Modified cellulose material for adsorbing heavy metal ions and organic pollutants and preparation method thereof

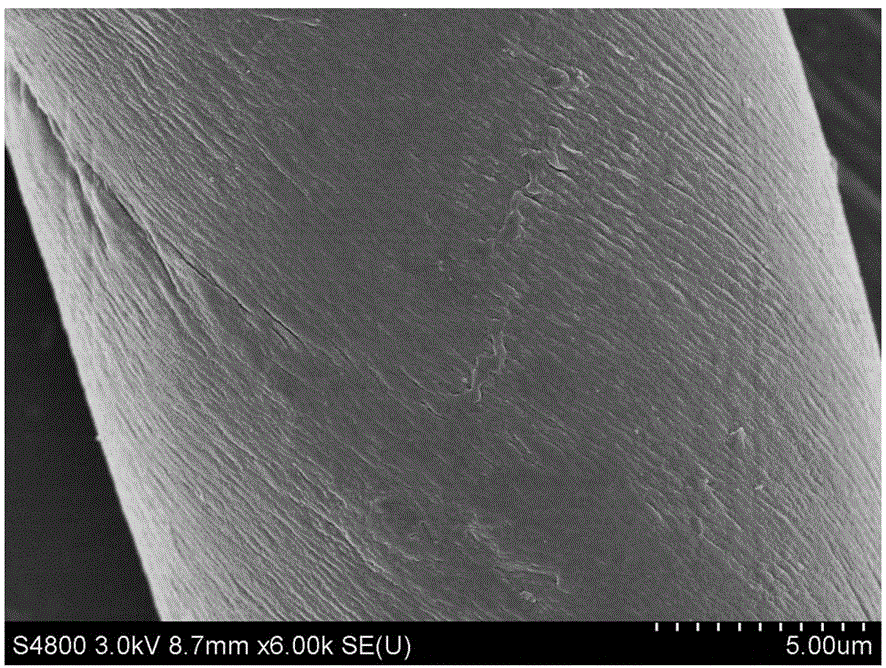

A technology for organic pollutants and heavy metal adsorption, which is applied to amidoxime-hydroxymidoxime modified cellulose materials and preparation, modified cellulose materials and preparation fields, and achieves the effects of strong adsorption capacity, easy mass production and rough surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

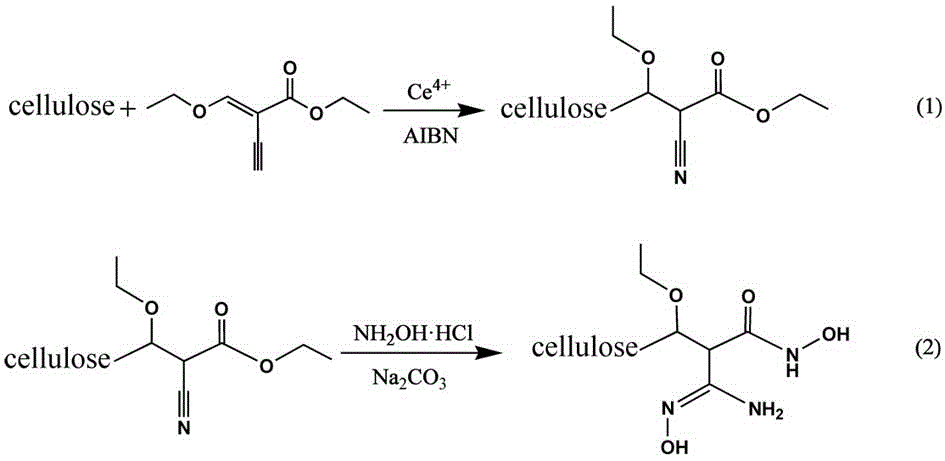

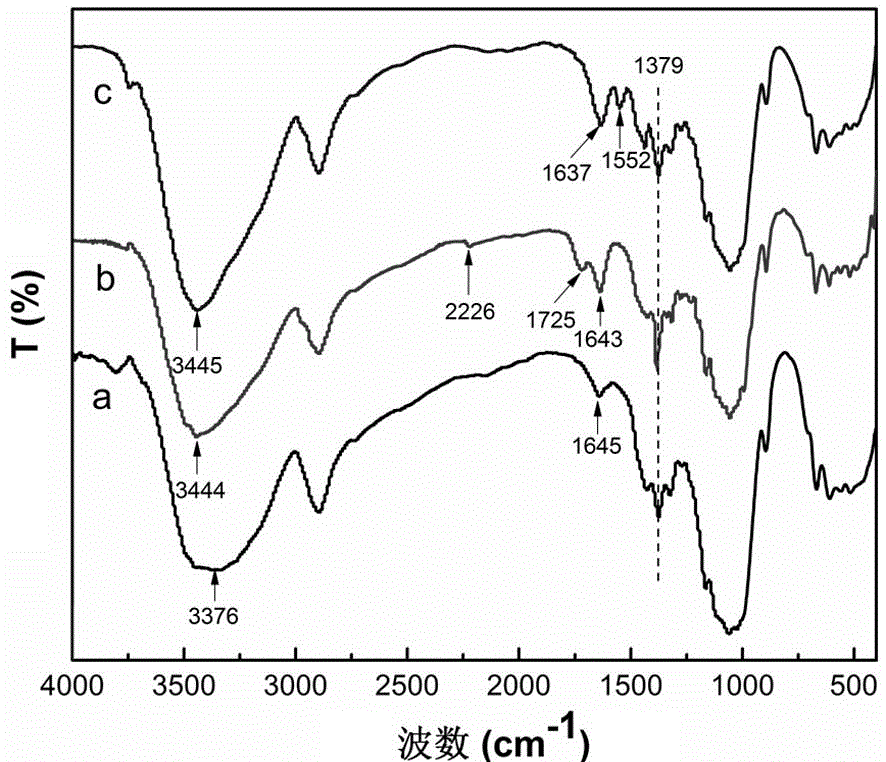

[0026] See attached figure 1 , is the flow chart of the preparation of the modified cotton fiber material in this embodiment. Reaction (1) is under the action of composite initiator cerium ammonium nitrate and azobisisobutyronitrile, 2-cyano-3-ethoxyethyl acrylate is grafted onto the alkalized cotton fiber; reaction (2) is the The graft copolymer undergoes amidoximation transformation under the action of hydroxylamine hydrochloride and sodium carbonate, the cyano group is converted into amidoxime group, and the ester bond is converted into hydroxylamine oxime group, so the finished product contains both amidoxime group and Modified cotton fiber material containing hydroxamidoxime groups. The concrete steps of preparation method are as follows:

[0027] (1) Cotton fiber alkalization: Weigh 5g of cotton fiber, put it in 250mL NaOH solution with a concentration of 1wt%, and scorch at 85°C for 120min, take out the filtered water and transfer it to 150mL NaOH solution with a conc...

Embodiment 2

[0034] (1) Alkalization of viscose fiber: Weigh 5g of viscose fiber, put it in 100mL of NaOH solution with a concentration of 4wt%, simmer at 90°C for 90min, take out the filtered water and transfer it to 250mL of NaOH solution with a concentration of 12wt%. Stir at 25°C for 90 minutes, and the product is filtered, washed with deionized water, and dried to obtain alkalized viscose fiber.

[0035] (2) Graft copolymerization: Take 2g of the above-mentioned alkalized viscose fiber and place it in a four-necked flask filled with 60mL of isopropanol solution. - Ethoxy ethyl acrylate magnetically stirred for 15min, then added 0.01g of cerium ammonium nitrate and 0.008g of azobisisobutyronitrile into the above reaction solution, continued to stir and react for 2h, took out and filtered, washed with methanol, deionized water, 50 Dry at ℃ to obtain graft copolymerized viscose fiber.

[0036] (3) Ammoximation: Dissolve 4g of hydroxylamine hydrochloride and 2.3g of sodium hydroxide in m...

Embodiment 3

[0038] (1) Alkalinization of microcrystalline cellulose: Weigh 5g of microcrystalline cellulose, put it in 150mL of NaOH solution with a concentration of 2.5wt%, scorch at 100°C for 60min, take out the filtered water and transfer to 100mL of NaOH with a concentration of 25wt% The solution was stirred at 30°C for 75 minutes, and the product was filtered, washed with deionized water, and dried to obtain alkalized microcrystalline cellulose.

[0039] (2) Graft copolymerization: Take 2g of the above-mentioned alkalized microcrystalline cellulose and place it in a four-necked flask filled with 80mL of methanol solution. Ethoxyethyl acrylate was magnetically stirred for 45 minutes, then 0.05g of cerium ammonium nitrate and 0.05g of azobisisobutyronitrile were added to the above reaction liquid, and the stirring reaction was continued for 6 hours, and then washed with methanol, deionized water, and 50°C drying to obtain graft copolymerized microcrystalline cellulose.

[0040] (3) Am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com