Graphene oxide, preparation method and application thereof

A graphene and natural graphite technology, applied in graphene oxide and its preparation, in the field of removing pollutants in water, can solve the problems of no adsorption of bisphenol A, single surface structure, poor effect, etc., achieve complete adsorption and ensure the degree of oxidation , the effect of easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 graphene oxide

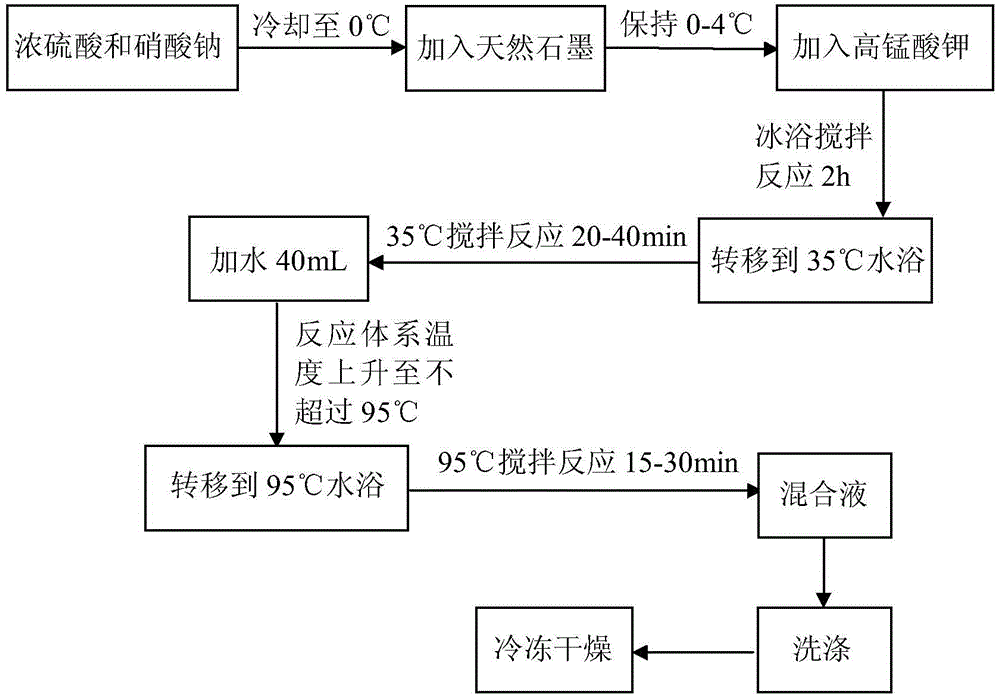

[0048] Present embodiment provides a kind of graphene oxide, such as figure 1 As shown, it was prepared by the following method:

[0049] (1) Oxidation:

[0050] a. Low temperature reaction: Add 20mL of concentrated sulfuric acid and a magnet to a 250ml round bottom flask, slowly add 1g of sodium nitrate under stirring at 40-60rpm, after it dissolves, cool in an ice bath to 0°C, and continue stirring , then add 1g of 325-mesh natural graphite, and then add 6g of potassium permanganate to ensure that the temperature of the reaction system is at 0-4°C, keep warm and react for 2h under slow stirring;

[0051] b. Medium-temperature reaction: remove the ice bath, use a 35°C water bath, continue to stir, control the temperature of the reaction system at 35±5°C, react for 20-40min, then slowly drop 40mL deionized water into the reaction system to keep the temperature of the reaction system Rise up, and control the temperature...

Embodiment 2

[0058] Embodiment 2 is to the adsorption and analysis method of heavy metal

[0059] Preparation of standard solution: use 2100mL Instrument Calibration Standard produced by Perkin Elmer.Inc., in which the concentration of each element is 100ppm, take 1mL of the original solution with a pipette, dilute with pure water to obtain a 1ppm metal ion mixed solution.

[0060] Experimental steps:

[0061] 1. Add 100mL of pure water into a plastic bottle, insert a magnet, add 50mg of the graphene oxide prepared in Example 1, stir and ultrasonically properly disperse it;

[0062] 2. Add 2mL of pre-prepared 1ppm heavy metal solution with a pipette gun, so that the concentration of heavy metal ions in the system is 20ppb, start timing from the time of addition, and take out 4mL at 5min, 15min, 25min, 50min, 100min, 150min and 200min Mix the liquid, close the lid when not taking the solution to prevent the solution from evaporating, centrifuge immediately after taking it out, and centrifu...

Embodiment 3

[0065] Embodiment 3 to the adsorption and analysis method of BPA

[0066] Instrument model: high performance liquid chromatography (Waters 2695), column model: C-18 column (Waters XBridge), flow rate: 1mL / min, mobile phase: a mixed solution of 70% methanol and 30% water, detector model: fluorescence Detection (Waters 2475), excitation wavelength: 278nm, fluorescence wavelength 315nm.

[0067] Experimental steps:

[0068] 1. Prepare the graphene oxide aqueous solution prepared by the embodiment 1 of 0.5 mg / mL in a 250mL beaker, and the specific operations are the same as in the embodiment 2;

[0069] 2. Add 0.2mL of pre-prepared 10ppm BPA methanol solution with a glass micro-injector, so that the BPA concentration in the system is 20ppb, start timing from the time of addition, and take out 4mL at 5min, 15min, 25min, 50min and 100min Mix the liquid, centrifuge immediately after taking it out, centrifuge at 11000rpm for 10 minutes, take out the supernatant and filter it with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com