A method for producing metal aluminum or aluminum-magnesium alloy with low-grade bauxite

A low-grade bauxite, aluminum-magnesium alloy technology, applied in the direction of improving process efficiency, can solve the problems of not being industrialized, easy to generate dendrites, low electrolysis temperature, etc., to solve the problem of electrolysis to generate dendrites, equipment Easy, low electrolysis temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

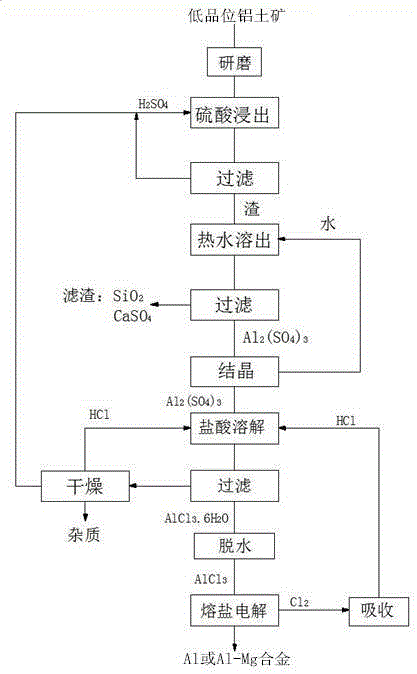

Image

Examples

Embodiment 1

[0031] (1) Acid leaching of low-grade bauxite to produce aluminum chloride: Grind the ore sample 1 shown in Table 1 to 100-200 μm, mix it with sulfuric acid at a mass ratio of 1:3, filter it, and react at 100°C 3h, add 3 times the mass of water to the filter residue, boil and dissolve at 50°C for 60 minutes, dissolve the reactant, filter to remove the residue, and obtain an aluminum sulfate solution, evaporate and crystallize the aluminum sulfate solution, and mix it with hydrochloric acid with a mass concentration of 38%. , and then HCl gas is introduced to precipitate AlCl 3 ·6H 2 O crystals, dried and dehydrated at 110°C to produce anhydrous AlCl 3 ;

[0032] (2) Electrolysis of aluminum chloride to produce aluminum-magnesium alloy: graphite is used as a bipolar electrode with a pole distance of 1 cm. The electrolyte system used is composed of flux, melt and additives. The composition of the flux is: NaCl: 23.7 %, KCl: 33.5%, MgCl 2 : 42.8%, then add molten AlCl that ac...

Embodiment 2

[0034] (1) Acid leaching of low-grade bauxite to produce aluminum chloride: Grind the ore sample 2 shown in Table 1 to 100-200 μm, mix it with sulfuric acid at a mass ratio of 1:5, filter it, and react at 150°C 2h, add 4 times the mass of water to the filter residue, boil and dissolve at 75°C for 45 minutes, dissolve the reactant, remove the residue by filtration, and obtain an aluminum sulfate solution, concentrate the aluminum sulfate solution to a density of 1.4g / mL, and the mass concentration It is mixed with 25% hydrochloric acid, and then HCl gas is introduced to precipitate AlCl 3 ·6H 2 O crystals, dried and dehydrated at 120°C to produce anhydrous AlCl3 ;

[0035] (2) Electrolysis of aluminum chloride to produce aluminum-magnesium alloy: silicon carbide is used as a bipolar electrode with a pole distance of 1.5cm. The electrolyte system used is composed of flux, melt and additives. The flux is: NaCl: 39.6% by mass %, KCl: 26.5%, MgCl 2 :33.9%, then add molten AlCl t...

Embodiment 3

[0037] (1) Acid leaching of low-grade bauxite to produce aluminum chloride: Grind the kaolin shown in Table 2 to 100-200 μm, mix it with sulfuric acid at a mass ratio of 1:6 for leaching reaction, filter, and react at 350°C for 1 hour , add 5 times the mass of water to the filter residue, boil and dissolve at 80°C for 45 minutes, dissolve the reactant, filter to remove the residue, and obtain an aluminum sulfate solution, concentrate the aluminum sulfate solution to a density of 1.4g / mL, and the mass concentration is 18% hydrochloric acid is mixed, and then HCl gas is introduced to precipitate AlCl 3 ·6H 2 O crystals, dried and dehydrated at 130°C to produce anhydrous AlCl 3 ;

[0038] (2) Electrolysis of aluminum chloride to produce aluminum-magnesium alloy: graphite is used as a bipolar electrode with a pole distance of 2.5cm. The electrolyte system used is composed of melt, melt and additives. The composition of the flux is: KCl: 67.0%, MgCl 2 : 33.0%, then add molten A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com