Preparation method of BiFeO3 porcelain added with Bi2O3-B2O3-SiO2 glass

A bi2o3-b2o3-sio2, glass technology, applied in the field of ceramic dielectric materials, can solve the problems of difficult detection of antiferromagnetism, large leakage conduction current, low dielectric constant, etc., and achieve saturation hysteresis loop and dielectric loss The effect of reducing and increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of added Bi 2 o 3 -B 2 o 3 -SiO 2 Glass BiFeO 3 The preparation method of pottery, comprises the following steps:

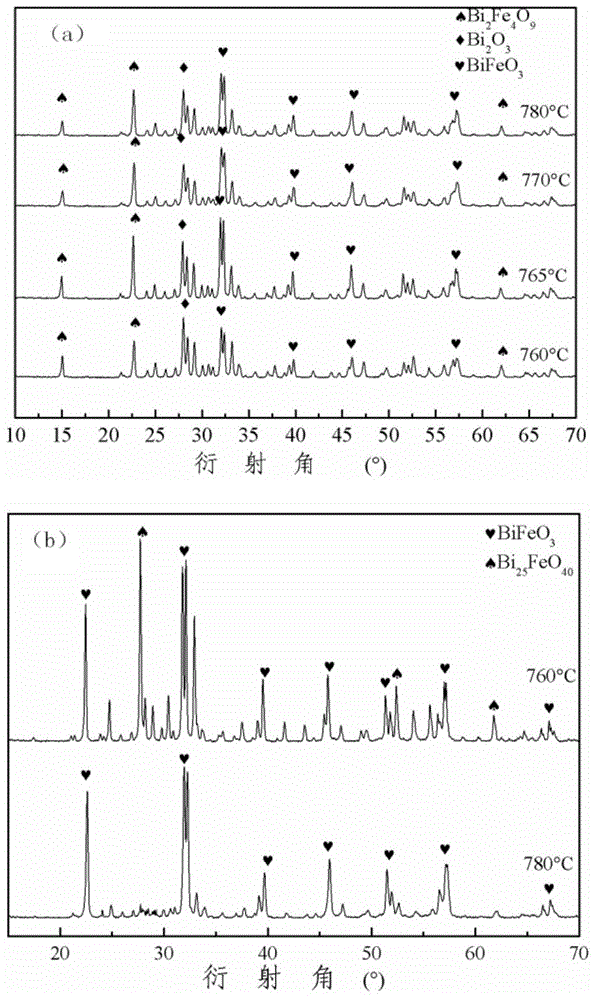

[0035] Step 1: Preparation of BiFeO 3 : According to the molar ratio of 1:1 Bi 2 o 3 and Fe 2 o 3 Mix to form a blend, then ball mill, dry, and briquette the blend, then place it at 780°C for 1 hour to form a pure phase of BiFeO 3 Powder;

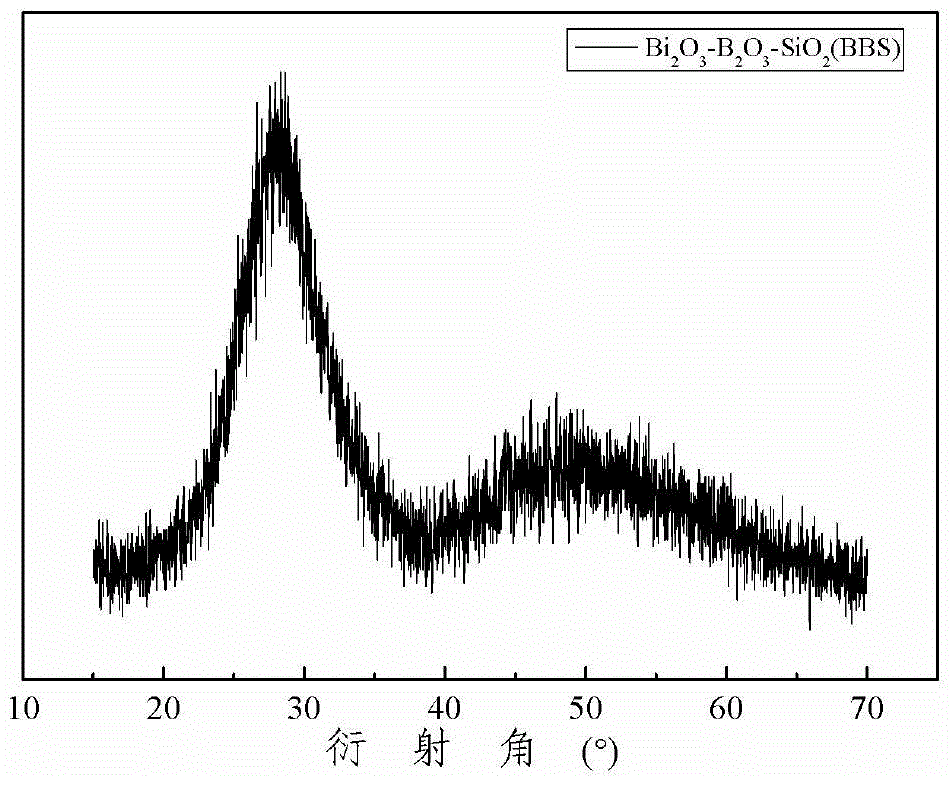

[0036] Step 2: Preparation of Bi 2 o 3 -B 2 o 3 -SiO 2 Glass:

[0037] a. Burn the corundum crucible to 900-920°C in a muffle furnace;

[0038] b. Bi according to the molar ratio 2 o 3 :B 2 o 3 :SiO2 2 = 65:10:25 ratio for batching;

[0039] c. Put the prepared material into the crucible and continue to burn to 1250-1270°C, then keep it warm for 1-1.5h, after water quenching, grinding, and passing through an 80-mesh sieve to get Bi 2 o 3 -B 2 o 3 -SiO 2 Glass;

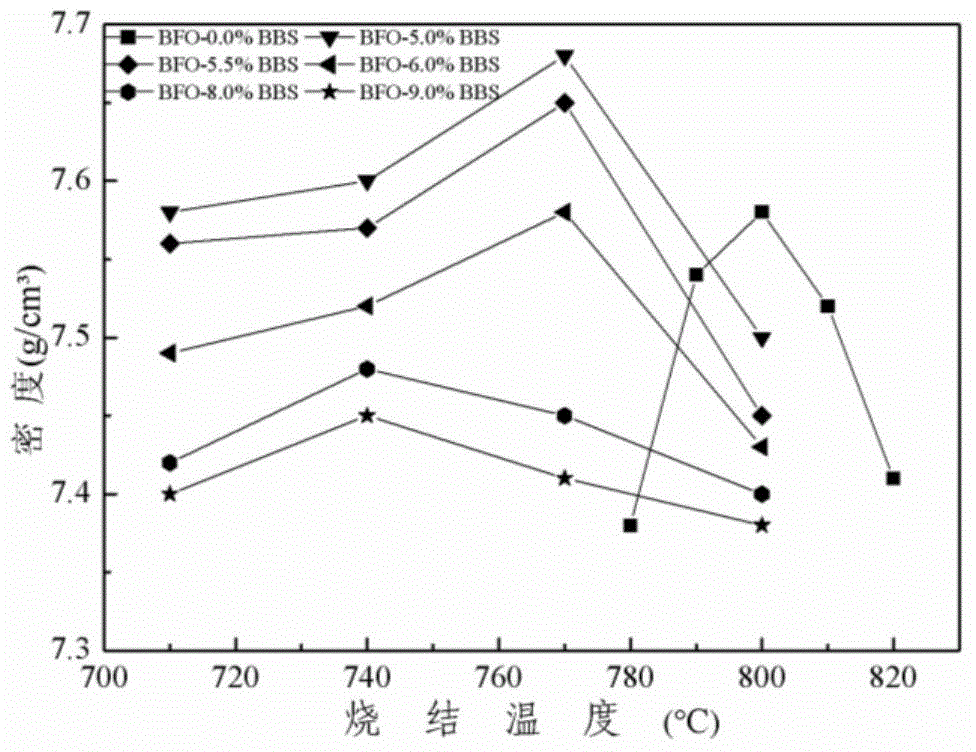

[0040] Step 3: Bi obtained in Step 2 2 o 3 -B 2 o 3 -SiO 2 Glass is added to the BiFeO obtained in step 1 by mass perce...

Embodiment 1

[0051] BiFeO of the present invention 3 Based on environmental protection relaxation ceramic dielectric material, its formula is BiFeO 3 +x wt% Bi 2 o 3 -B 2 o 3 -SiO 2 , where x=5, x is the mass percentage.

[0052] Step 1: Preparation of BiFeO 3 : According to the molar ratio of 1:1 Bi 2 o 3 and Fe 2 o 3 Mix to form a blend, then ball mill, dry, and briquette the blend, then place it at 780°C for 1 hour to form a pure phase of BiFeO 3 Powder;

[0053] Step 2: Preparation of Bi 2 o 3 -B 2 o 3 -SiO 2 Glass:

[0054] a. Burn the corundum crucible to 900°C in a muffle furnace;

[0055] b. Bi according to the molar ratio 2 o 3 :B 2 o 3 :SiO2 2 = 65:10:25 ratio for batching;

[0056] c. Put the prepared material into the crucible and continue to burn to 1250°C, then keep it warm for 1 hour, quench in water, grind, and pass through an 80-mesh sieve to get Bi 2 o 3 -B 2 o 3 -SiO 2 Glass;

[0057] Step 3: Bi obtained in Step 2 2 o 3 -B 2 o 3 -SiO 2 ...

Embodiment 2

[0061] BiFeO of the present invention 3 Based on environmental protection relaxation ceramic dielectric material, its formula is BiFeO 3 +x wt% Bi 2 o 3 -B 2 o 3 -SiO2 , wherein x=5.5, x is the mass percentage.

[0062] Step 1: Preparation of BiFeO 3 : According to the molar ratio of 1:1 Bi 2 o 3 and Fe 2 o 3 Mix to form a blend, then ball mill, dry, and briquette the blend, then place it at 780°C for 1 hour to form a pure phase of BiFeO 3 Powder;

[0063] Step 2: Preparation of Bi 2 o 3 -B 2 o 3 -SiO 2 Glass:

[0064] a. Burn the corundum crucible to 910°C in a muffle furnace;

[0065] b. Bi according to the molar ratio 2 o 3 :B 2 o 3 :SiO2 2 = 65:10:25 ratio for batching;

[0066] c. Put the prepared material into the crucible and continue to burn to 1260°C and keep it warm for 1.5h. After water quenching, grinding, and passing through an 80-mesh sieve, Bi is obtained. 2 o 3 -B 2 o 3 -SiO 2 Glass;

[0067] Step 3: Bi obtained in Step 2 2 o 3 -B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com