Wear resistant carbide coating and production method thereof

A carbide and coating technology, applied in coating, metal material coating process, etc., can solve problems such as low production efficiency, low coating bonding strength, and demanding production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1: the preparation method of carbide coating, comprises the steps:

[0081] 1. Prepare a tungsten plate 1 first, wherein the purity of tungsten should be controlled at 99.7%. The tungsten plate 1 is first surface treated, and the steps are as follows:

[0082] The first step is pickling, choose 300ml / L hydrochloric acid, and then rinse with running water;

[0083] In the second step of pickling, choose 300ml / L hydrofluoric acid, and then rinse with running water;

[0084] The third step is surface grinding, using 800 mesh Al 2 o 3 Sandpaper and finally ultrasonic cleaning with alcohol.

[0085] The thickness of the tungsten plate 1 is controlled at 0.2mm.

[0086] 2. The Q275A substrate is smelted into molten steel, and the temperature is controlled at 1630°C.

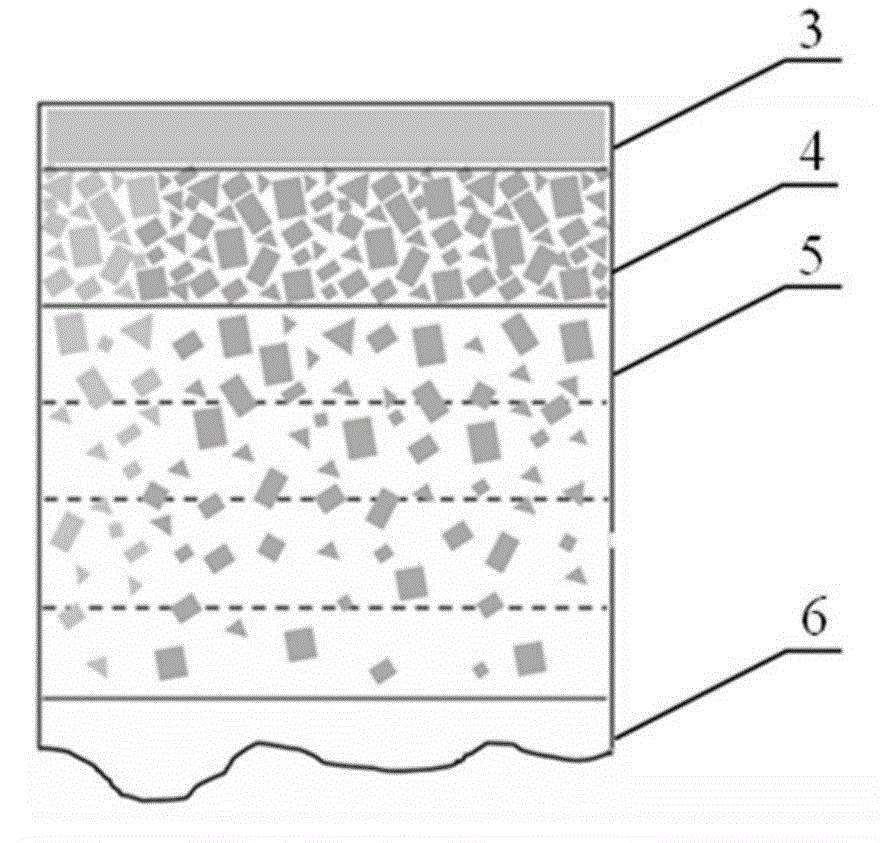

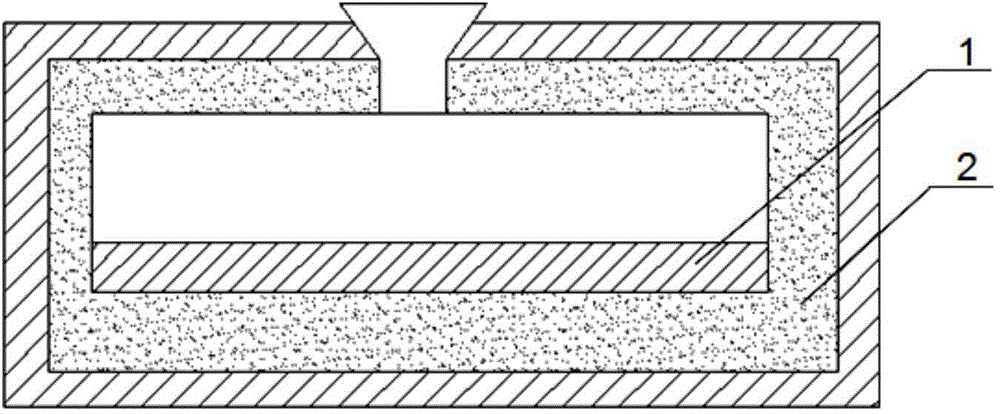

[0087] 3. Pour the above-mentioned molten steel into the sand mold 2 on which the above-mentioned tungsten plate 1 is placed, such as figure 1 As shown, the pouring temperature is controlled at ...

Embodiment 2

[0095] Embodiment 2: the preparation method of carbide coating, comprises the steps:

[0096] 1. Prepare a tungsten plate 1 first, in which the purity of tungsten should be controlled at 99.8%.

[0097] The tungsten plate 1 should be surface treated first, the steps are as follows:

[0098] In the first step of pickling, choose 60ml / L phosphoric acid, and then rinse with running water;

[0099] In the second step of pickling, choose 200ml / L sulfuric acid, and then rinse with running water;

[0100] The third step is surface grinding, using 1000 mesh Al 2 o 3 Sandpaper and finally ultrasonic cleaning with alcohol.

[0101] The thickness of the tungsten plate 1 is controlled at 0.8mm.

[0102] 2. The Q255AF base material is smelted into molten steel, and the temperature is controlled at 1630°C.

[0103] 3. Pour the above molten steel into the sand mold 2 with the above tungsten plate 1 placed, the pouring temperature is controlled at 1630°C, the pouring time is 40 seconds,...

Embodiment 3

[0111] Embodiment 3: the preparation method of carbide coating, comprises the steps:

[0112] 1. Prepare a tungsten plate 1 first, in which the purity of tungsten should be controlled at 99.8%. The tungsten plate 1 should be surface treated first, the steps are as follows:

[0113] The first step is pickling, choose 120ml / L hydrogen peroxide, and then rinse with running water;

[0114] In the second step of pickling, choose 240ml / L hydrogen peroxide, and then rinse with running water;

[0115] The third step is surface grinding, using 1200 mesh Al 2 o 3 Sandpaper and finally ultrasonic cleaning with alcohol. The thickness of the tungsten plate 1 is controlled at 1mm.

[0116] 2. Smelt the 45 steel base material into liquid steel, and the temperature is controlled at 1620°C.

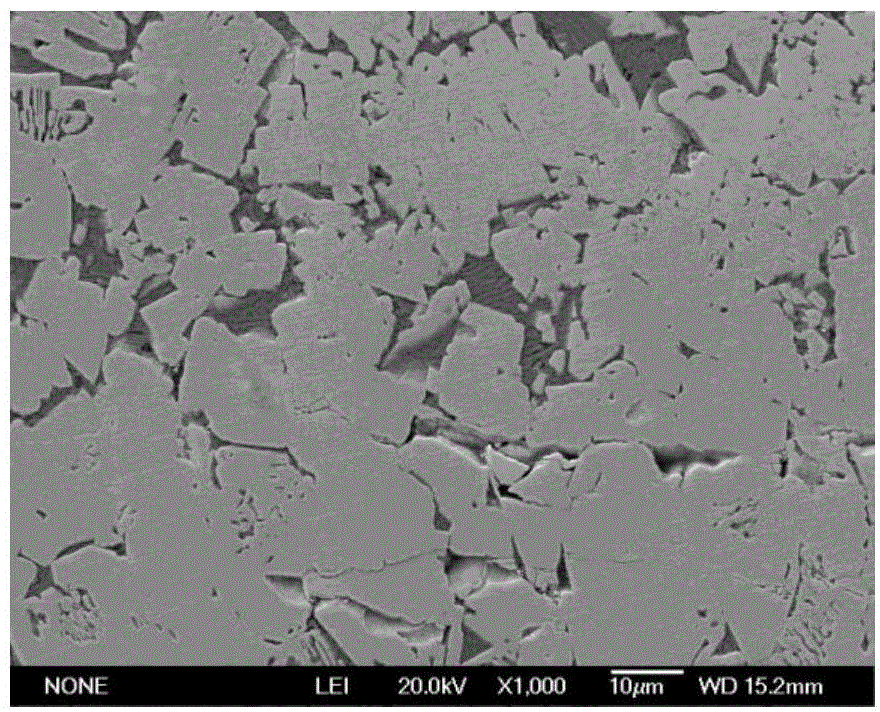

[0117] 3. The above liquid steel is poured into the sand mold 2 with the above tungsten plate 1 placed, the pouring temperature is controlled at 1620°C, after cooling, a composite body with 45 steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com