Solid oxide fuel cell and preparation method thereof

A solid oxide and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve problems such as not taking into account the cathode part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

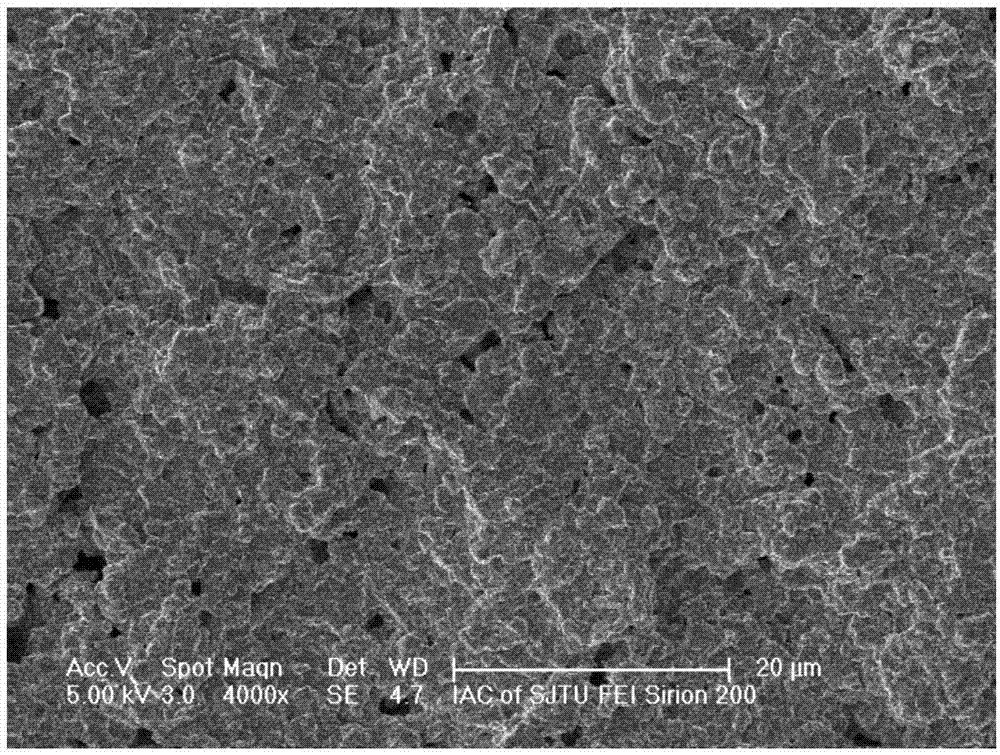

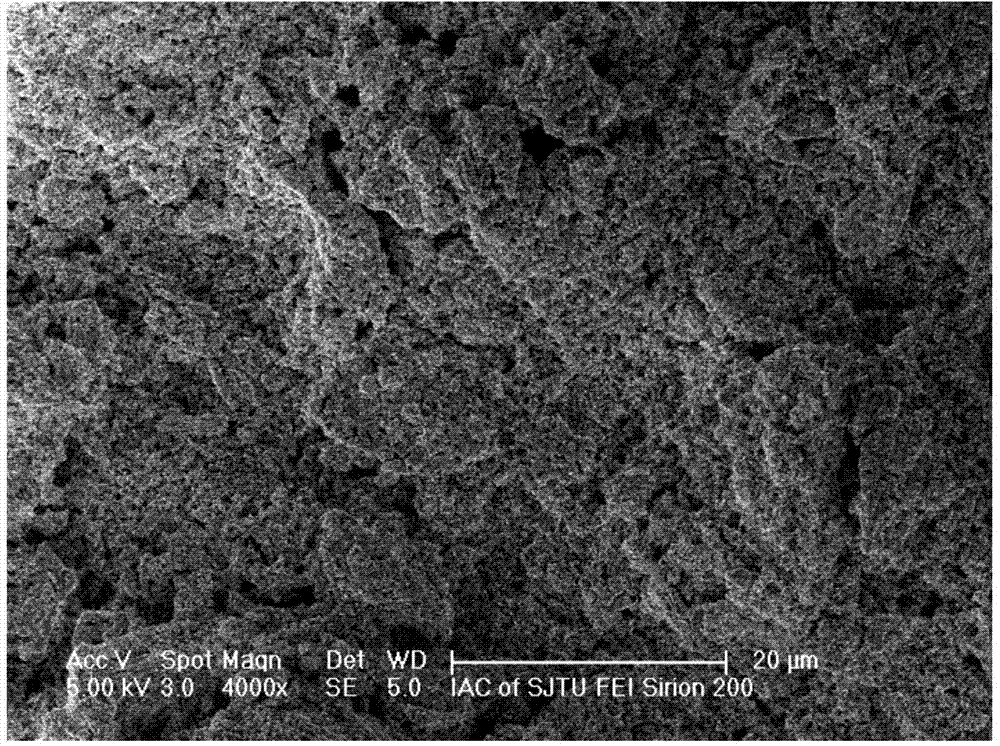

Image

Examples

Embodiment 1

[0065] (1) Mix 80 grams of homemade La 0.2 Sr 0.7 TiO 3 Add the powder and 20 grams of starch into the ball mill tank, then add 110 grams of butanone and ethanol mixed solvent and 3 grams of triethyl phosphate in a weight ratio of 3:2, and use a planetary ball mill at a speed of 300 rpm for 8 hours to mix. 15 grams of polyvinyl butyral, 6 grams of dibutyl phthalate and 6 grams of polyethylene glycol 200 were added to the slurry mixed by ball milling, and ball milled for 16 minutes with a planetary ball mill at a speed of 300 rpm. hours to mix. The above-mentioned final ball-milled slurry was subjected to vacuum degassing treatment for 30 minutes, and cast on a tape casting machine to make perovskite La 0.2 Sr 0.7 TiO 3 The green body of the anode support body, the thickness of the green body of the anode support body after drying is 1000 μm.

[0066](2) ethyl cellulose is dissolved in terpineol, and the ethyl cellulose terpineol mixed solution that ethyl cellulose conten...

Embodiment 2

[0078] (1) Add 70 grams of La 0.2 Sr 0.7 TiO 3 Add the powder and 30 grams of starch into the ball mill tank, then add 110 grams of butanone and ethanol mixed solvent and 3 grams of triethyl phosphate in a mass ratio of 3:2, and use a planetary ball mill at a speed of 300 rpm for 8 hours to mix. 18 grams of polyvinyl butyral, 6 grams of dibutyl phthalate and 6 grams of polyethylene glycol 200 were added to the slurry mixed by ball milling, and ball milled for 16 minutes with a planetary ball mill at a speed of 300 rpm. hours to mix. The above-mentioned final ball-milled slurry was subjected to vacuum degassing treatment for 30 minutes, and cast on a tape casting machine to make perovskite La 0.2 Sr 0.7 TiO 3 The green body of the anode support body, the thickness of the green body of the anode support body after drying is 1000 μm.

[0079] (2) According to the step (2) of Example 1, the ethyl cellulose terpineol solution was prepared, the anode functional layer and the e...

Embodiment 3

[0087] (1) carry out perovskite La according to embodiment 1 0.2 Sr 0.7 TiO 3 Preparation of anode support green body and ethylcellulose terpineol solution.

[0088] (2) 1 gram of homemade 10Sc1CeSZ and 1.5 grams of La 0.2 Sr 0.7 TiO 3 The mixed powder was added to 9 milliliters of 2wt% ethylcellulose terpineol solution, ground for 1 hour to obtain a stable and uniform slurry, and the prepared mixed slurry was evenly deposited on the raw material of the anode support on a screen printing machine. The first layer of anode functional layer is formed on the blank. Add the mixed powder of 1 gram of 10Sc1CeSZ and 1.5 gram of NiO to 9 milliliters of 2wt% ethylcellulose terpineol solution, grind for 1 hour to obtain a stable and uniform slurry, and prepare the mixed slurry on a screen printing machine uniformly deposited on the anode support body green body to form the second anode functional layer. Add 4 grams of 10Sc1CeSZ powder to 6 ml of 3wt% ethylcellulose terpineol solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com