Manufacturing method and in-situ characterizing method for graphene field effect transistor free of residual optical photoresist

A graphene surface and graphene technology, applied in the field of in-situ characterization of graphene FET, can solve problems such as difficult to meet actual needs, achieve high carrier mobility and device performance, reduce doping degree, and reduce device performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

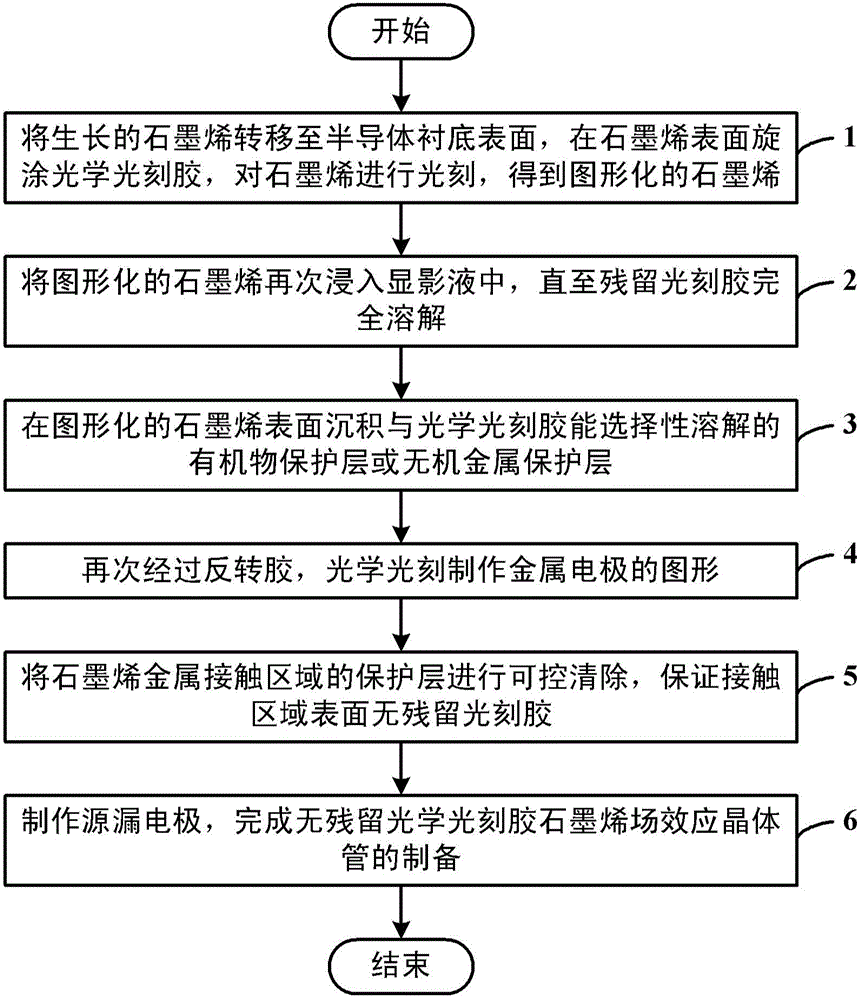

[0054] based on figure 1 The flow chart of the method for preparing no-residue optical photoresist graphene field-effect transistor shown, figure 2 shows that in accordance with figure 1 Schematic diagram of in-situ characterization of the prepared residue-free graphene field-effect transistor, the in-situ characterization method includes:

[0055] Step 1: Using EFM or conductive AFM to characterize and study the change of carrier mobility in graphene in the device within the range of the applied electric field on a microscopic scale; wherein, the change range of the applied electric field is -3~+3V.

[0056] Step 2: On the basis of EFM or conductive AFM characterization, use the tip of AFM as a test probe, use the oxide layer of the substrate itself as a medium, and monitor the gate control characteristics of graphene in real time for in-situ characterization; among them, the substrate The Si substrate is selected, and the oxide layer of the substrate itself is SiO with a ...

Embodiment 1

[0060] The preparation method of the graphene FET without residual optical photoresist comprises the following steps, specifically comprising:

[0061] 1) Transfer the single-layer uniform graphene grown on the surface of copper foil by CVD to SiO with a 330nm insulating layer 2 / Si substrate surface. Spin-coat a layer of 9912 positive photoresist with a thickness of 1.4 μm on the surface of the substrate spread with graphene, after exposure (light intensity 5, time 15 seconds), development (40 seconds), primer, and acetone to remove the glue , patterning the active region of graphene;

[0062] 2) Immerse the patterned graphene in the positive resist developer again, let it stand for 10 seconds, and dry it with nitrogen;

[0063] 3) On the patterned graphene surface, deposit 10nm metal nickel as a protective layer of graphene by electron beam evaporation technology;

[0064] 4) Spin-coat a layer of AZ5214 reverse glue with a thickness of 1.4 μm on the surface of the protect...

Embodiment 2

[0073] The preparation scheme of graphene FET without residual optical photoresist includes the following steps, specifically including:

[0074] 1) A single layer of uniform graphene grown on the surface of copper foil by CVD is transferred to SiO with a 300nm insulating layer 2 / Si substrate surface. Spin-coat a layer of 9920 positive photoresist with a thickness of 1.4 μm on the surface of the substrate spread with graphene, after exposure (light intensity 5, time 15 seconds), development (40 seconds), Matrix primer, acetone to remove Glue to pattern the active area of graphene;

[0075] 2) Immerse the patterned graphene in the positive resist developer again, let it stand for 10 seconds, and dry it with nitrogen;

[0076] 3) on the patterned graphene surface, adopt the method for spin-coating to deposit 20nm α-methyl polystyrene as the protective layer of graphene;

[0077] 4) Spin-coat a layer of AZ5214 reverse glue with a thickness of 1.4 μm on the surface of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com