Method for preparing electrode material molybdate for super capacitor and application thereof

A technology for supercapacitors and electrode materials, applied in the direction of hybrid capacitor electrodes, etc., can solve problems that have not yet been discovered, and achieve the effects of simple synthesis process, excellent supercapacitor performance, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

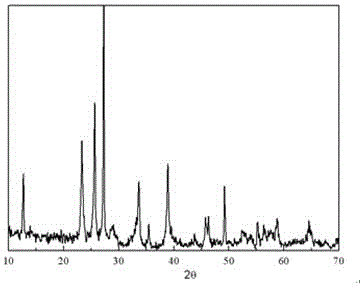

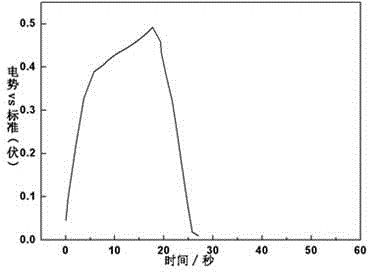

Image

Examples

Embodiment 1

[0021] Dissolve cobalt acetate and sodium molybdate in a solution composed of water and oleylamine at a molar ratio of 1:1.5, the molar concentration of cobalt acetate is 0.05 mol / L, and the molar concentration of sodium molybdate is 0.075 mol / L. The volume of amine accounts for 2% of the solution composed of water and oleylamine. After fully stirring and dissolving, it is transferred to the reaction kettle, 160 o C hydrothermal reaction for 18 h. After the thermal reaction, centrifuge, wash, dry, and then under nitrogen at 350 o C roasting 5h. After cooling to room temperature, the carbon-coated cobalt molybdate electrode material can be obtained after mortar grinding.

Embodiment 2

[0023] Dissolve cobalt nitrate and sodium molybdate in a solution composed of water and oleylamine at a molar ratio of 1:1.5, the molar concentration of cobalt nitrate is 0.05 mol / L, and the molar concentration of sodium molybdate is 0.075 mol / L, in which oil The volume of amine accounts for 8% of the solution formed by water and oleylamine. After fully stirring and dissolving, it is transferred to the reaction kettle, 160 oC Hydrothermal reaction for 18 h. After the thermal reaction, centrifuge, wash, dry, and then under nitrogen at 500 o C roasting 3h. After cooling to room temperature, the carbon-coated cobalt molybdate electrode material can be obtained after mortar grinding.

Embodiment 3

[0025] Cobalt chloride and sodium molybdate are dissolved in the solution that water and oleylamine constitute according to the molar ratio of 1:1.5, the molar concentration of cobalt chloride is 0.05 mol / L, and the molar concentration of sodium molybdate is 0.075 mol / L, Wherein the volume of oleylamine accounts for 5% of the solution that water and oleylamine constitute, after fully stirring and dissolving, transfer to the reactor, 160 o C hydrothermal reaction for 18 h. After the thermal reaction, centrifuge, wash, dry, and then under argon at 450 o C roasting 3h. After cooling to room temperature, the carbon-coated cobalt molybdate electrode material can be obtained after mortar grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com