Negative ion-released antibacterial powdery paint

An antibacterial powder and negative ion technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of air pollution accumulation of bacteria and viruses, lack of functionality in surface decoration, gas cannot be diffused and eliminated, and achieve various performances Excellent, good environmental protection performance, long-term effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

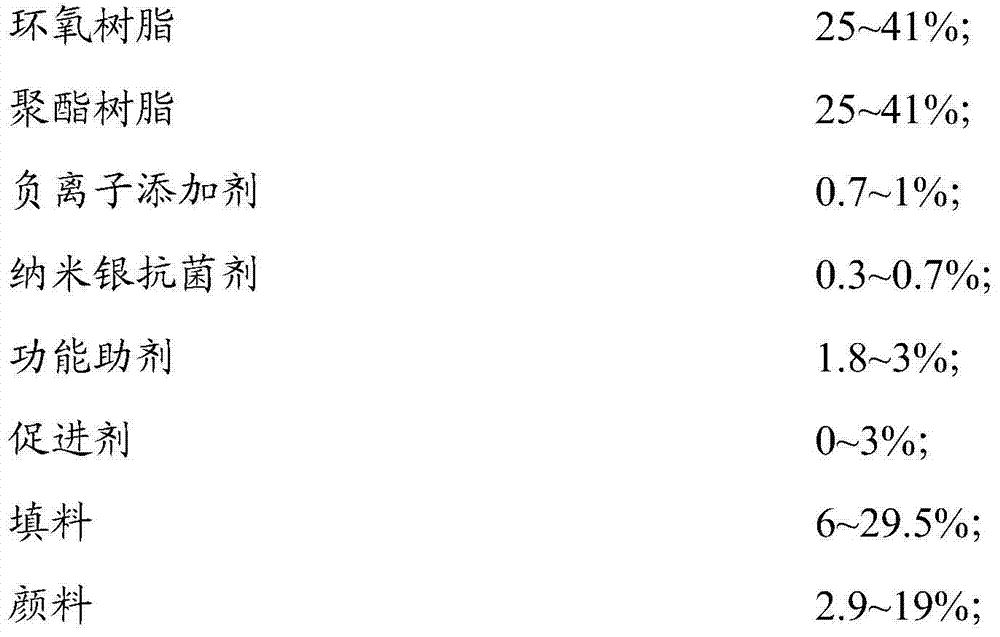

[0057] A negative ion release antibacterial powder coating, which is prepared from the following raw materials in mass percentage:

[0058]

[0059]

[0060] The preparation steps are:

[0061] (1) After the raw materials are weighed according to the above ratio, they are mechanically mixed in a mixing pot and melted and extruded to obtain powder flakes;

[0062] (2) Grinding the powder flakes in an air classifying mill to form powder particles, which are separated by sieving.

[0063] Curing process:

[0064] Surface pretreatment of the workpiece (standard aluminum plate) → spraying negative ion release antibacterial powder coating → heating and leveling at 200°C for 5 minutes → curing at 180°C / 10min or 200°C / 5min → workpiece inspection and storage.

Embodiment 2

[0066] A negative ion release antibacterial powder coating, which is prepared from the following raw materials in mass percentage:

[0067]

[0068] The preparation method is the same as in Example 1.

[0069] Curing process:

[0070] Surface pretreatment of the workpiece (standard aluminum plate) → spraying negative ion release antibacterial powder coating → heating and leveling at 200°C for 5 minutes → curing at 180°C / 10min or 200°C / 5min → workpiece inspection and storage.

Embodiment 3

[0072] A negative ion release antibacterial powder coating, which is prepared from the following raw materials in mass percentage:

[0073]

[0074] The preparation method is the same as in Example 1.

[0075] Curing process:

[0076] Surface pretreatment of the workpiece (standard aluminum plate) → spraying negative ion release antibacterial powder coating → heating and leveling at 200°C for 5 minutes → curing at 180°C / 10min or 200°C / 5min → workpiece inspection and storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com