Reinforced cold-bent concrete-filled steel tube column, structure system and construction method

A technology for concrete-filled steel tubular columns and reinforced concrete, which is applied in the directions of columns, piers, pillars, etc., can solve the problems of poor construction quality, slow construction speed, poor seismic effect, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

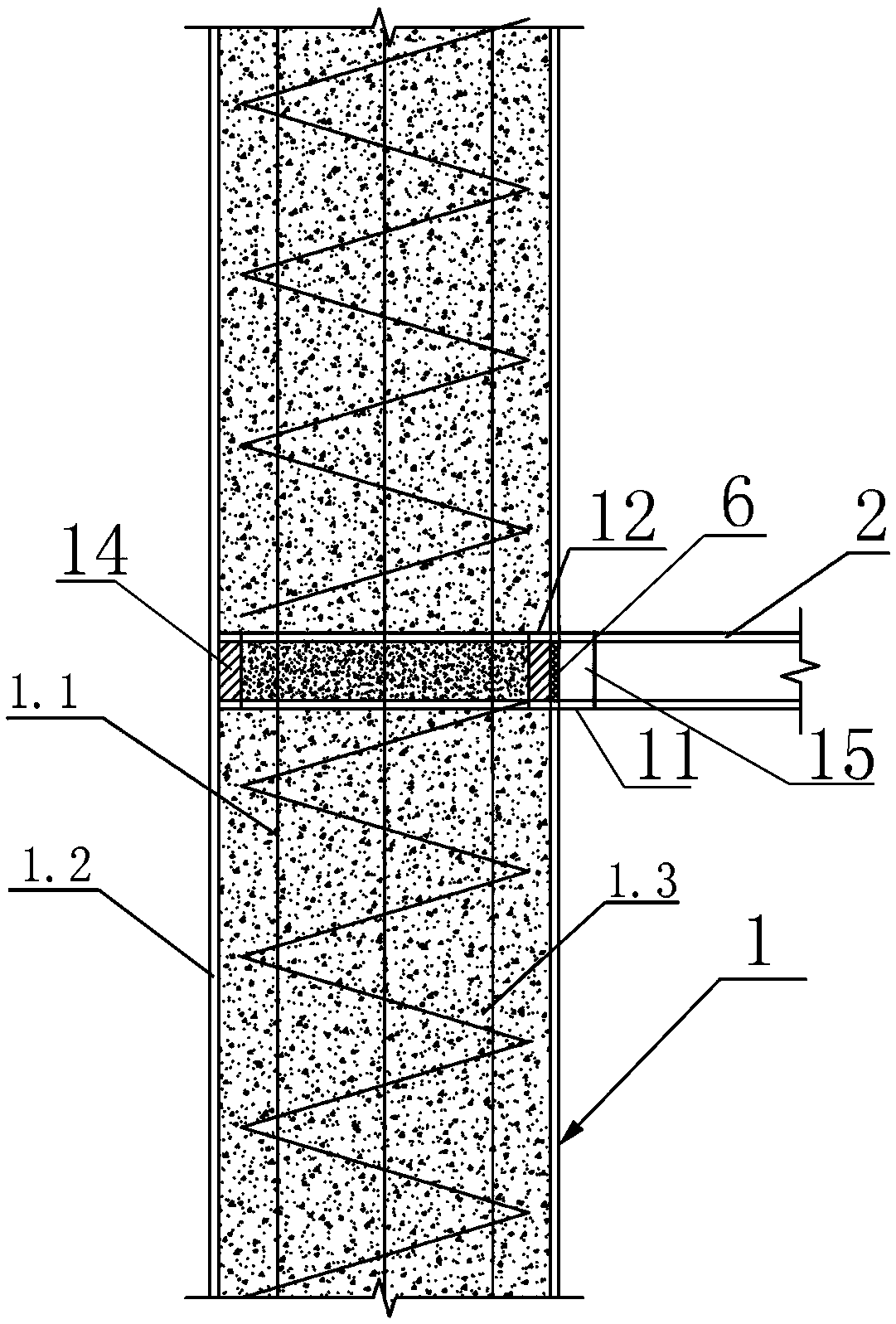

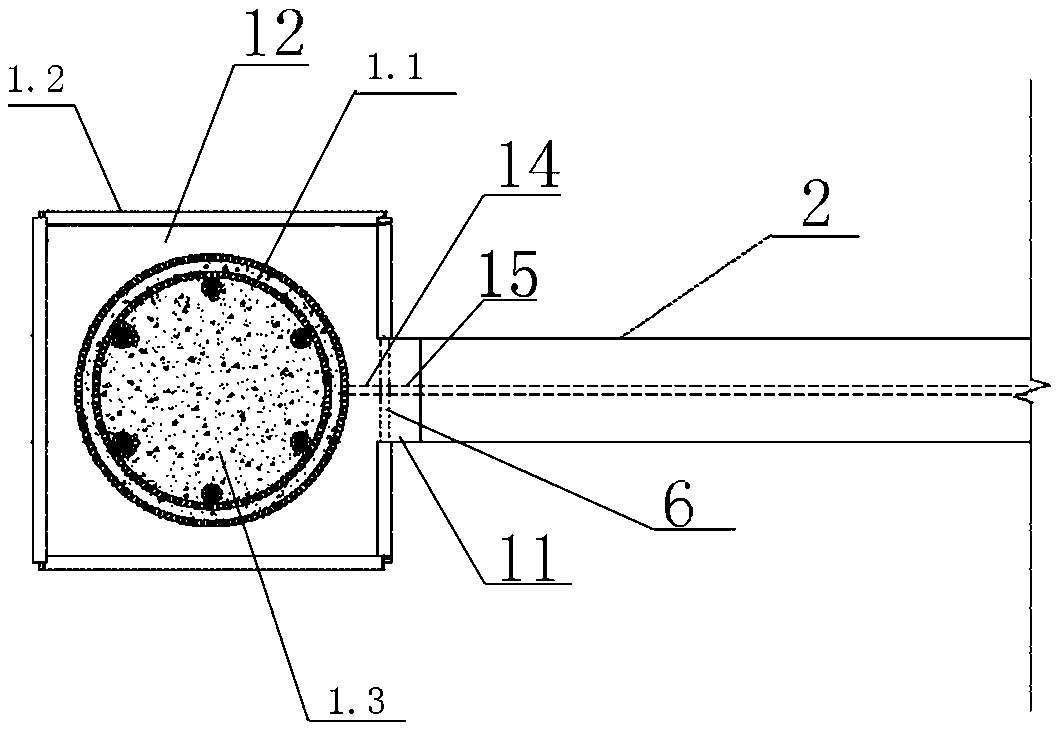

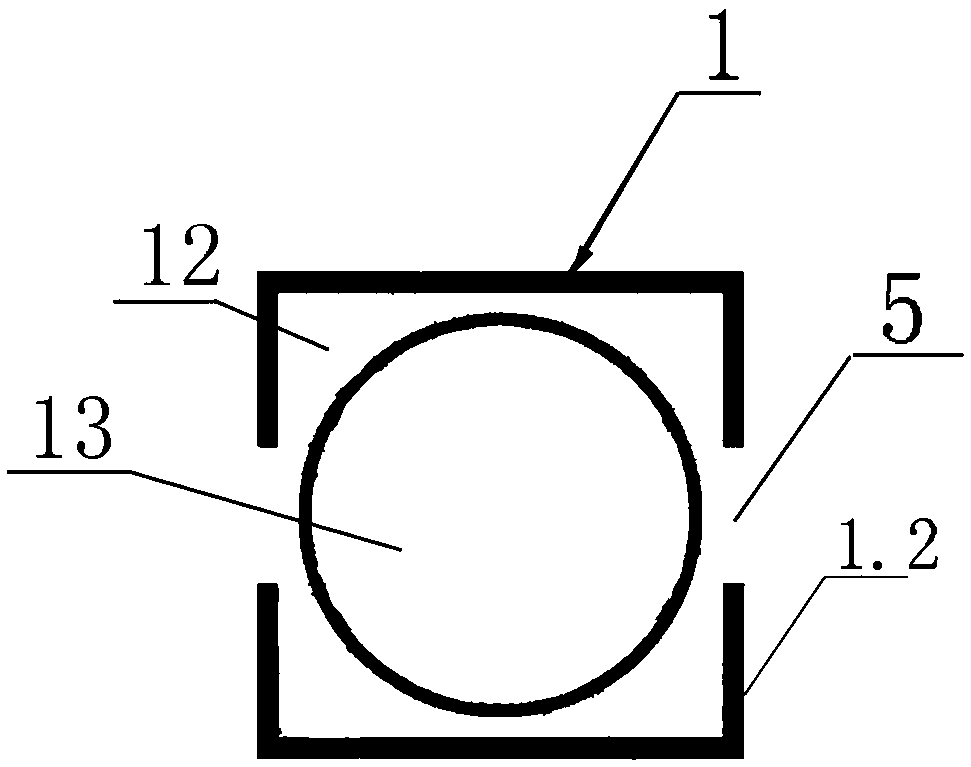

[0064] Such as Figure 1-3 As shown, this reinforced cold-formed steel pipe concrete column includes a steel pipe column main body 1.2 and column concrete 1.3 poured in the steel pipe column main body 1.2; the steel pipe column main body 1.2 is made of cold-formed steel pipe, and On the column main body 1.2, there is a hole 5 at the position connected with the structural beam to be installed; inside the steel pipe column main body 1.2, on the upper side and the lower side of the hole 5, there are respectively horizontal stiffening plates 12, two horizontal stiffening plates 12 A first vertical stiffening plate 14 is connected between them; the shape of the horizontal stiffening plate 12 is adapted to the cross-sectional shape of the steel pipe column main body 1.2, and the edge of the horizontal stiffening plate 12 is welded to the side wall of the steel pipe column main body 1.2; The plate surface of the horizontal stiffening plate 12 is provided with a perforation 13; the fi...

Embodiment 2

[0095] Such as Figure 4-7 As shown, this reinforced cold-formed steel pipe concrete column includes a steel pipe column main body 1.2 and column concrete 1.3 poured in the steel pipe column main body 1.2; the steel pipe column main body 1.2 is made of cold-formed steel pipe, and On the column main body 1.2, there is a hole 5 at the position connected with the structural beam to be installed; in the interior of the steel pipe column main body 1.2, on the upper side and the lower side of the hole 5, horizontal stiffening plates 12 are respectively provided, and the horizontal stiffening plates 12 Set along the cross-section transverse axis of the steel pipe column main body 1.2, the lateral sides of the horizontal stiffening plate 12 and the steel pipe column main body 1.2 are respectively spaced apart, and the gap between the horizontal stiffening plate 12 and the steel pipe column main body 1.2 forms the perforation 13. The end of the horizontal stiffening plate 12 protrudes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com