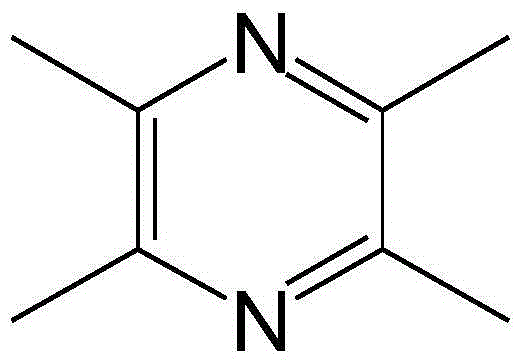

Preparation method of ligustrazine

A technology of ligustrazine and solution, applied in the field of compound preparation, can solve the problems of low yield, long reaction time, large energy consumption, etc., and achieve the effects of strong stability, reduction of processing steps and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

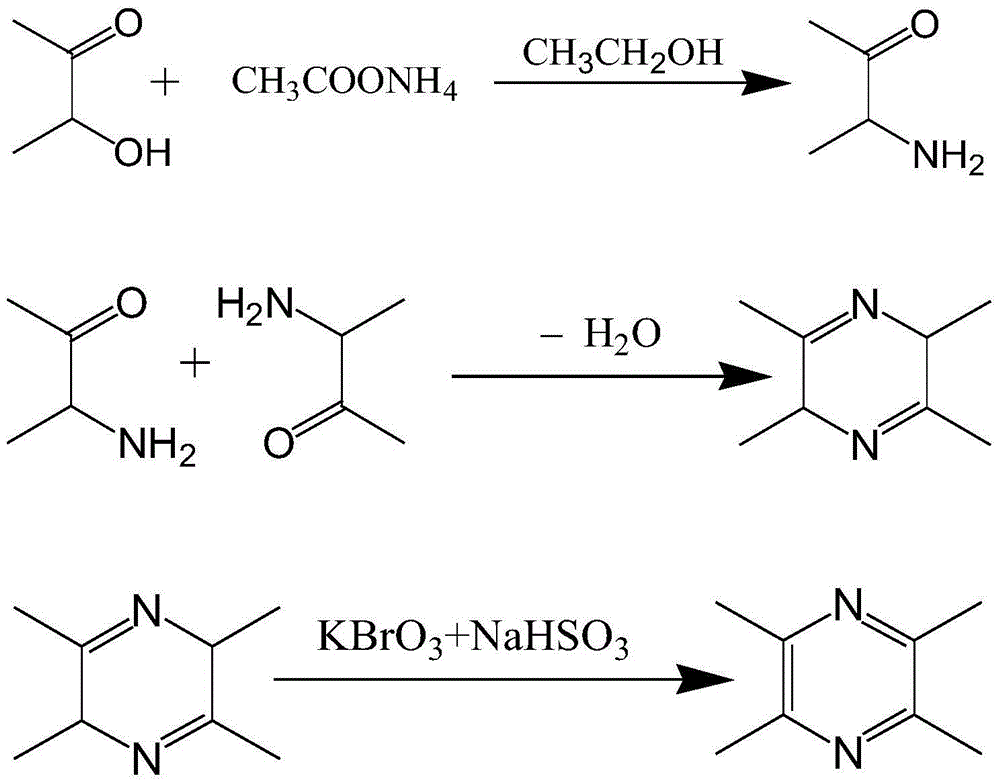

[0042] The preparation method of a kind of ligustrazine proposed by the present invention comprises the following steps:

[0043]S1, 21 parts of 3-hydroxy-2-butanone and 19 parts of ammonium acetate are added to the reaction vessel as main ingredients by weight, after adding dehydrated alcohol, feed nitrogen, and the temperature that the water bath is heated to the main ingredient is 89 ° C After stirring for 5h, stop feeding nitrogen gas until the temperature is lowered to room temperature, wherein the volume-to-weight ratio (ml:g) of absolute ethanol and 3-hydroxy-2-butanone is 3.2:1;

[0044] S2, add aromatization catalyst and glacial acetic acid in reaction vessel and stir for 1h, then filter to obtain filtrate A, wherein the weight ratio of aromatization catalyst and main material is 38.5:38, and aromatization catalyst is composed of potassium bromate and hydrogen sulfite The molar ratio of sodium is 1.2:0.9, and the volume-to-weight ratio of glacial acetic acid and potas...

Embodiment 2

[0051] The preparation method of a kind of ligustrazine proposed by the present invention comprises the following steps:

[0052] S1, add 19.7 parts of 3-hydroxy-2-butanone and 20.2 parts of ammonium acetate as main ingredients into the reaction vessel by weight, add dehydrated ethanol, feed nitrogen, and heat the water bath to the temperature of the main ingredients to be 80 ° C After stirring for 7h, stop feeding nitrogen gas until the temperature is lowered to room temperature, wherein the volume-to-weight ratio (ml:g) of absolute ethanol and 3-hydroxy-2-butanone is 2.9:1;

[0053] S2, add aromatization catalyst and glacial acetic acid to the reaction vessel and stir for 1.7h, then filter to obtain filtrate A, wherein the weight ratio of aromatization catalyst and main material is 36.5:41, and aromatization catalyst is composed of potassium bromate and sulfurous acid The molar ratio of sodium hydrogen is 0.9:1.2, and the volume-to-weight ratio of glacial acetic acid and pot...

Embodiment 3

[0060] The preparation method of a kind of ligustrazine proposed by the present invention comprises the following steps:

[0061] S1, add 20.3 parts of 3-hydroxy-2-butanone and 19.5 parts of ammonium acetate as main ingredients to the reaction vessel by weight, add dehydrated alcohol, feed nitrogen, and heat the water bath to the temperature of the main ingredients to be 82 ° C After stirring for 6h, stop feeding nitrogen gas until the temperature drops to room temperature, wherein the volume-to-weight ratio (ml:g) of absolute ethanol and 3-hydroxy-2-butanone is 3.1:1;

[0062] S2, add aromatization catalyst and glacial acetic acid in reaction vessel and stir for 2h, then filter to obtain filtrate A, wherein the weight ratio of aromatization catalyst and main material is 35.5:42, and aromatization catalyst is composed of potassium bromate and hydrogen sulfite The molar ratio of sodium is 0.8:1.3, and the volume-to-weight ratio of glacial acetic acid and potassium bromate is (m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com