Surface treatment method for rare earth magnesium alloy product

A technology of surface treatment and surface treatment liquid, applied in the direction of anodization, etc., can solve the problems of unstable surface treatment liquid, unstable performance of surface treatment liquid, production and application constraints of surface treatment liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

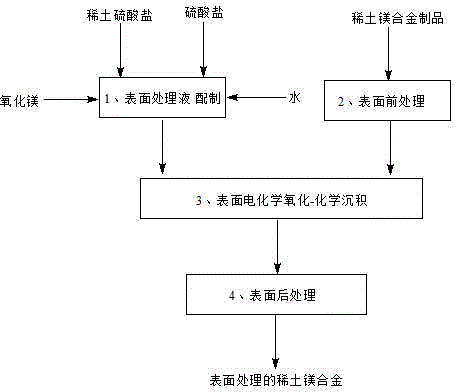

Method used

Image

Examples

Embodiment 1

[0067] A method for surface treatment of Mg-La rare earth magnesium alloy products, comprising the steps of:

[0068] (1) Preparation of surface treatment solution: There are many factors that affect the surface film properties of rare earth magnesium alloys. The film forming time and so on have an influence on the properties of the obtained surface film. Among them, the composition and concentration of the surface treatment solution are the most important factors affecting the composition and performance of the rare earth magnesium alloy surface film. The traditionally used electrochemical oxidation deposition coupling technology for magnesium alloys contains chromium, fluorine, and cyanide plasma, which seriously endanger human health and the ecological environment, and restrict the production and application of surface treatment fluids. Therefore, in the present embodiment, in a stirred tank, water and sulphate are cerium (Ce) and the concentration of rare earth ions is fo...

Embodiment 2

[0073] A method for surface treatment of Mg-Ce rare earth magnesium alloy products, comprising the steps of:

[0074] (1) Preparation of surface treatment solution: There are many factors that affect the surface film properties of rare earth magnesium alloys. The film forming time and so on have an influence on the properties of the obtained surface film. Among them, the composition and concentration of the surface treatment solution are the most important factors affecting the composition and performance of the rare earth magnesium alloy surface film. The traditionally used electrochemical oxidation deposition coupling technology for magnesium alloys contains chromium, fluorine, and cyanide plasma, which seriously endanger human health and the ecological environment, and restrict the production and application of surface treatment fluids. Therefore, the present invention is in stirred tank, and water, sulfate are the rare earth sulfate of cerium (Ce) and lanthanum (La), and ...

Embodiment 3

[0079] A method for surface treatment of Mg-Sm rare earth magnesium alloy products, comprising the steps of:

[0080] (1) Preparation of surface treatment solution: There are many factors that affect the surface film properties of rare earth magnesium alloys. The film forming time and so on have an influence on the properties of the obtained surface film. Among them, the composition and concentration of the surface treatment solution are the most important factors affecting the composition and performance of the rare earth magnesium alloy surface film. The traditionally used electrochemical oxidation deposition coupling technology for magnesium alloys contains chromium, fluorine, and cyanide plasma, which seriously endanger human health and the ecological environment, and restrict the production and application of surface treatment fluids. Therefore, the present invention is in stirred tank, and water, vitriol are the rare earth vitriol that forms in cerium (Ce) and yttrium (Y)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com