A kind of organosilicon modified amphoteric waterborne polyurethane emulsion and preparation method thereof

A water-based polyurethane and silicone technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor hand feeling, poor elasticity, hard water-based polyurethane film, etc., and achieve good fluidity and storage stability, crystallization High performance, fast solvent evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

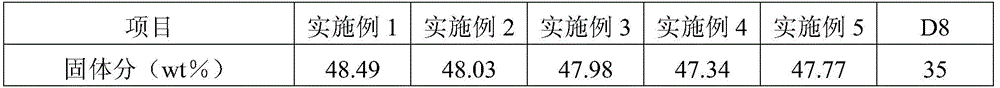

Examples

Embodiment 1

[0054] A silicone-modified amphoteric waterborne polyurethane emulsion. The formula composition and dosage are shown in Table 1. The specific preparation steps are as follows:

[0055] Add the formulated amount of polyoxypropylene glycol and sulfonic acid group-containing polyester diol into a polymerization reactor equipped with a digital display electric mixer and a thermometer. The temperature is raised to 110°C, and the water is removed by vacuum distillation and heat preservation. The water time is 2h. After the water removal is completed, the temperature is reduced to 60~70℃; the catalyst dibutyltin dilaurate and isophorone diisocyanate are added to the above polymerization reactor, the temperature is raised to 85℃, and the reaction is stirred for 3h; then the temperature is reduced to 60 ℃, add acetone, stir for 10min, add triethanolamine and 1,4-butanediol, stir for 3h; then cool to 50℃, add glacial acetic acid, stir for 0.5h; transfer the reaction product in the polymeriz...

Embodiment 2

[0059] A silicone-modified amphoteric waterborne polyurethane emulsion. The formula composition and dosage are shown in Table 2. The specific preparation steps are as follows:

[0060] Add the formulated amount of polyoxypropylene glycol and sulfonic acid group-containing polyester diol into a polymerization reactor equipped with a digital display electric mixer and a thermometer. The temperature is raised to 110°C, and the water is removed by vacuum distillation and heat preservation. The water time is 2h. After the water removal is completed, the temperature is reduced to 60~70℃; the catalyst dibutyltin dilaurate and isophorone diisocyanate are added to the above polymerization reactor, the temperature is raised to 85℃, and the reaction is stirred for 3h; then the temperature is reduced to 60 ℃, add acetone, stir for 10min, add triethanolamine and 1,4-butanediol, stir for 3h; then cool to 45℃, add glacial acetic acid, stir for 0.75h; transfer the reaction product in the polymeri...

Embodiment 3

[0064] A silicone modified amphoteric waterborne polyurethane emulsion, the formula composition and dosage are shown in Table 3. The specific preparation steps are as follows:

[0065] Add the formulated amount of polyoxypropylene glycol and sulfonic acid group-containing polyester diol into a polymerization reactor equipped with a digital display electric mixer and a thermometer. The temperature is raised to 110°C, and the water is removed by vacuum distillation and heat preservation. The water time is 2h. After the water removal is completed, the temperature is reduced to 60~70℃; the catalyst dibutyltin dilaurate and isophorone diisocyanate are added to the polymerization reactor, the temperature is raised to 80℃, and the reaction is stirred for 3.5h; then the temperature is reduced to 55℃, add acetone, stir for 10min, add triethanolamine and 1,4-butanediol, stir and react for 4h; then cool to 50℃, add glacial acetic acid, stir for 0.5h; transfer the reaction product in the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com