Homogenization thermal-treatment method for ultra-large semi-continuous cast round ingot

A homogeneous heat treatment and super-large size technology, which is applied in the field of aluminum alloy processing, can solve the problems of inability to fully eliminate dendrite structure and low melting point eutectic structure, uneven forging structure, forging billet cracking, etc., and achieve the elimination of low melting point eutectic structure organization, elimination of dendrite organization, and the effect of ensuring comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

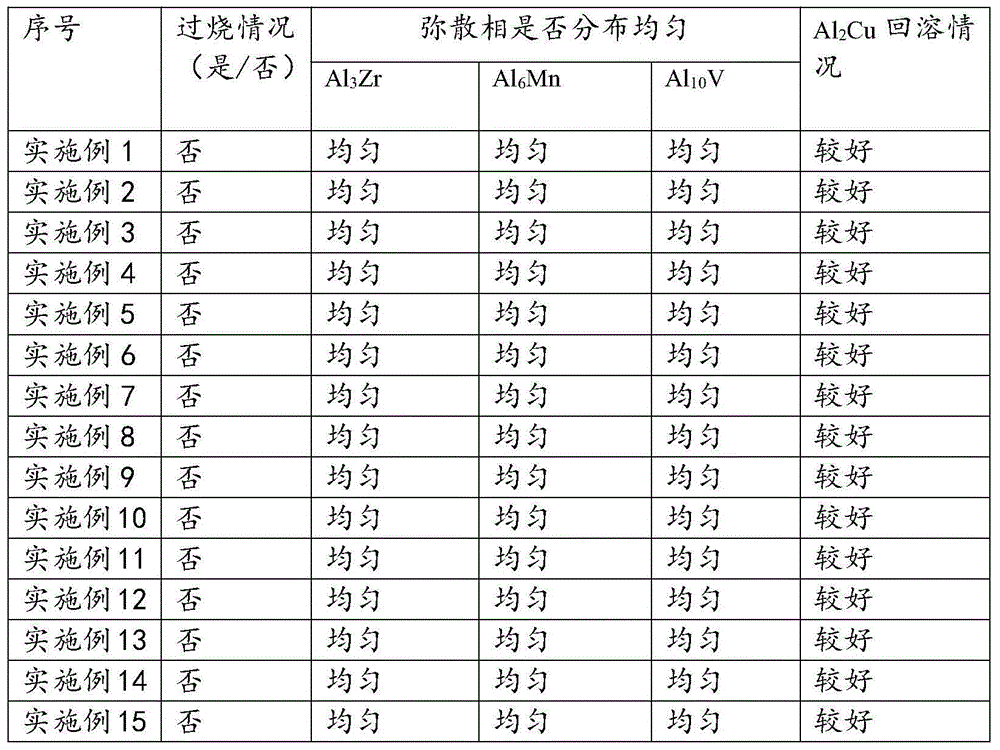

Examples

Embodiment 1

[0047] In this embodiment, the homogenization heat treatment of the 2219 round ingot with a diameter of Φ1320 mm is achieved by the following scheme:

[0048] (1) Put the round ingot sample into the heating device and raise the temperature to 180°C with a heating rate of 14°C / h;

[0049] (2) Raise the temperature of the round ingot from 180°C to 520°C at a heating rate of 60°C / h, and keep it at 520°C for 80 hours;

[0050] (3) Cooling the temperature of the round ingot from 520°C to 360°C at a cooling rate of 58°C / h;

[0051] (4) The temperature of the round ingot is lowered from 360°C to 130°C at a cooling rate of 200°C / h.

[0052] (5) The round ingot was taken out from the heating apparatus, and it was air-cooled from 130° C. to room temperature.

Embodiment 2

[0054] In this embodiment, the homogenization heat treatment of the 2219 round ingot with a diameter of Φ1320 mm and a super large diameter is realized by the following scheme:

[0055] (1) Put the round ingot sample into the heating device to raise the temperature to 180°C, and the heating rate is 10°C / h;

[0056] (2) Heat the round ingot from 180°C to 535°C at a heating rate of 90°C / h, and keep it at 535°C for 30 hours;

[0057] (3) Cool the round ingot from 535°C to 360°C at a cooling rate of 50°C / h;

[0058] (4) Cool the round ingot from 360°C to 130°C at a cooling rate of 80°C / h.

[0059] (5) The round ingot was taken out from the heating apparatus, and it was air-cooled from 130° C. to room temperature.

Embodiment 3

[0061] In this embodiment, the homogenization heat treatment of the 2219 round ingot with a diameter of Φ1320 mm and a super large diameter is realized by the following scheme:

[0062] (1) Put the round ingot sample into the heating device to raise the temperature to 180°C, and the heating rate is 14°C / h;

[0063] (2) First, raise the temperature of the round ingot from 180°C to 300°C at a heating rate of 60°C / h, and keep it at 300°C for 30 hours; then raise the temperature of the round ingot from 300°C to 520°C at a heating rate of 60°C / h , kept at 520°C for 65h.

[0064] (3) Cool the round ingot from 520°C to 360°C at a cooling rate of 48°C / h;

[0065] (4) Cool the round ingot from 360°C to 130°C at a cooling rate of 120°C / h.

[0066] (5) The round ingot was taken out from the heating apparatus, and it was air-cooled from 130° C. to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com