X90 level heterogeneous structure pipeline steel plate for longitudinal welded pipe and manufacturing method of pipeline steel plate

A technology of multi-phase structure and manufacturing method, which is applied in the field of X90-grade multi-phase structure pipeline steel plate and its manufacturing field for straight seam welded pipes for oil and gas transportation. It can solve the problems of affecting welding performance, high steel plate hardness, and high cost, and improve the safety of use. High stability, high uniform elongation, and low yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

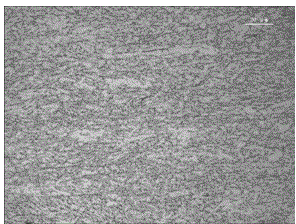

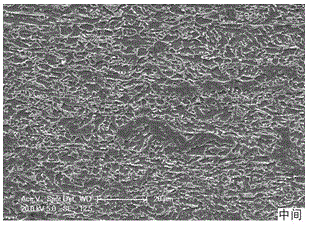

Image

Examples

Embodiment 1

[0059] The X90 grade multi-phase structure pipeline steel for straight seam welded pipes of the present invention has the following components and weight percentages: C: 0.055%, Si: 0.22%, Mn: 1.68%, P: 0.006%, S: 0.0007:%, Nb: 0.07%, Ti: 0.015%, Cu: 0.25%, Cr: 0.27%, Mo: 0.20%, Ni: 0.20%, Al: 0.035%, N: 0.005%, welding crack sensitivity coefficient CE Pcm =0.176.

[0060] It is smelted on a 210-ton converter, and rolled into a wide and thick steel plate with a thickness of 19.6mm, a width of 3750mm, and a length of 12000mm on a 4300mm double-stand rolling production line.

[0061] The specific production process is:

[0062] 1) Molten iron is desulfurized by KR deep, oxygen-blowing decarburization and dephosphorization in 210-ton converter, Si-Ca treatment, and then cast into slabs, control the end point of molten steel S ≤ 0.0008%, P ≤ 0.010%, protection casting, slab cross-sectional size It is 250×2200mm. Control slab quality center segregation C class 0.5, no intermediate...

Embodiment 2

[0075] The X90 grade multi-phase structure pipeline steel for straight seam welded pipes of the present invention has the following components and weight percentages: C: 0.060%, Si: 0.23%, Mn: 1.70%, P: 0.007%, S: 0.0009:%, Nb: 0.073%, Ti: 0.016%, Cu: 0.24%, Cr: 0.27%, Mo: 0.24%, Ni: 0.21%, Al: 0.040%, N: 0.006%, the rest is Fe and unavoidable impurities; welding Crack Sensitivity Coefficient CE Pcm =0.18.

[0076] Follow the steps below to produce:

[0077] 1) Molten iron is desulfurized by KR deep, oxygen-blowing decarburization and dephosphorization in 210-ton converter, Si-Ca treatment, and then cast into slabs, control the end point of molten steel S ≤ 0.0008%, P ≤ 0.010%, protection casting, slab cross-sectional size It is 250×2200mm. Control slab quality center segregation C class 0.5, no intermediate cracks;

[0078] 2) The slab is slowly cooled in the slow cooling pit for 2-3 days;

[0079] 3) The slab is heated, and the heating temperature is controlled at 1160°...

Embodiment 3

[0090] A X90-grade multi-phase structure pipeline steel for straight seam welded pipes, its components and weight percentages are: C: 0.065%, Si: 0.22%, Mn: 1.66%, P: 0.005%, S: 0.0006:%, Nb : 0.072%, Ti: 0.018%, Cu: 0.23%, Cr: 0.23%, Mo: 0.22%, Ni: 0.23%, Al: 0.035%, N: 0.0055%, the rest is Fe and unavoidable impurities; welding cracks Sensitivity coefficient CE Pcm =0.18.

[0091] Follow the steps below to produce:

[0092] 1) Molten iron is desulfurized by KR deep, oxygen-blowing decarburization and dephosphorization in 210-ton converter, Si-Ca treatment, and then cast into slabs, control the end point of molten steel S ≤ 0.0008%, P ≤ 0.010%, protection casting, slab cross-sectional size It is 250×2200mm. Control slab quality center segregation C class 0.5, no intermediate cracks;

[0093] 2) The slab is slowly cooled in the slow cooling pit for 2-3 days;

[0094] 3) The slab is heated, and the heating temperature is controlled at 1160°C to ensure that the slab is supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com