Method for preparing Si3N4/BAS foamed ceramic material

A foamed ceramic and slurry technology, which is applied in the field of porous ceramic materials, can solve the problems of low strength of foamed ceramic body, easy collapse of the body, poor formability of the foamed body, etc. Highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

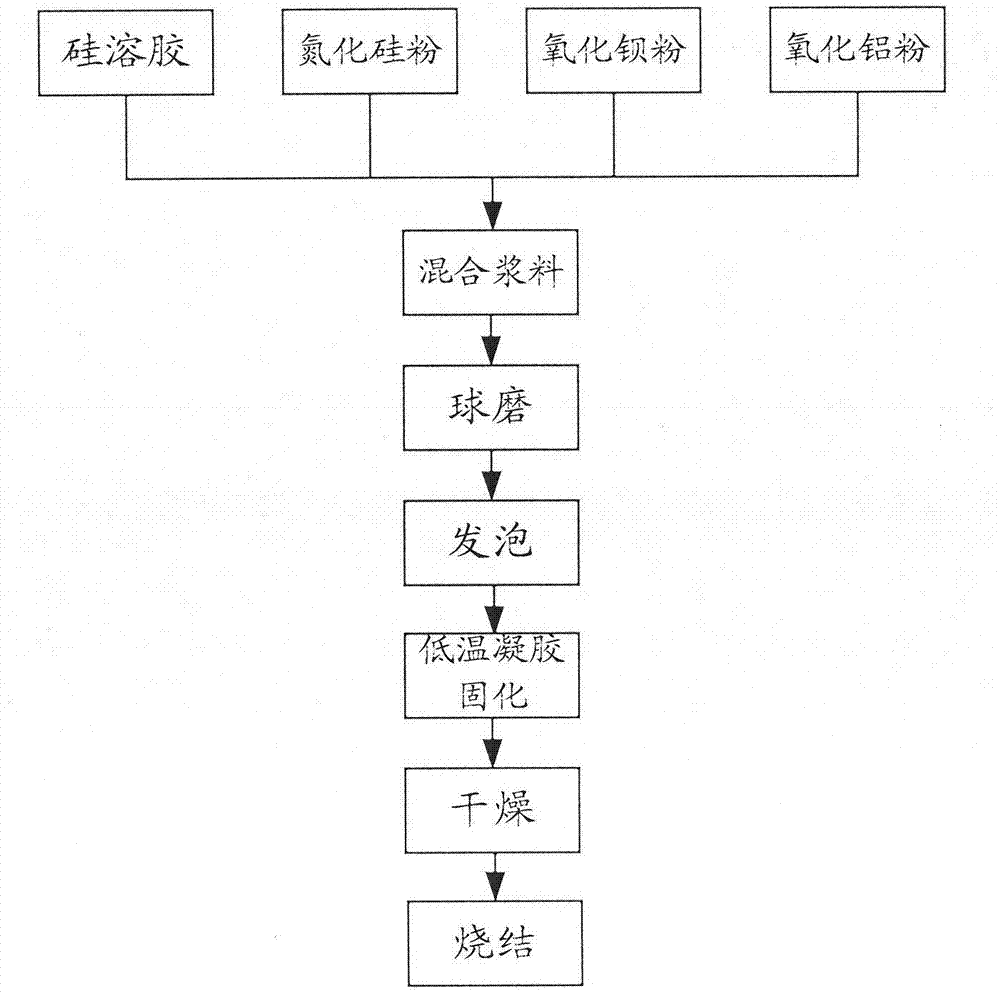

Method used

Image

Examples

Embodiment 1

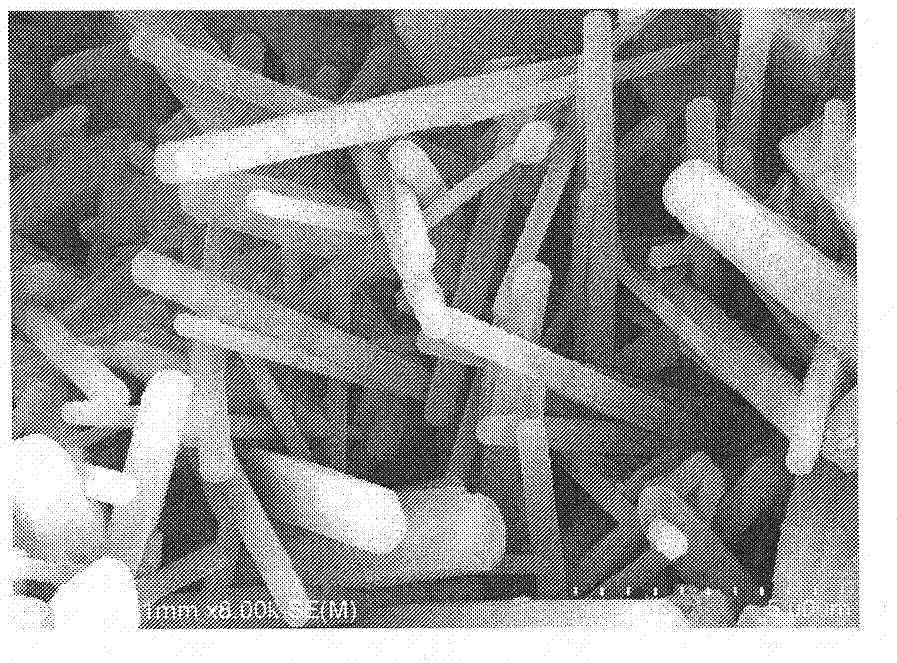

[0041] Add silicon nitride powder, barium oxide powder, aluminum oxide powder and a small amount of tetramethylammonium hydroxide dispersant to the silica sol to prepare slurry, wherein the addition of barium oxide and aluminum oxide is based on the mass of silicon dioxide in the silica sol As a benchmark, according to the stoichiometric ratio BaO-Al 2 o 3 -2SiO2 2 Add, the total solid phase (sum of silicon dioxide quality in silicon nitride powder, barium oxide powder, aluminum oxide powder and silica sol) content in the slurry is 55%, and the mass ratio of silicon nitride powder and BAS is 80 : 20; after ball milling mixing 5h in the high-speed ball mill, add 2% (taking solid phase gross mass as benchmark) foaming agent in the slurry, high-speed mechanical stirring 30min is fully foamed, until forming uniform and stable foam, will The foam slurry was injected into the mold, and then kept in liquid nitrogen for 30 minutes, and the sample after demoulding was thoroughly drie...

Embodiment 2~5

[0044] Add silicon nitride powder (Tsinghua Unigroup, Beijing), barium oxide powder, and alumina powder to the silica sol, wherein the addition of barium oxide and alumina is based on the quality of silicon dioxide in the silica sol, according to the stoichiometric ratio BaO-Al 2 o 3 -2SiO2 2 Add, the total solid phase (sum of silicon dioxide quality in silicon nitride powder, barium oxide powder, aluminum oxide powder and silica sol) content in the slurry is respectively 65%, 50%, 45% and 40%, nitrogen The mass ratio of silica powder and BAS is 90:10; then add 1% dispersant (tetramethylammonium hydroxide) and 1% sodium carboxymethyl cellulose, and use a high-speed ball mill to mix the mixture for 5 hours. After the slurry is degassed Inject into the mold, and then keep warm in liquid nitrogen for 20 minutes to fully solidify the slurry and demould. After freezing and demolding, the sample is heated to 80°C and kept warm to dry the sample thoroughly; after the sample is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com