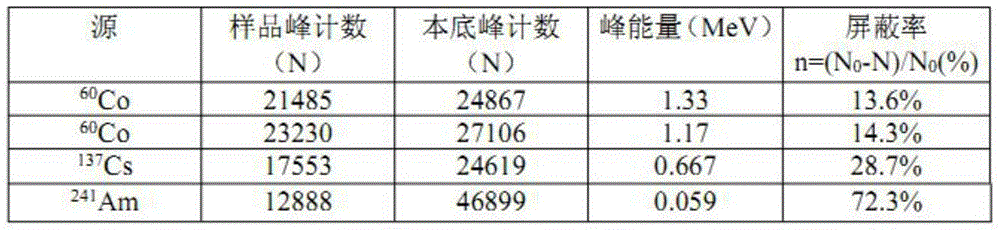

Examples

example 1

[0023] Using lead tungstate (PbWO4) as the radiation protection powder, the micro-nano-level modified filler was prepared by ball milling, and the EPDM rubber was used as the polymer matrix, and the powder and rubber were well compounded by mixing; secondly , using resorcinol, formaldehyde and latex three-component caustic alkali emulsion as a binder to impregnate the fiber fabric; finally, the rubber-fiber fabric is obtained by calendering, and then vulcanized to make protective rubber clothing. The specific steps are as follows:

[0024] Add 0.025g of silane coupling agent KH570 to the mixed solution of 10ml of distilled water and 13ml of absolute ethanol, stir for 30 minutes to fully hydrolyze KH570, then put the mixed liquid, 10g of lead tungstate powder, and 100g of zirconia beads in tetrafluoroethylene In an ethylene ball mill jar, ball mill at a speed of 300r / min for 8 hours to obtain the lead tungstate viscous liquid modified by KH570. The liquid and zirconium beads a...

example 2

[0036] Using lead oxide (Pb3O4) and bismuth oxide (Bi2O3) as radiation protection powder, it is modified by ball milling by adding modifier cetyltrimethylammonium bromide (CTAB), and after being filtered and dried, it is mixed with silicone rubber at 75 Mix evenly at ℃; secondly, use G-988 silicone adhesive to coat the non-woven fabric three times to increase the bonding strength; finally, obtain the silicone rubber-non-woven fabric by calendering, and vulcanize at room temperature Silicone rubber protective clothing. The specific steps are as follows:

[0037]Add 0.02g of cetyltrimethylammonium bromide to a mixed solution containing 10ml of distilled water and 13ml of absolute ethanol, then put the mixed liquid, 10g of lead oxide powder, and 100g of zirconia beads into a tetrafluoroethylene ball mill jar , and ball milled at 500r / min for 16 hours, filtered, centrifuged, and vacuum-dried at 80°C to obtain lead oxide powder with an average particle size of 0.1 μm to 1 μm. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com