Prefabricated concrete floor

A prefabricated concrete and concrete technology, which is applied to floors, manufacturing tools, building components, etc., can solve problems such as poor compressive capacity and excessive weight of concrete beams, so as to improve service life, reduce relative weight of plates, and increase tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

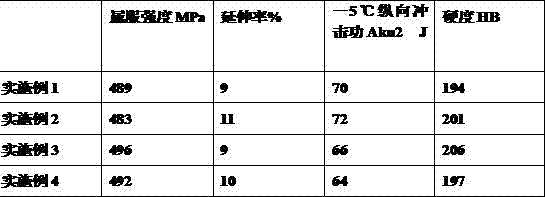

Embodiment 1

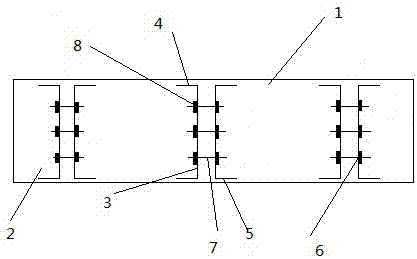

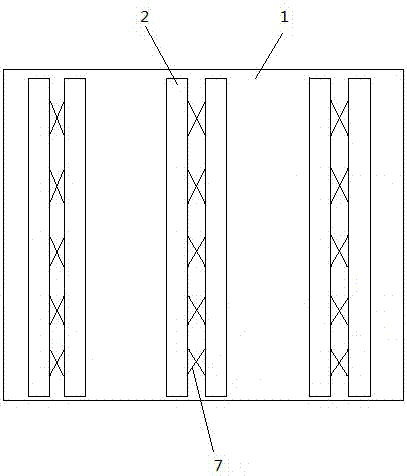

[0022] A prefabricated concrete floor slab, comprising a plurality of longitudinal channel steels, two channel steels are facing away from each other and the openings are set outwards to form a pair of channel steels, the channel steels are provided with a back plate, upper and lower symmetrical upper and lower plates, and a pair of channel steels There are connecting holes on the steel back plate, and the connecting pieces pass through the connecting holes in two horizontal crosses to connect a pair of channel steels. The longitudinal channel steels are poured with concrete to form precast concrete slabs.

[0023]The manufacturing method of the prefabricated concrete floor slab comprises the following steps: First, the channel steel is manufactured, and the chemical composition of the channel steel is: C 0.2%, Zn 4%, Ti 2.5%, V 0.6%, Nb 0.4%, Mg 0.2%, Si 0.2 %; Mn 0.05%; Co 0.045%, Sn 0.01wt%; P ≤ 0.02%; The molten steel is obtained by refining, and the temperature of the mol...

Embodiment 2

[0029] A prefabricated concrete floor slab, comprising a plurality of longitudinal channel steels, two channel steels are facing away from each other and the openings are set outwards to form a pair of channel steels, the channel steels are provided with a back plate, upper and lower symmetrical upper and lower plates, and a pair of channel steels There are connecting holes on the steel back plate, and the connecting pieces pass through the connecting holes in two horizontal crosses to connect a pair of channel steels. The longitudinal channel steels are poured with concrete to form precast concrete slabs.

[0030] The manufacturing method of the prefabricated concrete floor slab comprises the following steps: First, the channel steel is manufactured, and the chemical composition of the channel steel is by weight percentage: C 0.25%, Zn 6%, Ti 2%, V 0.6%, Nb 0.5%, Mg 0.35%, Si 0.35 %; Mn 0.07%; Co 0.04%, Sn 0.02wt%; P ≤ 0.02%; The molten steel is obtained by refining, and the ...

Embodiment 3

[0036] A prefabricated concrete floor slab, comprising a plurality of longitudinal channel steels, two channel steels are facing away from each other and the openings are set outwards to form a pair of channel steels, the channel steels are provided with a back plate, upper and lower symmetrical upper and lower plates, and a pair of channel steels There are connecting holes on the steel back plate, and the connecting pieces pass through the connecting holes in two horizontal crosses to connect a pair of channel steels. The longitudinal channel steels are poured with concrete to form precast concrete slabs.

[0037]The manufacturing method of the prefabricated concrete floor slab comprises the following steps: First, the channel steel is manufactured, and the chemical composition of the channel steel is by weight percentage: C 0.3%, Zn 4%, Ti 2%, V 0.5%, Nb 0.5%, Mg 0.3%, Si 0.25 %; Mn 0.07%; Co0.04%, Sn 0.01wt%; P≤0.02%; RH refining to obtain molten steel, control the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com