Carbon-based composite fuel cell cathode oxygen reduction catalyst and preparation method thereof

A fuel cell cathode and composite technology, which can be used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, battery electrodes, etc. problems such as transport and ion diffusion properties, to achieve the effect of simple and controllable method, conducive to large-scale production and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

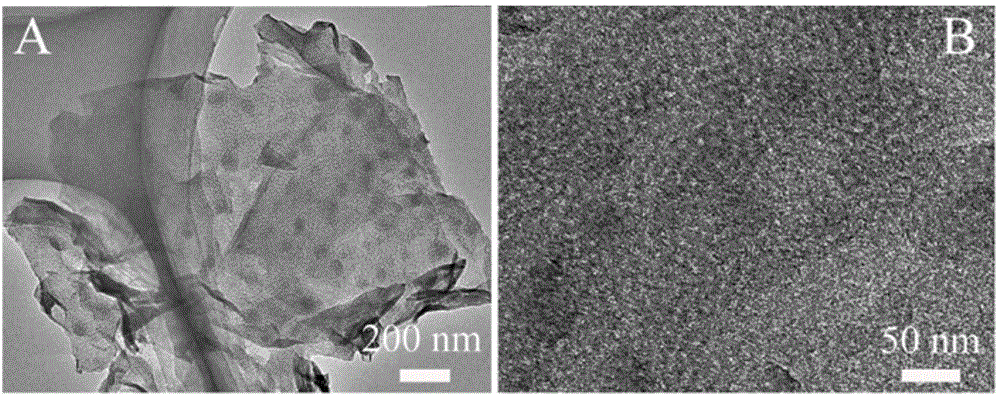

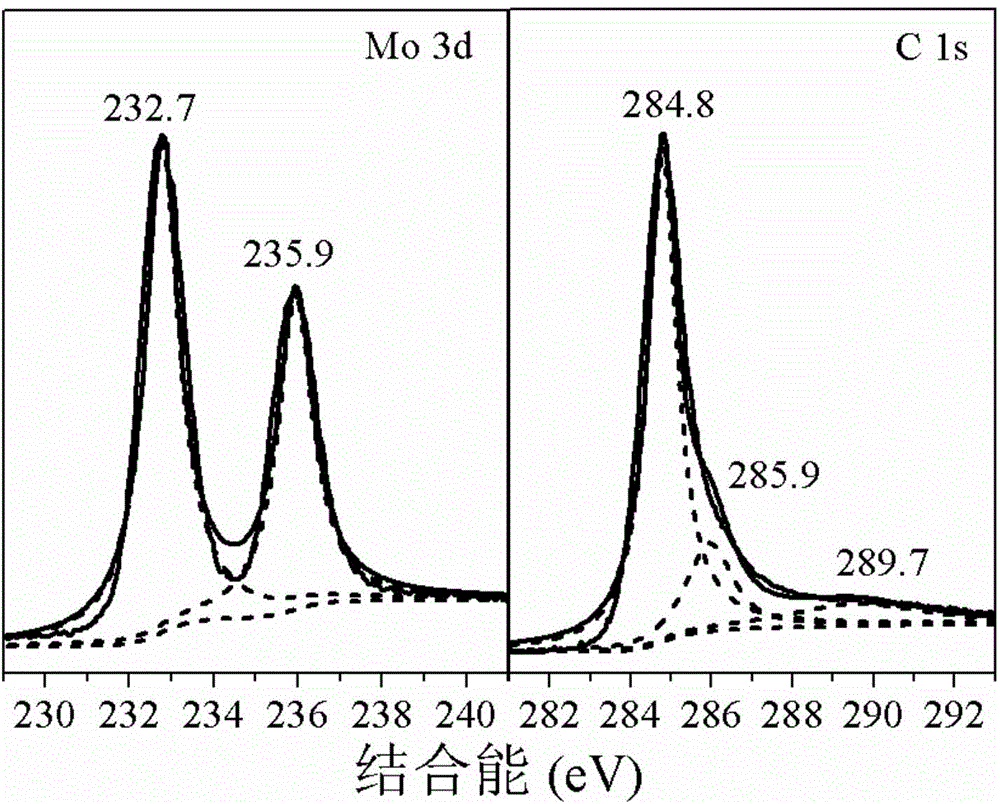

[0034] A method for preparing a carbon-based composite fuel cell cathode oxygen reduction catalyst, specifically comprising the following steps:

[0035](1) Preparation of graphite oxide: graphite oxide is prepared by using natural graphite powder through the improved Hummers method, which is divided into three steps. Step 1: Disperse 3g of graphite powder (325 mesh) in a solution consisting of 12mL of concentrated sulfuric acid, 2.5g of potassium thiosulfate, and 2.5g of phosphorus pentoxide, and reflux and stir in an oil bath at 80°C for 4.5 hours. Then it was naturally cooled to room temperature, and added dropwise to 0.5L deionized water in an ice-water bath (concentrated sulfuric acid exotherms when it meets water), and stirred overnight. Finally, filter through a PTFE filter with a pore size of 0.2 μm to remove excess acid, and dry at room temperature. Step 2: Disperse the above pre-oxidized graphite powder into 150mL of concentrated sulfuric acid, gradually add 15g of ...

Embodiment 2

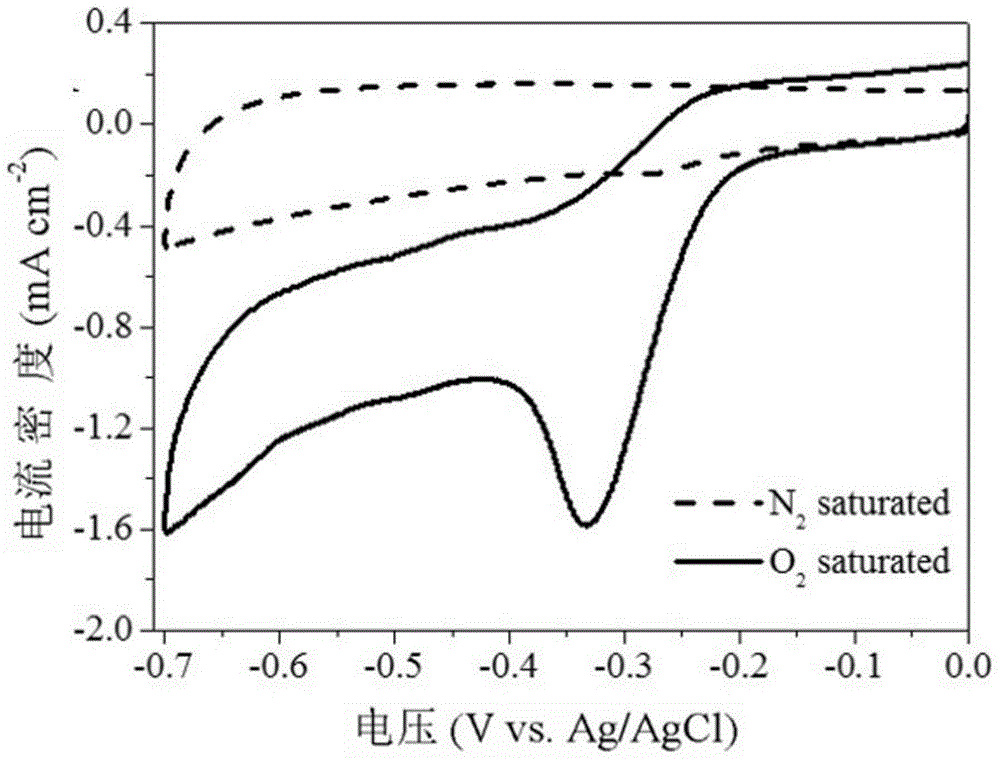

[0046] A kind of preparation of nitrogen-doped mesoporous carbon-graphene composite body, comprises the steps:

[0047] Disperse graphite oxide in deionized water, the mass ratio of graphite oxide to deionized water is 2:1, ultrasonically disperse evenly, then add 10mL ~ 20mL phenolic resin prepolymer, ultrasonically stir to obtain a uniform solution, and then transfer it to In a high-pressure reactor, react at 120°C to 160°C for 10 to 30 hours; after it is naturally cooled to room temperature, wash it with deionized water and ethanol, and obtain a powder solid after suction filtration and drying; put the obtained powder solid in an ammonia atmosphere calcination at 600° C. to 900° C. for 1 to 5 hours to fully nitride it, and obtain a mesoporous carbon-graphene composite doped with nitrogen ions.

[0048] Figure 6 The cyclic voltammetry curves of the nitrogen-doped mesoporous carbon-graphene composite and the mesoporous carbon-graphene composite obtained in this example. in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com