Preparation process for highly oriented graphite composite material

A composite material and preparation technology, which is applied in the field of high-oriented graphite composite material preparation technology, can solve the problems of reducing graphite strength, difficulty in reaching sintering temperature, and low compactness, so as to improve oxidation resistance, reduce sintering temperature, and improve compactness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

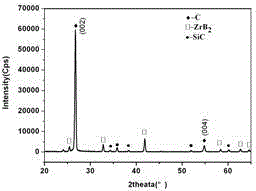

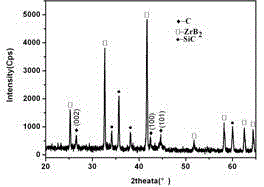

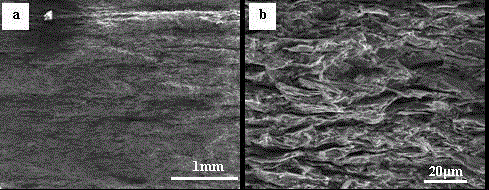

[0030] 1. Preparation of graphite casting sheet: first weigh 29.32 grams of polyvinyl butyral, 29.32 grams of polyvinyl alcohol, and 586.4 grams of ethanol, stir well, then add 154 grams of sheets with a diameter of 5-20 μm and a thickness of 1-2 μm Shaped graphite, 91.2 grams of zirconium boride powder of 1 to 5 μm and 48 grams of silicon carbide powder of 0.5 to 2 μm are stirred evenly to form zirconium boride cast material, in which flake graphite powder, zirconium boride powder and silicon carbide powder are Weigh according to 70%: 15%: 15% volume percentage; then tape casting, drying at room temperature and demoulding to obtain a graphite casting sheet with a thickness of 50-150 μm;

[0031] 2) Slice the cast graphite sheet according to the size of the mold;

[0032] 3) Superimpose the sliced graphite casting sheet into the graphite abrasive tool, pre-press molding, the molding pressure is 20MPa, and the temperature is 80°C;

[0033] 4) Put the pre-pressed green body t...

Embodiment 2

[0036] 1. Preparation of graphite casting sheet: first weigh 73.32 grams of polyvinyl butyral, 73.32 grams of polyethylene glycol, and 1466.4 grams of ethanol, stir well, then add 198 grams of graphite with a diameter of 5-20 μm and a thickness of 1-2 μm Flake graphite, 30.4 grams of zirconium boride powder of 1-5 μm and 16 grams of silicon carbide powder of 0.5-2 μm, stir evenly to form zirconium boride cast material, of which flake graphite powder, zirconium boride powder and silicon carbide powder It is weighed according to 90%: 5%: 5% volume percentage; then tape casting, drying at room temperature and demoulding to obtain a graphite casting sheet with a thickness of 50-150 μm;

[0037] 2) Slice the cast graphite sheet according to the size of the mold;

[0038] 3) Superimpose the sliced graphite cast sheets into the graphite abrasive tool, and pre-press molding, the molding pressure is 40MPa, and the temperature is 100°C;

[0039] 4) Put the pre-pressed green body toge...

Embodiment 3

[0043]1. Preparation of graphite casting sheet: first weigh 51.88 grams of polyvinyl butyral, 21.88 grams of polyvinyl alcohol, 30 grams of polyethylene glycol, and 1037.6 grams of ethanol, stir well, then add 165 grams of 5-20 μm in diameter, Flake graphite with a thickness of 1-2 μm, 30.4 grams of zirconium boride powder of 1-5 μm and 64 grams of silicon carbide powder of 0.5-2 μm are stirred evenly to form a zirconium boride casting material, in which flake graphite powder, boride Zirconium powder and silicon carbide powder are weighed according to 75%: 5%: 20% volume percentage; then tape casting, drying at room temperature and demoulding to obtain a graphite casting sheet with a thickness of 50-150 μm;

[0044] 2) Slice the cast graphite sheet according to the size of the mold;

[0045] 3) Superimpose the sliced graphite cast sheets into the graphite abrasive tool, pre-press molding, the molding pressure is 30MPa, and the temperature is 90°C;

[0046] 4) Put the pre-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com