Ceramized polyolefin material and preparation method thereof

A polyolefin material, ceramization technology, applied in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of ceramic strength, compactness difficult to achieve expectations, high processing temperature, low residual strength and other problems , to meet the requirements of industrial scale-up production, to meet the requirements of soft laying, and to achieve the effect of concise preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

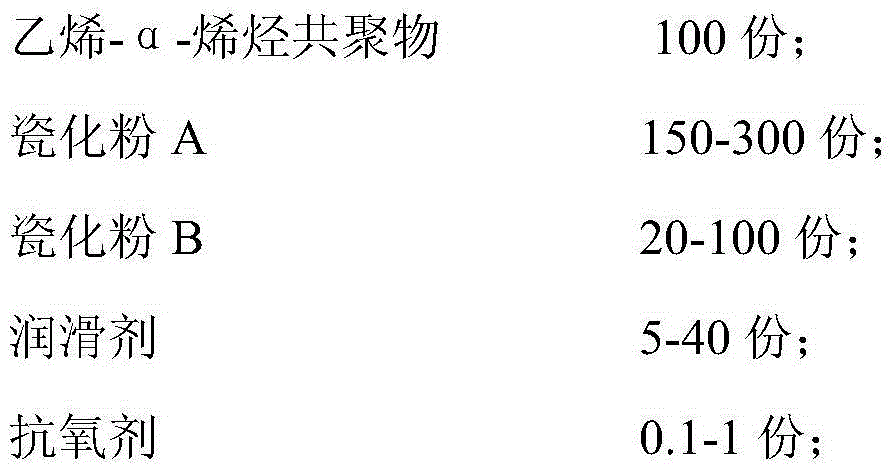

Embodiment 1

[0018] 100 parts of ethylene-α-propylene copolymer weighed in parts by weight, porcelain powder A is attapulgite 180 parts, porcelain powder B is 15 parts each of zinc borate and ammonium borate, and lubricant is 8 parts of stearic acid. and 10100.3 parts of antioxidant are put into the internal mixer for mixing (also known as internal mixing), when the temperature is 100°C, the material is discharged and introduced into the twin-screw extruder through the conical feeding hopper for melt extrusion, and the twin-screw The temperature of zone 1 to zone 9 of the extruder is 60°C for zone 1, 70°C for zone 2, 80°C for zone 3, 85°C for zone 4, 90°C for zone 5, 90°C for zone 6, 90°C for zone 7, and 90°C for zone 8. 95°C, nine zone 95°C, head temperature 100°C, after exiting the twin-screw extruder, cold cut to obtain ceramic polyolefin material.

Embodiment 2

[0020] 50 parts of ethylene-α-butene copolymer, 25 parts of ethylene-α-octene copolymer, 25 parts of ethylene-α-hexene copolymer, and 80 parts of glass fiber A are , 80 parts of alumina nanotubes and 80 parts of calcium carbonate whiskers, 60 parts of vitrified powder B, namely borax, 11 parts of lubricants, namely calcium stearate and zinc stearate, 168 parts of antioxidant and 300 parts of antioxidant Put 0.5 parts into the internal mixer for mixing (also known as internal mixing), when the temperature reaches 115°C, the material is discharged and introduced into the twin-screw extruder through the conical feeding hopper for melting and extrusion. One part of the twin-screw extruder The temperature in Zone 1 to Zone 9 is 50°C for Zone 1, 65°C for Zone 2, 70°C for Zone 3, 80°C for Zone 4, 95°C for Zone 5, 95°C for Zone 6, 95°C for Zone 7, 95°C for Zone 8, and 95°C for Zone 9. 90°C, head temperature 95°C, after exiting the twin-screw extruder, cold cut to obtain ceramic polyol...

Embodiment 3

[0022]100 parts of ethylene-alpha-propylene copolymer, porcelain powder A, 100 parts of sericite, 100 parts of muscovite and 100 parts of phlogopite, porcelain powder B, low-melting borate glass powder Or 100 parts of low-melting silicate glass powder, 2.5 parts of octyl stearate as a lubricant, 2.5 parts of liquid paraffin and 10760.1 parts of antioxidant are put into the internal mixer for mixing (also known as internal mixing). When the temperature is 105°C, the material is discharged and introduced into the twin-screw extruder through the conical feeding hopper for melt extrusion. The temperatures of the first zone to the ninth zone of the twin-screw extruder are respectively 55°C for the first zone, 60°C for the second zone, and 75°C for the third zone. ℃, the fourth zone is 90°C, the fifth zone is 92°C, the sixth zone is 92°C, the seventh zone is 92°C, the eighth zone is 92°C, the ninth zone is 92°C, the head temperature is 98°C, after exiting the twin-screw extruder, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com