Preparation method of curved-surface fly's-eye lens array

A technology of lens array and microlens array, which is applied in the field of optical bionics, can solve the problems of device sealing, complicated process, complex process, etc., and achieve the effect of low price, simple preparation process and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

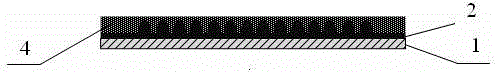

[0026] A method for preparing a curved surface bionic fly-eye lens array by magnetic field induction, the specific process is:

[0027] In this example, the mass fraction of carbonyl iron powder inclusions was chosen to be 70% for the preparation of the magnetoelastic film, mainly because when the volume fraction of inclusions is low, the force of the magnetoelastic film and the external magnetic field after magnetization is small, and the deformation produced is relatively small. Small; when the inclusion volume fraction is higher, the bending stiffness of the magnetoelastic film increases and it is not easy to deform.

[0028] Spin-coat SU8 or other photoresists on other substrates 1 such as silicon or glass;

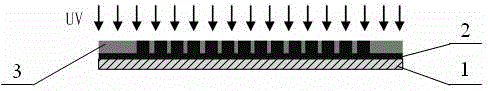

[0029] Use a mask to expose it to ultraviolet light for 3 engravings, and after development, a series of cylindrical structures with a diameter of 10 μm are formed, such as figure 1 shown.

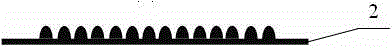

[0030] Put the cylinder in an oven at 160°C and bake for 20 minutes. Under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com