Spraying preparation method for Cu/Mo/Cu composite thin plate

A composite thin plate and spraying device technology, which is applied in the direction of coating, metal material coating process, heating inorganic powder coating, etc., can solve the problems of complex rolling process, large one-time investment, poor controllability, etc., to achieve The effect of flexible and adjustable thickness, controllable quality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

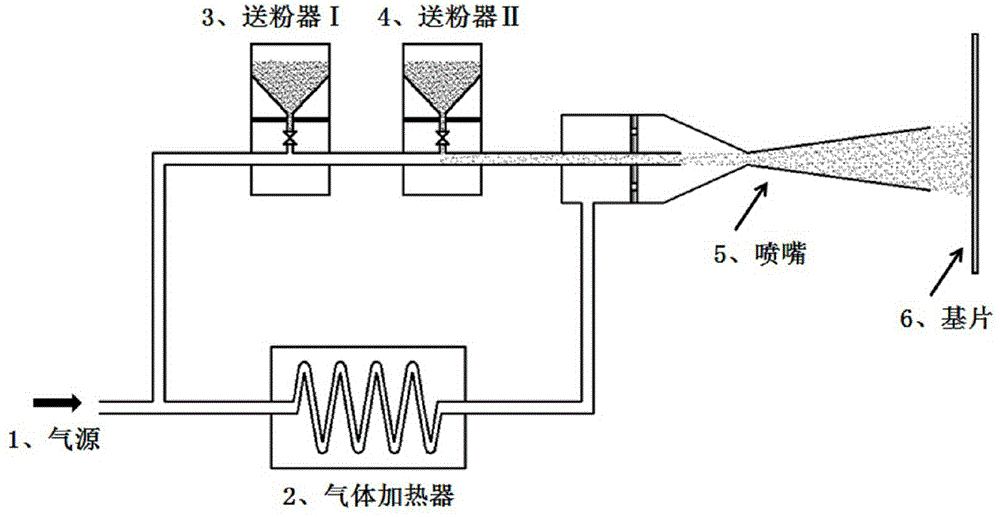

Method used

Image

Examples

Embodiment 1

[0038] The spraying preparation method of Cu / Mo / Cu composite sheet of the present invention, the detailed steps of this preparation method are as follows:

[0039] a. Substrate pretreatment:

[0040] Using a molybdenum Mo sheet with a thickness of 0.3mm, a size of 0.3mm×100mm×100mm, and a purity of ≥98% as the substrate, the molybdenum sheet is first cleaned with lye with a mass concentration of 8% and a temperature of 70°C for 7 minutes to remove oil stains Then use dilute hydrochloric acid with a mass concentration of 6% to clean for 5 minutes to remove the thin oxide layer on the surface; rinse with water after cleaning with dilute hydrochloric acid; use absolute ethanol to perform ultrasonic cleaning after rinsing, and dry it for use after cleaning;

[0041] b. Selection of spraying powder:

[0042] Ni powder with a particle size of 0.08-0.8 μm and a purity of ≥99.5% is selected for the spray transition layer, and Cu powder with a particle size of 1.5-20 μm and a purity o...

Embodiment 2

[0052] The spraying preparation method of Cu / Mo / Cu composite sheet of the present invention, the detailed steps of this preparation method are as follows:

[0053] a. Substrate pretreatment:

[0054] Using a molybdenum Mo sheet with a thickness of 0.6mm, a size of 0.6mm×100mm×100mm, and a purity of ≥98% as the substrate, the molybdenum sheet is first cleaned with lye with a mass concentration of 10% and a temperature of 60°C for 5 minutes to remove oil stains ; then use mass concentration of 4% dilute hydrochloric acid to clean for 8 minutes to remove the surface oxide thin layer; rinse with water after dilute hydrochloric acid cleaning; use absolute ethanol to carry out ultrasonic cleaning after rinsing, dry after cleaning for use;

[0055] b. Selection of spraying powder:

[0056] Ni powder with a particle size of 0.08-0.8 μm and a purity of ≥99.5% is selected for the spray transition layer, and Cu powder with a particle size of 1.5-20 μm and a purity of ≥99.5% is selected ...

Embodiment 3

[0066] The spraying preparation method of Cu / Mo / Cu composite sheet of the present invention, the detailed steps of this preparation method are as follows:

[0067] a. Substrate pretreatment:

[0068] Using a molybdenum Mo sheet with a thickness of 0.8mm, a size of 0.8mm×100mm×100mm, and a purity of ≥98% as the substrate, first clean the molybdenum sheet with lye with a mass concentration of 5% and a temperature of 80°C for 10 minutes to remove oil stains Then use dilute hydrochloric acid with a mass concentration of 8% to clean for 3 minutes to remove the thin oxide layer on the surface; rinse with water after cleaning with dilute hydrochloric acid; use absolute ethanol to perform ultrasonic cleaning after rinsing, and dry it for use after cleaning;

[0069] b. Selection of spraying powder:

[0070] Ni powder with a particle size of 0.08-0.8 μm and a purity of ≥99.5% is selected for the spray transition layer, and Cu powder with a particle size of 1.5-20 μm and a purity of ≥9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com