Architecture structure system assembled by composite building board and building method

A technology for building structures and building boards, applied in building structures, building components, buildings, etc., can solve problems such as glass wool dust pollution, foam plastics are flammable, and consume petroleum resources, so as to reduce construction costs and realize production integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

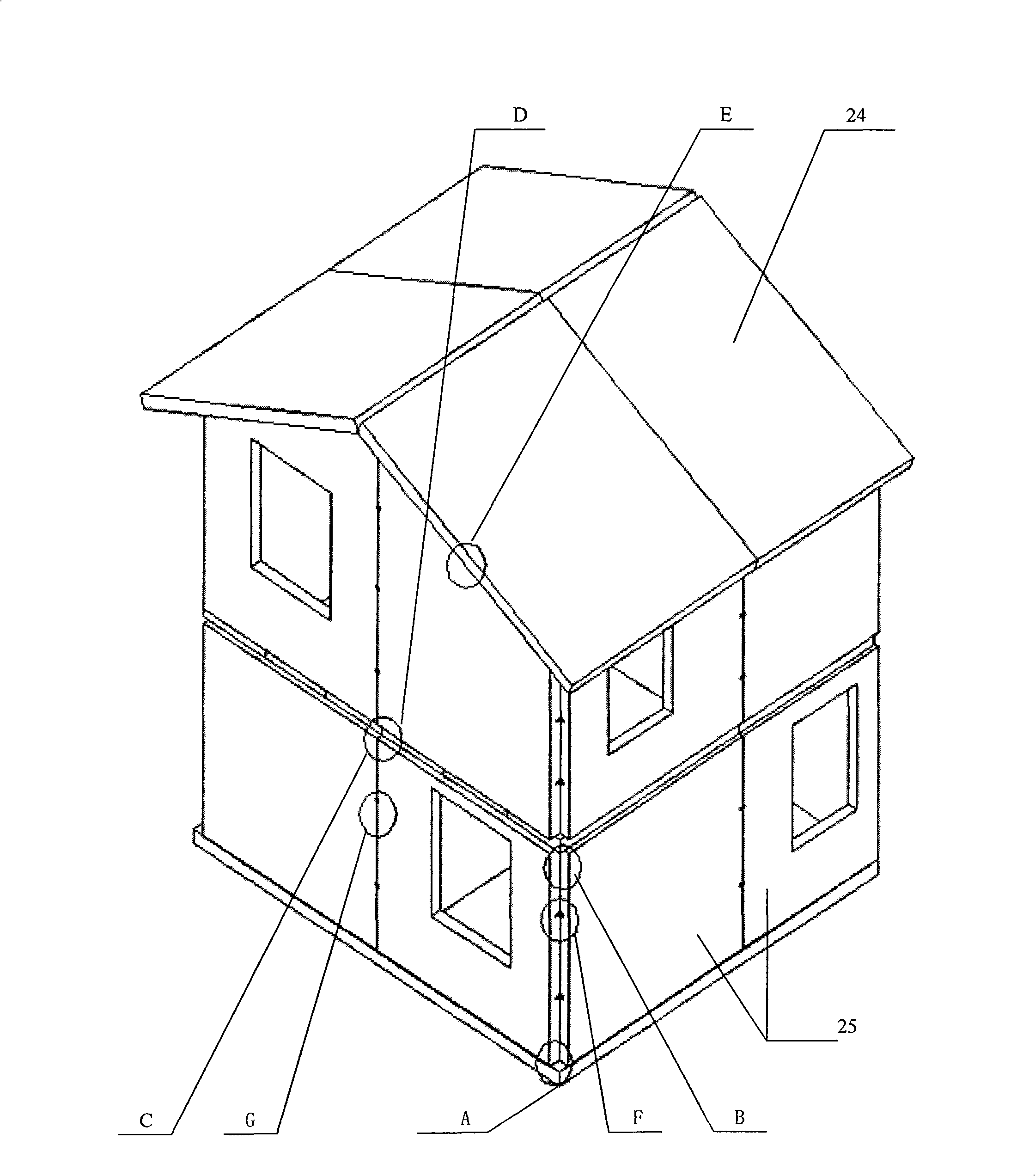

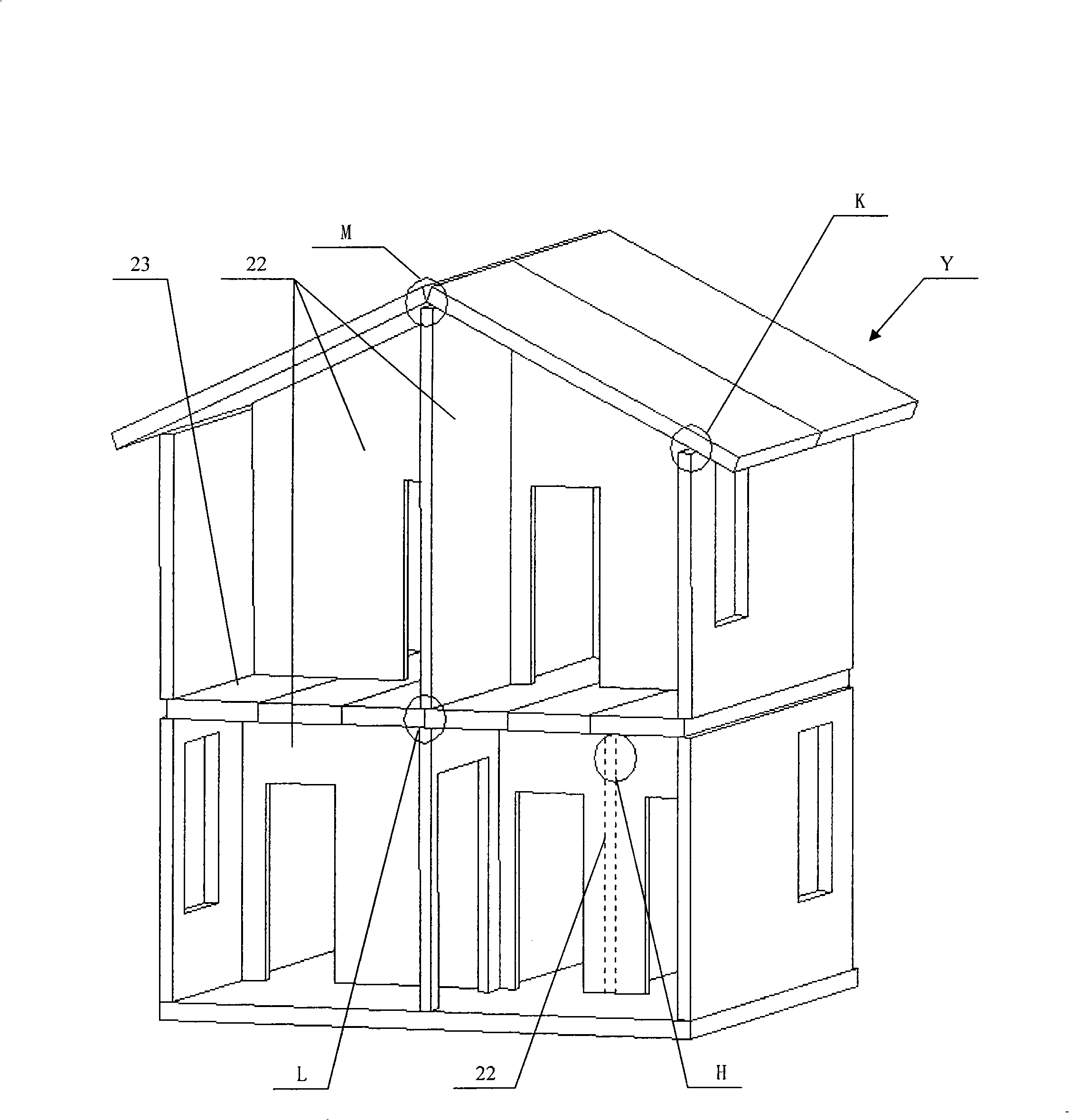

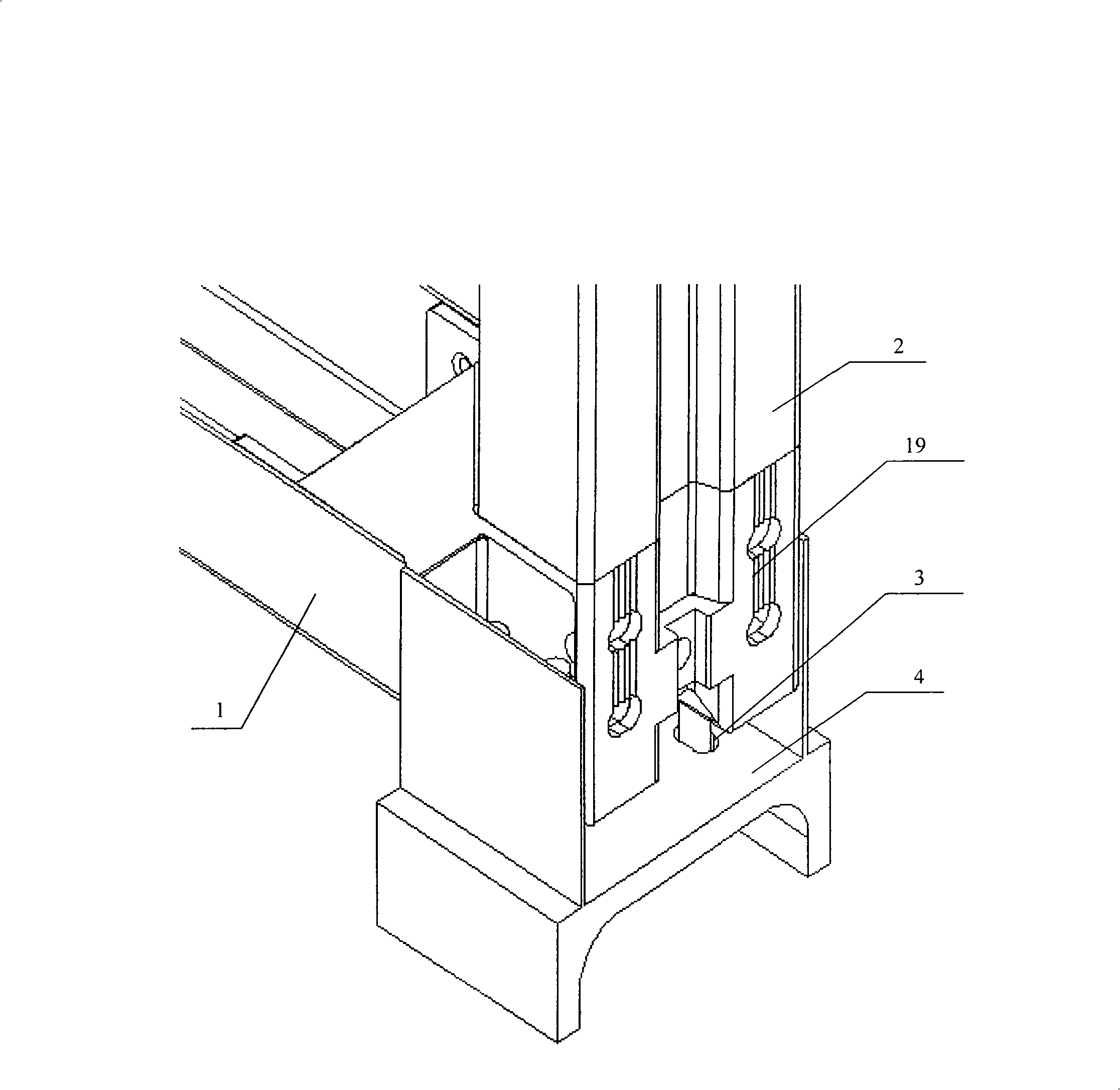

[0064] The building structure system of the present invention, such as figure 1 , figure 2 As shown, it is composed of load-bearing partition wall panels 22 and exterior wall panels 25 containing the functions of building beams and columns, floor slabs 23 and roof panels 24 with integrated functions of slabs and beams, and A, B, C, D, E, The wall panels of F, G, H, L, M, and K positions are provided with structural connectors inside the panels.

[0065] The construction method of the present invention uses the internal structural connectors and the external structural connectors, which include: wall bottom connectors, corner connectors, positioning connectors, floor and exterior wall panels, partition wall panel connectors, roof and exterior Connectors such as walls, gable connectors, and ridge connectors are constructed by connecting exterior wall p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com