A kind of green lost foam casting method

A lost foam casting and green technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of polluted gas, lost foam denaturation, and difficulty in taking out lost foam, so as to improve the quality of castings and avoid foam plastic denaturation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 16

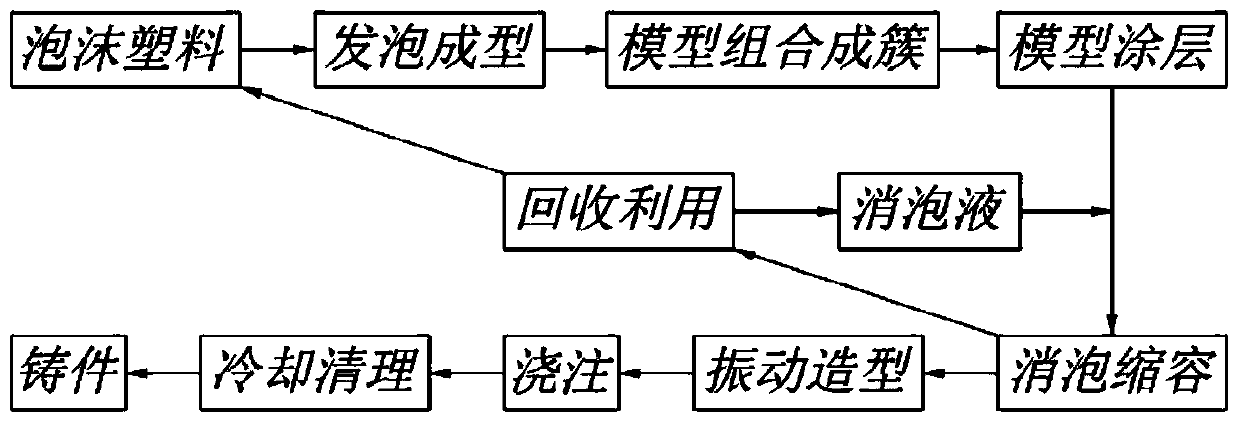

[0026] A green lost foam casting method, its technological process is shown in figure 1 , including the following steps:

[0027] (1) Selection of foamed plastics: There are three types of foam beads for lost foam casting: 1) Expandable polystyrene resin (EPS); 2) Expandable methyl methacrylate and styrene copolymer resin (STMMA) 3) Expandable polymethyl methacrylate resin (EPMMA). Expandable polystyrene resin (EPS) is commonly used for casting non-ferrous metals, gray iron and general steel casting. The foamed plastic beads are translucent beads, the pre-expansion multiple is 40-60, and the particle size is 0.18-0.80 mm. 10.

[0028] (2) Foaming into a vanishing model: The foamed plastic is molded into a vanishing model through pre-foaming-curing-foaming molding-cooling, and a vanishing model can also be directly made of a foamed plastic sheet.

[0029] (3) The model is combined into a vanishing model cluster: the processed vanishing model and the pouring riser are bonded...

Embodiment 17

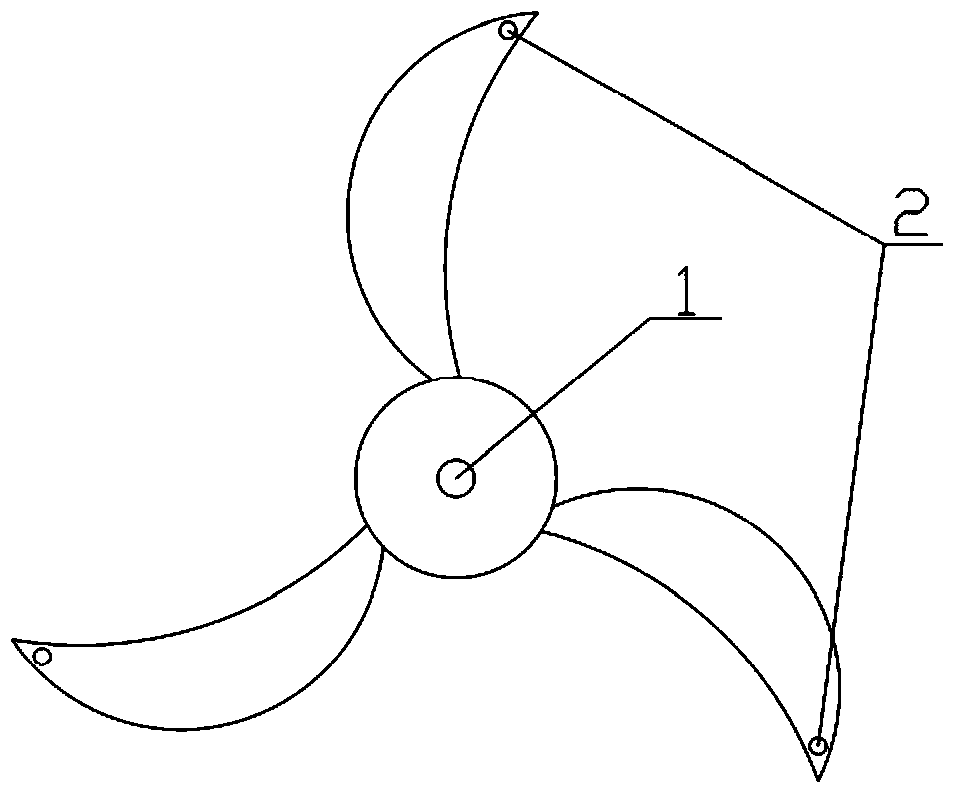

[0037] A green lost foam casting method (casting to produce a marine propeller), see figure 2 , the volume is about 2000cm 3 , in the figure 1 is the pouring port, and 2 is the 3 emptying ports.

[0038] The expandable methyl methacrylate and styrene copolymer resin beads (STMMA) are pre-expanded-cured-foamed-molded-cooling to form the disappearance model of the marine propeller, which is combined with the pouring riser and bonded together. Form disappearing model clusters, brush refractory paint on the outer surface of the disappearing model clusters, and dry them so that the refractory coating layer forms a mold shell, add the defoaming liquid of Example 6 into the mold shell through the pouring riser, and defoaming the disappearing model for 30 minutes. The volume is reduced into a mixed liquid, and the mixed liquid is automatically flowed out from the pouring riser and recycled. The mold shell with the pouring riser is vibrated to shape, and the molten metal is poured in...

Embodiment 18

[0041] A green lost foam casting method. Expandable polymethyl methacrylate resin beads (EPMMA) are made into lost models. The outer surface of the cluster is brushed with refractory paint, dried to make the refractory paint layer form a mold shell, and the defoaming liquid of Example 13 is added to the mold shell through the pouring riser, and the model disappears for about 30 minutes, defoaming and shrinking into a mixed liquid. The air is inflated to blow out the mixed liquid and recycled, and the mold shell with the pouring riser is vibrated to shape, and the molten metal liquid is poured into the mold shell through the pouring riser, and the casting is formed after solidification and cooling.

[0042] The mixed liquid is recovered by vacuum distillation, the casting quality is good, and there is no defect and the appearance of crystalline carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com