Negative-pole active material and preparation method thereof as well as lithium ion battery using negative-pole active material

A negative electrode active material and carbon material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing the cycle performance and charge-discharge efficiency of lithium-ion batteries, shortening the service life of batteries, collapse, pulverization, etc., to achieve Improve cycle performance and charge and discharge efficiency, avoid liquid absorption expansion, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

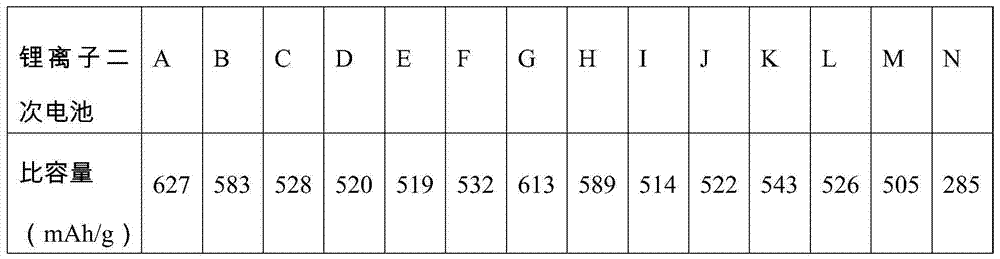

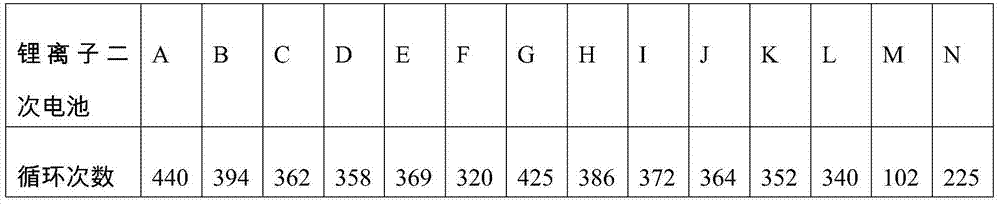

Examples

Embodiment 1

[0044] (1) Mix 2.5g of lithium carbonate, 0.8g of alumina, 7.1g of titanium oxide, 18g of ammonium dihydrogen phosphate, 2000g of deionized water and 100g of silicon powder with a particle size of 2μm and seal it, and react at a constant temperature of 100°C for 24h , to obtain the precursor suspension;

[0045] (2) After filtering, washing and drying the above-mentioned precursor suspension, calcining at 600°C for 12 hours in a nitrogen atmosphere to obtain the coating material;

[0046] (3) Add 900g of graphite with a particle size of 2μm and 120g of coating material to 2100g of a mixture composed of ethanol and thiophene (20:1 by weight) and mix evenly to form a stable solid-liquid mixture, then vacuum-dry at 50°C , and then calcined at 300° C. for 12 h in a nitrogen atmosphere to obtain negative electrode active material A.

[0047] In this embodiment, the coating material is composed of the second material coated on silicon, take a small amount of the second material on ...

Embodiment 2

[0051] (1) Mix 2.6g of lithium nitrate, 1.24g of lithium hydroxide, 4.1g of lanthanum oxide, 6.2g of germanium oxide, 14.6g of lithium phosphate, 2000g of deionized water, and 80g of tin powder with a particle size of 3μm and seal them up at 120 Constant temperature reaction at ℃ for 20 hours to obtain precursor suspension;

[0052] (2) After filtering, washing and drying the above-mentioned precursor suspension, calcining at 800°C for 10 hours in an argon atmosphere to obtain the coating material;

[0053] (3) Add 1100g of hard carbon with a particle size of 5 μm and 100g of coating material to a 1800g mixture of acetone, tetrahydrofuran and polypyrrole (8.5:8.5:1 by weight) and mix evenly to form a stable solid-liquid mixture. Vacuum-dried at 60° C., and then calcined at 400° C. for 10 h in an argon atmosphere to obtain negative electrode active material B.

[0054] In this embodiment, the coating material is composed of the second material coated on tin. A small amount of ...

Embodiment 3

[0058] (1) Mix 7.9g of lithium chloride, 3.3g of chromium oxide, 16.1g of zirconia, 18.5g of phosphorus pentoxide, 2200g of deionized water and 120g of germanium powder with a particle size of 5μm and seal it, and keep the temperature at 150°C React for 18 hours to obtain the precursor suspension;

[0059] (2) After filtering, washing and drying the above-mentioned precursor suspension, roast it in a helium atmosphere at 1000°C for 4 hours to obtain the coating material;

[0060] (3) Add 900g of soft carbon with a particle size of 10μm and 160g of coating material to a 1950g mixture of tetrahydrofuran and polytetrafluoroethylene (12:1 by weight) and mix evenly to form a stable solid-liquid mixture. °C in vacuum, and then calcined at 500 °C for 8 h in a nitrogen atmosphere to obtain negative electrode active material C.

[0061] In this embodiment, the coating material is composed of the second material coated on germanium, and a small amount of the second material on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Electronic conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com