Automatic batching system

A technology for automatic batching and material, applied in the field of warehouse management, can solve problems such as low efficiency and achieve the effect of production integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

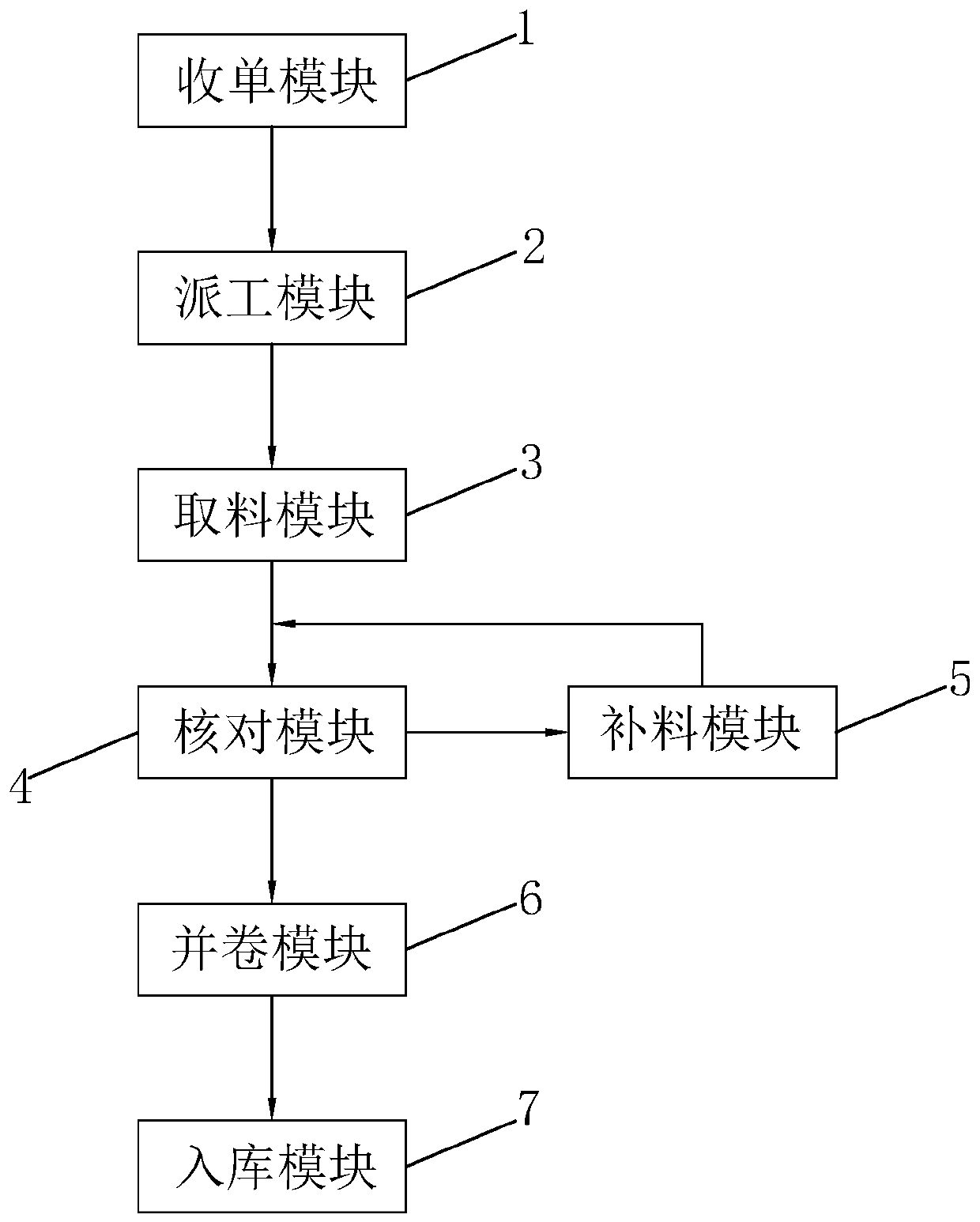

[0018] The invention provides an automatic batching system, which is suitable for batching paper rolls in printing factories. Such as figure 2 As shown, the automatic batching system includes a receiving module 1, a dispatching module 2, a retrieving module 3, a checking module 4, a feeding module 5, a winding module 6 and a storage module 7.

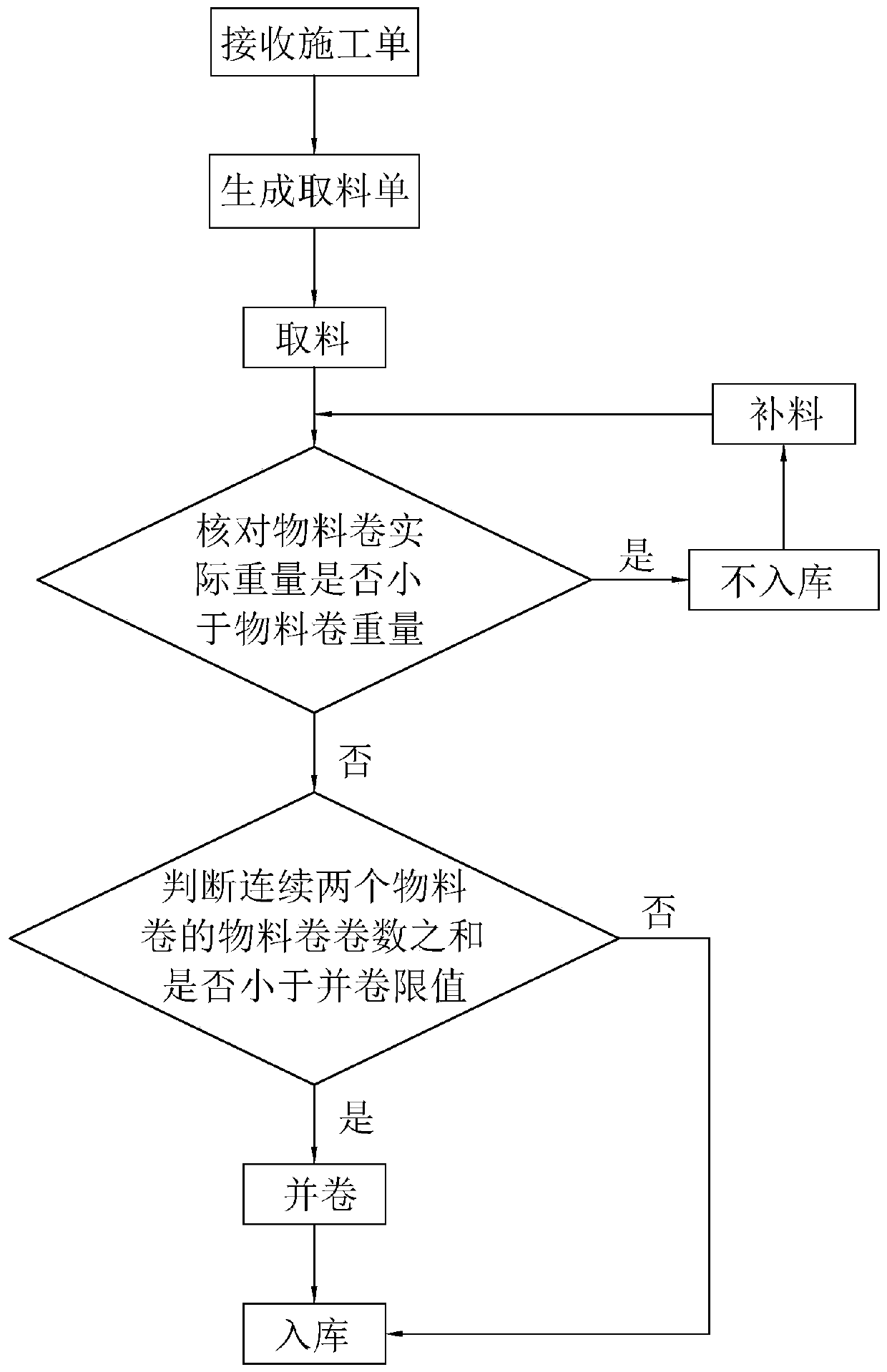

[0019] Such as figure 1 As shown, the batching process of the automatic batching system is as follows:

[0020] (1) Receive construction orders

[0021] In this embodiment, this step is implemented by the acquiring module 1, and the acquiring module 1 is used to receive the construction order, wherein the construction order includes the name of the material volume, required weight, door width and grammage, etc.

[0022] (2) Generate a pick-up list

[0023] In this embodiment, this step i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com