Hydro-denitrification catalyst for coal tar and preparation method thereof

A hydrodenitrogenation and catalyst technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Hydrodenitrogenation performance, the effect of reducing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

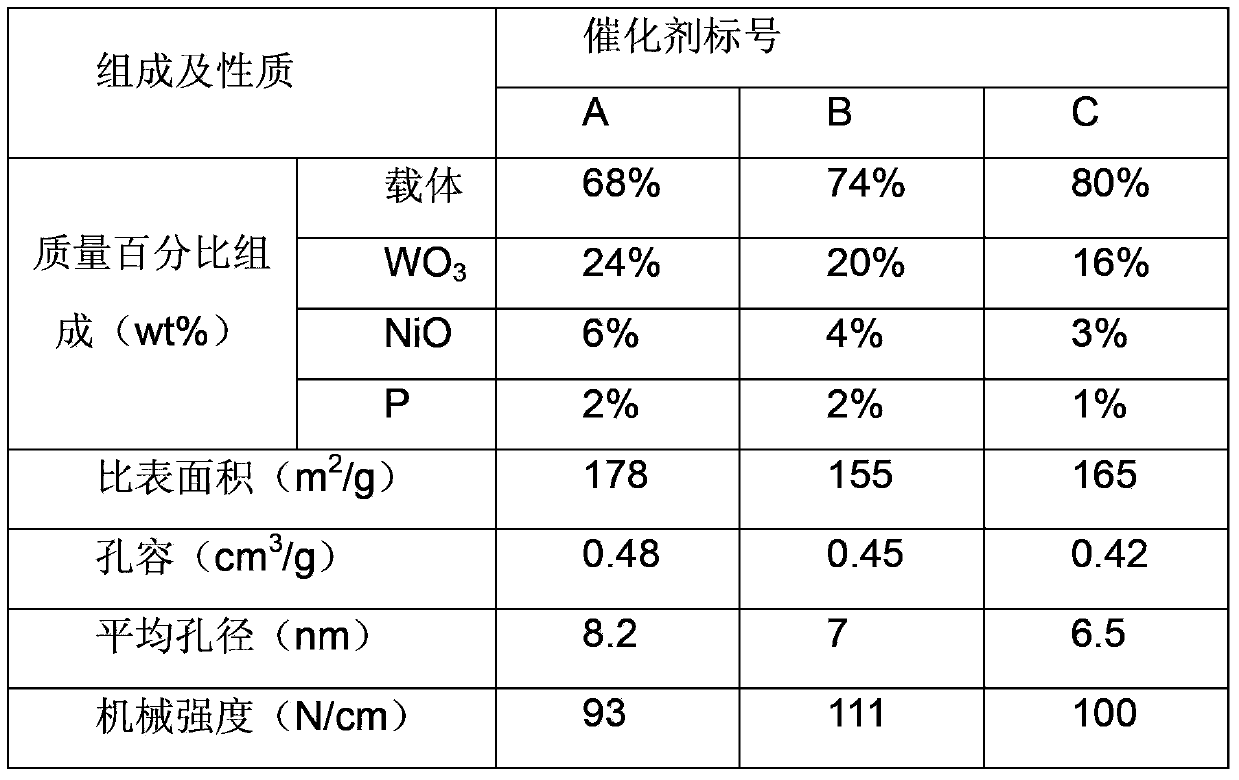

Examples

preparation example Construction

[0026] The preparation method of catalyst of the present invention comprises:

[0027] The first step is to prepare the carrier:

[0028] 1) A certain number of parts by weight of activated carbon, alumina and Hβ molecular sieves are respectively ball milled to obtain a powder with a particle size of less than 0.046mm, and after drying at a temperature of 100-120°C for 2-6 hours, the carrier raw material powder is obtained for use;

[0029] 2) Add an aqueous organic acid solution (one of acetic acid, malonic acid or citric acid, with a concentration of 20-80vol.%) to the alumina powder and Hβ molecular sieve powder, and stir for 20-40 minutes to mix them Uniform; then add activated carbon powder and binder (one of sucrose, carboxymethyl cellulose or starch), continue to stir for 20-40 minutes to mix well, and let it stand in a closed container for 20-28 hours, then press or squeeze Out of shape;

[0030] 3) The formed carrier is dried at 100-120°C for 2-6h, and then placed i...

Embodiment 1

[0035] Weigh 54g of alumina powder milled to less than 0.046mm, 16g of Hβ molecular sieve powder with equal particle size, add 30cm 3 Acetic acid aqueous solution with a concentration of 80%, stirred for 40 minutes to make the mixture uniform, then added 24g of activated carbon powder with the same particle size, and added 30g of sucrose as a binder, and continued to stir for 40 minutes to make the mixture uniform. The obtained black viscous substance was left to stand in a closed container for 28 hours, and then pressed into tablets. Dry the obtained molding at 120°C for 2h, and then dry it at 600°CN 2 Calcined in the atmosphere for 2 hours, and after cooling, 101 g of the finished catalyst carrier was obtained. Calculated on a dry basis, alumina accounted for 53% of the total weight of the carrier, activated carbon accounted for 31% of the total weight of the carrier, and Hβ molecular sieve accounted for 16% of the total weight of the carrier.

[0036] Add 44g of ammonium m...

Embodiment 2

[0039] Weigh 68g of alumina powder milled to less than 0.046mm, 12g of Hβ molecular sieve powder with equal particle size, add 27cm 3 Concentration of 50% malonic acid aqueous solution, stir for 30 minutes to mix evenly, then add 16g of activated carbon powder with the same particle size, and add 20g carboxymethyl cellulose as a binder at the same time, continue to stir for 30min to mix evenly. The obtained black viscous substance was left to stand in a closed container for 24 hours, and then pressed into tablets. Dry the obtained molding at 110°C for 4h, and then at 500°CN 2 Calcined in the atmosphere for 4 hours, and after cooling, 100 g of the finished catalyst carrier was obtained. Calculated on a dry basis, alumina accounted for 68% of the total weight of the carrier, activated carbon accounted for 20% of the total weight of the carrier, and Hβ molecular sieve accounted for 12% of the total weight of the carrier.

[0040] Add 33g of ammonium metatungstate, the precursor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com