A kind of microemulsion synthetic method of mesoporous β tricalcium phosphate

A technology of tricalcium phosphate and synthesis method, which is applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of mesoporous β-TCP crystal habit, synthesis difficulties, etc., and achieves continuously adjustable pore size and repeatability. Good, narrow pore size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

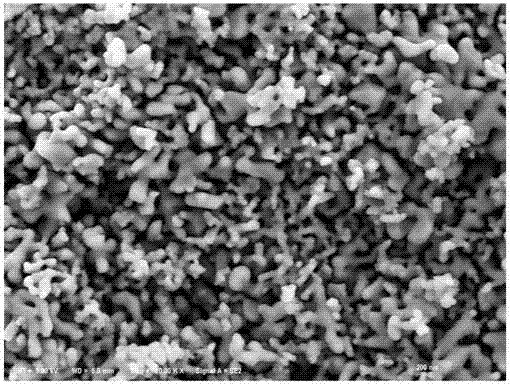

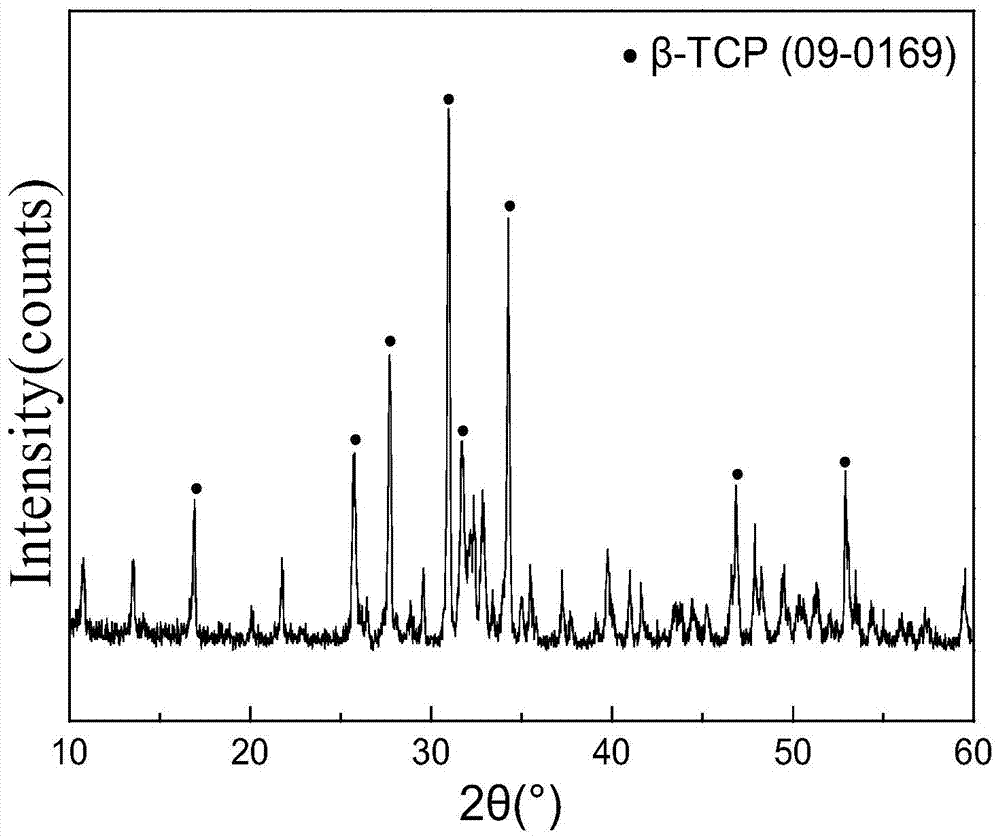

[0024] Add surfactant CTAB, oil phase cyclohexane and cosurfactant 1-octanol to 50mL water, wherein the concentration of surfactant is 100g / L, the concentration of oil phase is 250mL / L, and the concentration of cosurfactant is 250mL / L L, stirred at 37°C for 50min to obtain a microemulsion, and then 20mL of 0.3mol / L Ca(NO 3 ) 2 4H 2 The O solution was slowly added dropwise into the microemulsion, and magnetic stirring was continued for 30 min. Add 0.3mol / L (NH 4 ) 2 HPO 4 solution, and make the element Ca / P (molar ratio) = 1.5, use NH 3 ·H 2 The pH of the O solution was adjusted to 8.0, and the magnetic stirring was continued for 24 hours, then left to age at room temperature for 24 hours, centrifuged at 10,000 rpm for 2 minutes, and the obtained precipitate was washed three times with water and then three times with alcohol. Finally, the precipitate was dried in a drying oven at 80°C for 24h, then heated to 800°C at a rate of 5°C / min at room temperature, and heat-treate...

Embodiment 2

[0027] Add surfactant sodium dodecylbenzenesulfonate, oil phase n-octane and co-surfactant n-propanol to 100mL water, wherein the concentration of surfactant is 25g / L, and the concentration of oil phase is 50mL / L, to help the surface The active agent concentration is 50mL / L, stirred at 90°C for 35min to obtain a microemulsion, and then 60mL of 0.9mol / L CaCO 3 The solution was slowly added dropwise into the microemulsion, and magnetic stirring was continued for 40 min. Then slowly drop 0.9mol / L H at a rate of 0.6mL per minute 3 PO 4 solution, and make the element Ca / P (molar ratio) = 1.5, use NH 3 ·H 2The pH of the O solution was adjusted to 9.0, and magnetic stirring was continued for 2 hours, then left to age at room temperature for 12 hours, centrifuged at 10,000 rpm for 4 minutes, and the obtained precipitate was washed twice with water and then twice with alcohol. Finally, the precipitate was dried in a drying oven at 120°C for 12 hours, then heated to 950°C at a rate ...

Embodiment 3

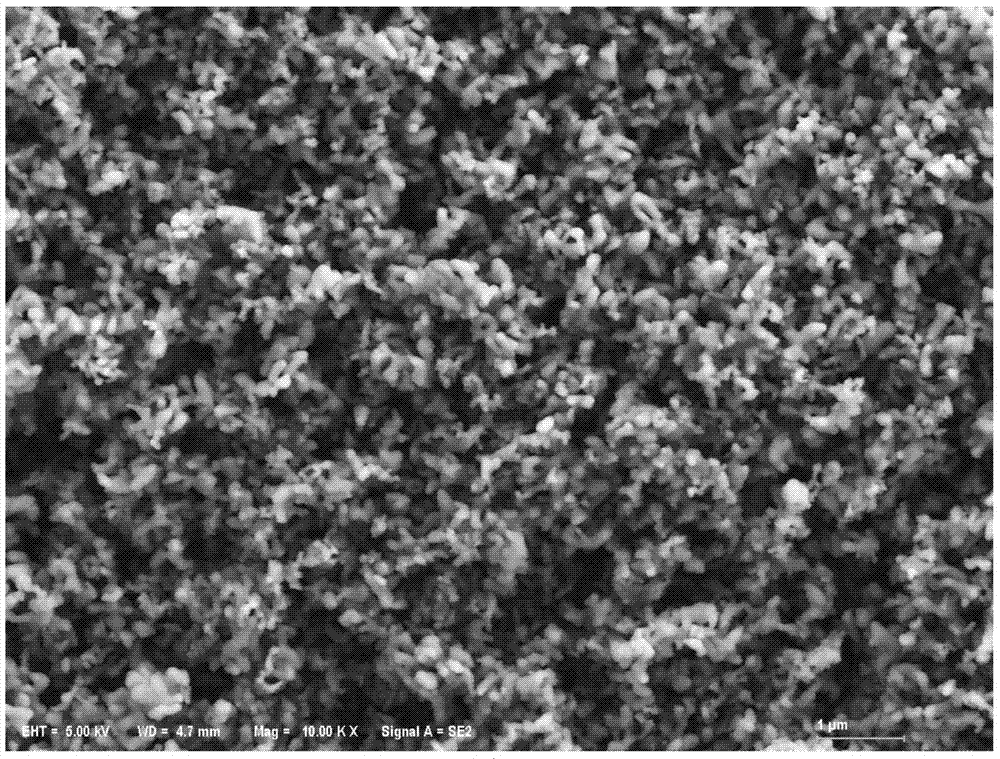

[0029] Add surfactant polyoxyethylene-polyoxypropylene-polyoxyethylene, oil phase n-hexane and co-surfactant n-butanol to 40mL water, wherein the concentration of surfactant is 50g / L, and the concentration of oil phase is 100mL / L, The co-surfactant concentration is 100mL / L, stirred at 25°C for 60min to obtain a microemulsion, and then 25mL of 0.5mol / L CaCl 2 The solution was slowly added dropwise into the microemulsion, and magnetic stirring was continued for 30 minutes. Slowly add 0.5 mol / L of NH at a rate of 0.2 mL per minute 4 h 2 PO 4 solution, and make the element Ca / P (molar ratio) = 1.5, use NH 3 ·H 2 The pH of the O solution was adjusted to 6.0, and magnetic stirring was continued for 12 hours, then left to age at room temperature for 24 hours, and centrifuged at 9500 rpm for 3 minutes to obtain a precipitate, which was washed three times with water and then washed once with alcohol. Finally, the precipitate was dried in a drying oven at 80°C for 22 hours, then he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com