Rapid superficial layer carburizing process for prepared carbon potential of large- and medium-scale furnace body

A large and medium-sized, carbon-potential technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of difficult control of layer depth, low hardness, large fluctuation of effective hardened layer, etc., and achieve low cost , high utilization rate of equipment, and stable quality of seepage layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Steel parts made of 20CrMn

[0022] Part Name: Screw Ball Seat

[0023] Material: 20CrMn

[0024] Technical requirements: carburized layer depth 0.5 ~ 0.7mm

[0025] Surface hardness: 59~63HRC

[0026] Hardness in quenching depth: 550HV1

[0027] Preset carbon potential: 1.0~1.2

[0028] Carburizing temperature: 850~880℃

[0029] Carburizing time: 90-120min, adjust to reduce carbon potential before firing

[0030] After carburizing and quenching, the surface hardness is 62~64HRC

[0031] After tempering, the surface hardness is 61~62HRC

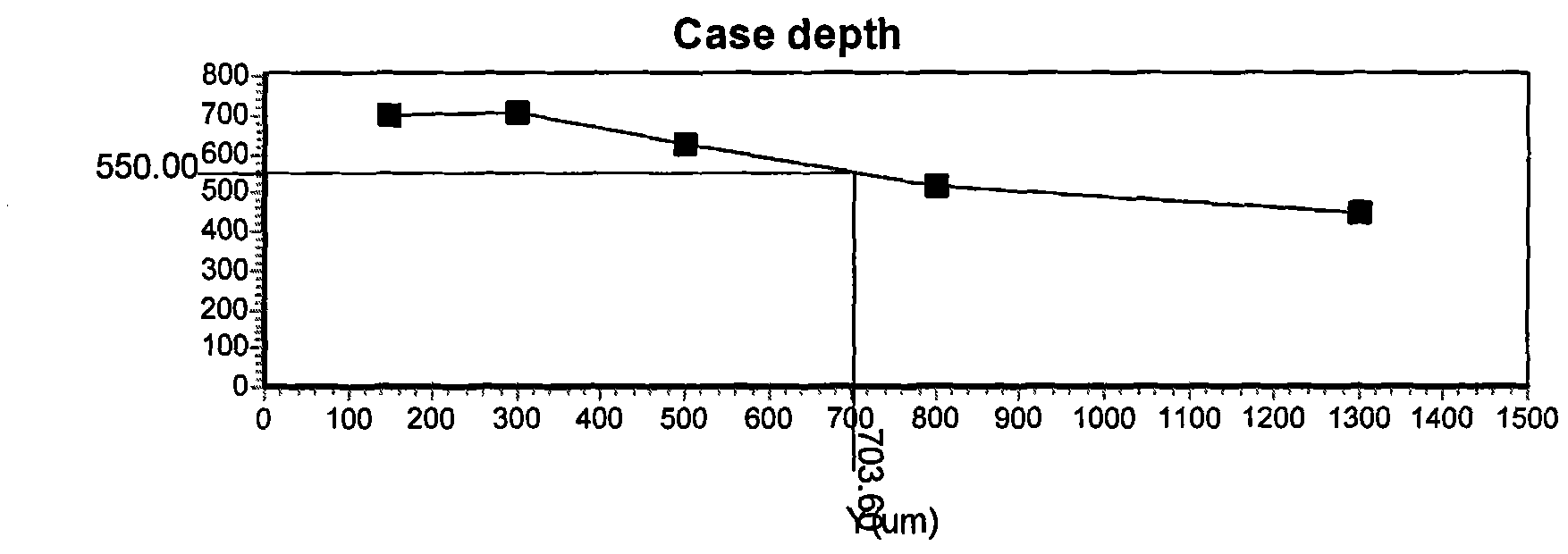

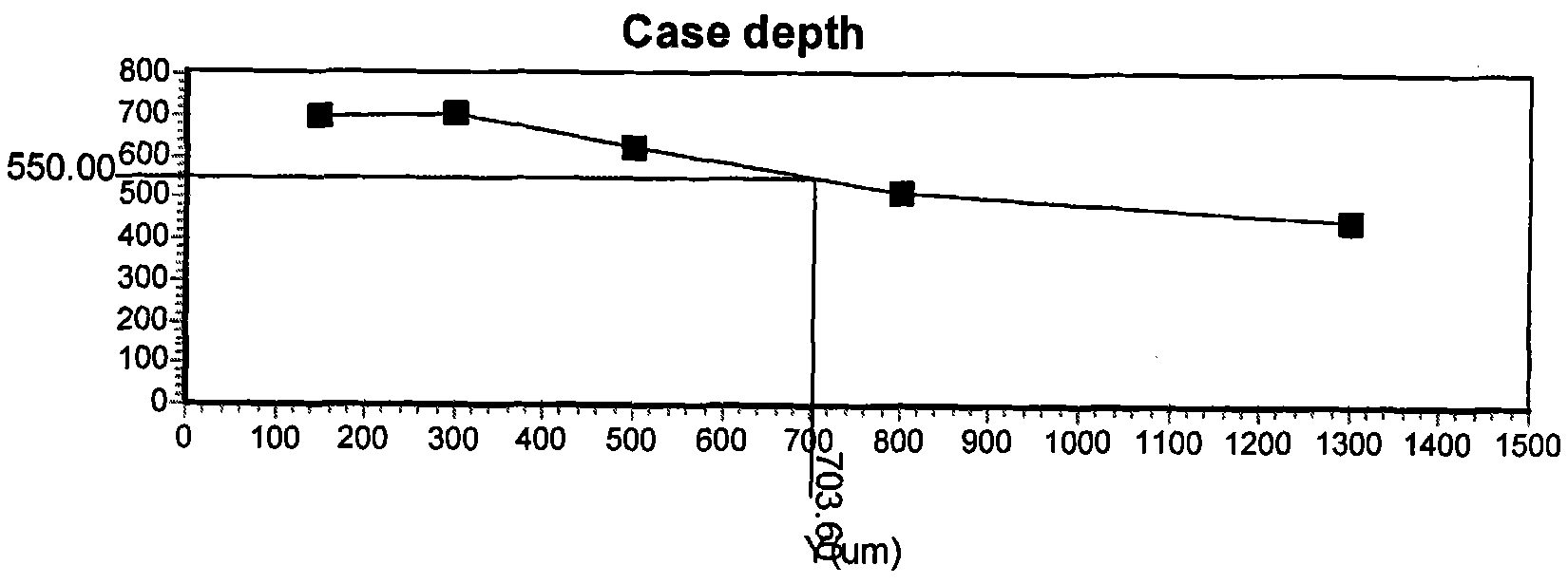

[0032] Effective hardened layer depth 0.70mm

[0033] The distribution of the effective hardened layer is shown in the appendix figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com