Composite matrix material for grinding wheel, preparation method and grinding wheel

A technology of base materials and grinding wheels, which is applied in the field of grinding wheels, can solve the problems of low bonding strength, self-consumption, and damage to processed workpieces, and achieve the effects of not easy to detach rings or blocks, reduce the cost of the base, and achieve high interface bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The composite base material for the grinding wheel of the present embodiment comprises the following components in mass percent:

[0046]

[0047] The preparation method of the composite base material for the emery wheel of the present embodiment comprises the following steps:

[0048] 1) Take γ-aminopropyltriethoxysilane (KH550), dilute it with water according to the dilution ratio of 1:100, spray it on the surface of brown corundum dust in mist form, mix it evenly, and place it in a blast oven at 80°C Dry for 12 hours, sieve to obtain mixed powder A;

[0049] 2) Take the thermosetting polyimide resin powder, copper powder and the mixed powder A obtained in step 1) in the formula amount, put them in a mixer, mix and disperse for 2 hours until they are evenly mixed, and then get the mixed powder B;

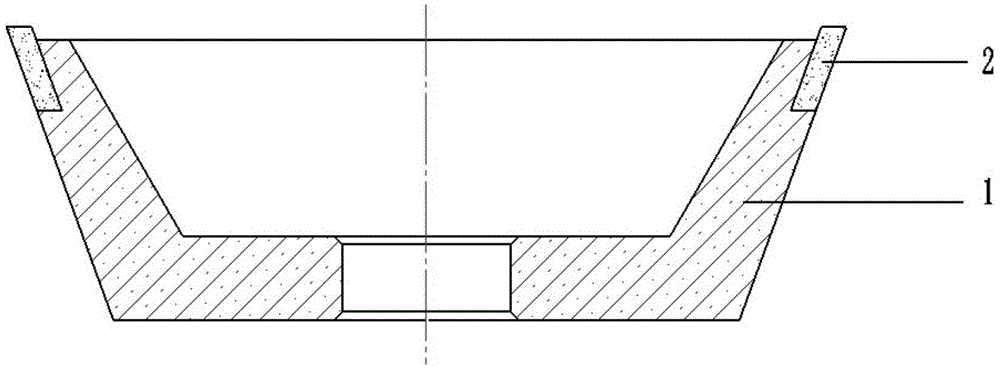

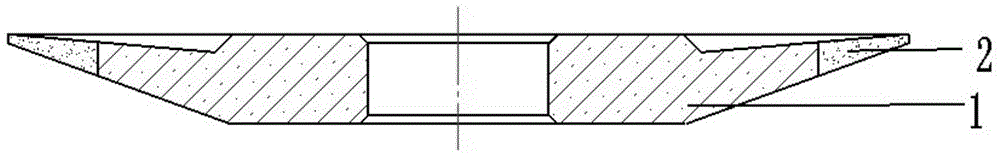

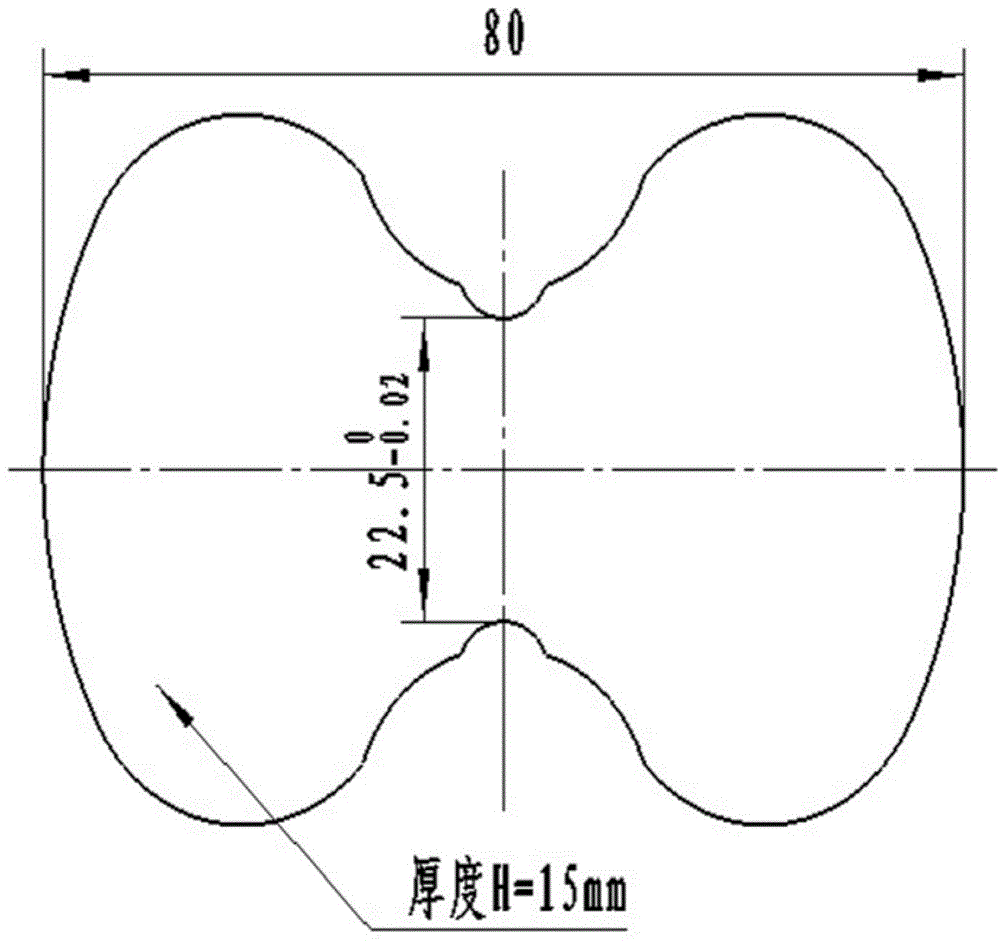

[0050] 3) Select the matrix mold according to the shape and specification of the grinding wheel, put the mixed powder B obtained in step 2) into the mold, scrape it flat,...

Embodiment 2

[0058] The composite base material for the grinding wheel of the present embodiment comprises the following components in mass percent:

[0059]

[0060] The preparation method of the composite base material for the emery wheel of the present embodiment comprises the following steps:

[0061] 1) Take γ-(2,3-glycidyloxypropoxy)propyltrimethoxysilane (KH560), dilute it with water according to the dilution ratio of 1:120, spray it on the surface of brown corundum dust in mist form, and mix it evenly. Dry in a blast oven at 100°C for 8 hours, and sieve to obtain mixed powder A;

[0062] 2) Take the thermosetting polyimide resin powder, copper powder and the mixed powder A obtained in step 1) in the formula amount, put them in a mixer, mix and disperse for 2 hours until they are evenly mixed, and then get the mixed powder B;

[0063] 3) Select the matrix mold according to the shape and specification of the grinding wheel, put the mixed powder B obtained in step 2) into the mold...

Embodiment 3

[0071] The composite base material for the grinding wheel of the present embodiment comprises the following components in mass percent:

[0072]

[0073] The preparation method of the composite base material for the emery wheel of the present embodiment comprises the following steps:

[0074] 1) Take γ-(methacryloyloxy)propyltrimethoxysilane (KH570), dilute it with water according to the dilution ratio of 1:150, spray it on the surface of brown corundum dust in the form of mist, mix it evenly, and place it at 90 Dry in a blast oven at ℃ for 10 hours, and sieve to obtain mixed powder A;

[0075] 2) Take the thermosetting polyimide resin powder, iron powder and the mixed powder A obtained in step 1) in the formula amount, put them in a mixer, mix and disperse for 2 hours until they are evenly mixed, and then get the mixed powder B;

[0076] 3) Select the matrix mold according to the shape and specification of the grinding wheel, put the mixed powder B obtained in step 2) int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com