Preparation and application of aluminium-phosphate-cladded carbon-cladded Li4Ti5O12/TiN

A technology of lithium titanate nitride and carbon coating, which is applied in the field of nanomaterials to achieve high gram capacity, high conductivity, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation method of the aluminum phosphate-coated carbon-coated lithium titanate nitride comprises the following steps:

[0055] Step 1) preparation of lithium titanate

[0056] Lithium carbonate and rutile titanium dioxide were weighed according to the Li:Ti molar ratio of 0.8:1, mixed with absolute ethanol, and ball milled in an argon atmosphere in a QM-2SP12 ball mill of Nanjing University Instrument Factory for 12 hours. The uniformly mixed sample was placed in a vacuum oven at 80°C, heated and dried for 5 hours, and then cooled to room temperature under vacuum. Put the sample in JQF1400-30 high-temperature atmosphere electric furnace of Shanghai Jiugong Electric Co., Ltd., vacuumize, pass 99.9% nitrogen protective gas, then raise the temperature to 500°C at a speed of 5°C / min, and keep it at this temperature for 1 hour, then Continue to raise the temperature to 850° C. at a rate of 2° C. / min, and keep it at this temperature for 1 hour. After natural cooling,...

Embodiment 2

[0068] The preparation method of the aluminum phosphate-coated carbon-coated lithium titanate nitride comprises the following steps:

[0069] Step 1) The preparation of lithium titanate, the reaction environment and conditions are the same as step 1) of Example 1.

[0070] Step 2) Preparation of carbon-coated lithium titanate, the reaction environment and conditions are the same as step 2) of Example 1.

[0071] Step 3) Preparation of carbon-coated lithium titanate nitride

[0072] 30 grams of the carbon-coated lithium titanate particles prepared in step 2) are mixed in an agate ball mill jar by mass percentage 5:100, and 1.5 grams of brown liquid hydrophilic ionic liquid 1-butylpyridine dinitrile amine salt, and added 300 grams of agate grinding balls, protected by argon, planetary ball grinding for 2 hours, rotating speed 300rpm.

[0073] Take out the previous material and place it in a vacuum drying oven at 80°C for 15 hours, grind it evenly and put it into a crucible, th...

Embodiment 3

[0076] The preparation method of the aluminum phosphate-coated carbon-coated lithium titanate nitride comprises the following steps:

[0077] The reaction environment and conditions of step 1), 2) 3) and 4) are the same as in Example 2, the difference is that in step 3), the nitrogen source is a hydrophilic colorless liquid ionic liquid 1-butyl-3-formazan imidazole dicyanamide salt.

[0078] The product of step 3) is gray carbon-coated lithium titanate nitride powder. The carbon coating contains pyrolytic carbon and carbon nitride (CN X ) compounds. Among them, carbon nitride (CN X ) compounds are highly conductive.

[0079] Material Characterization

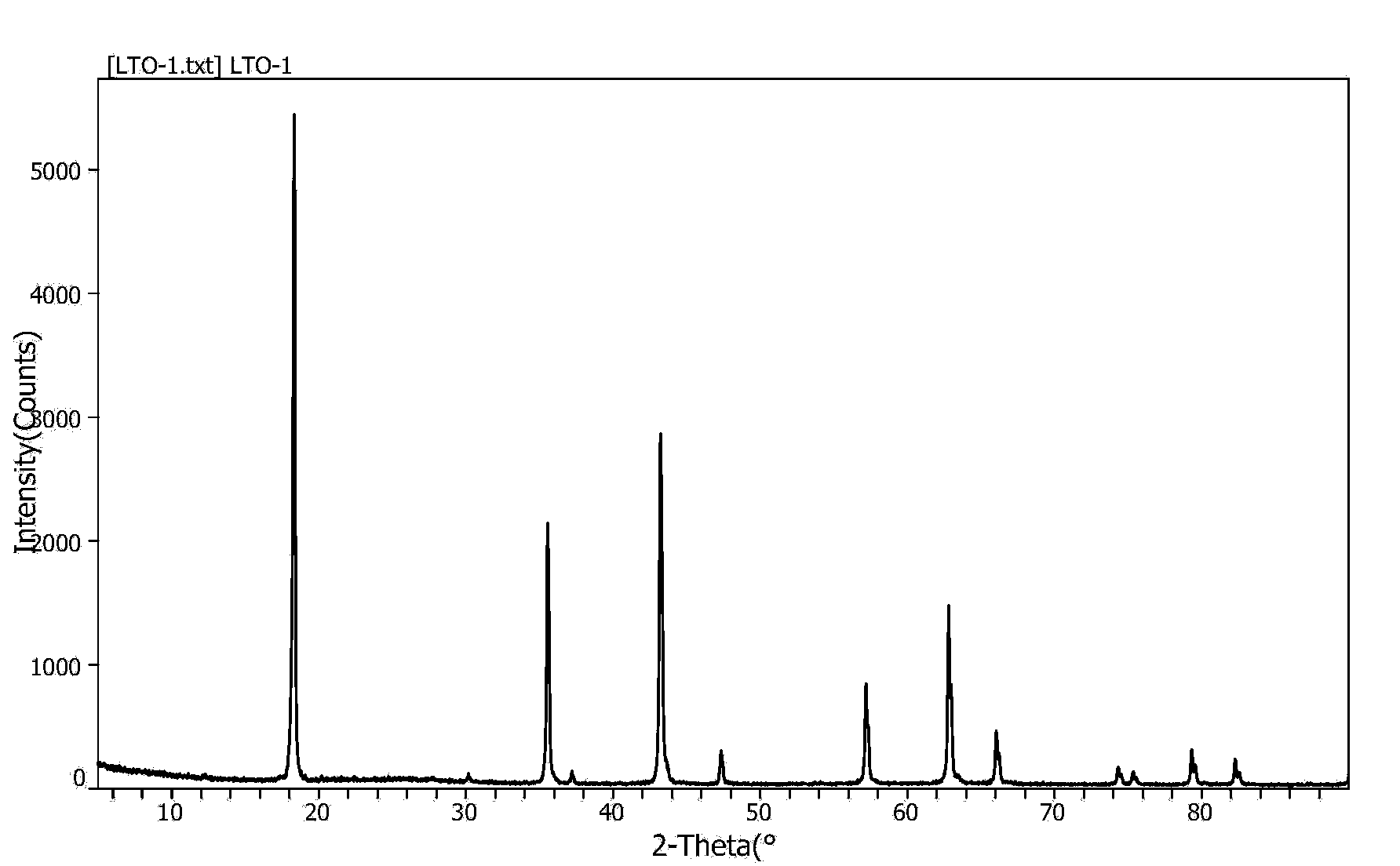

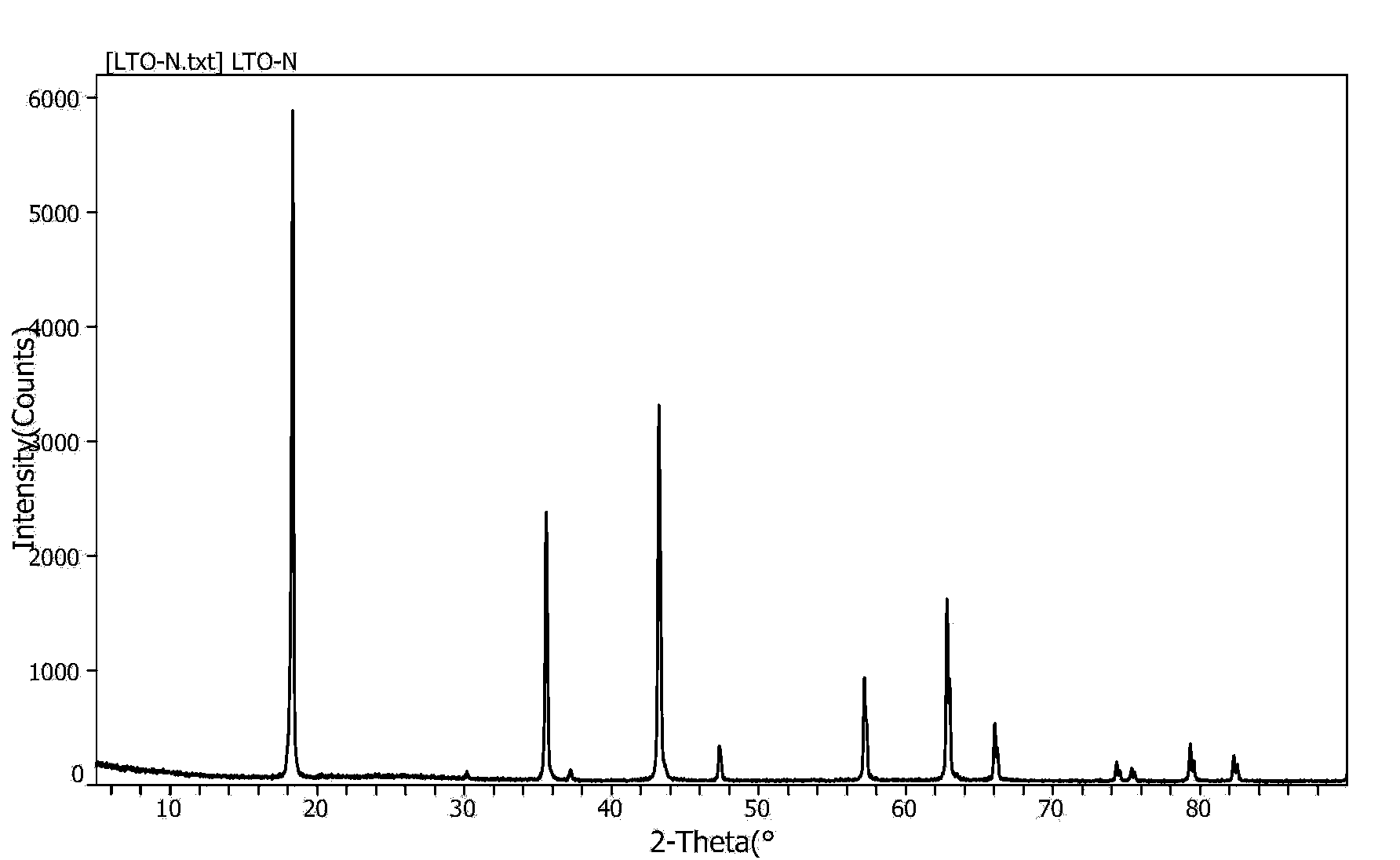

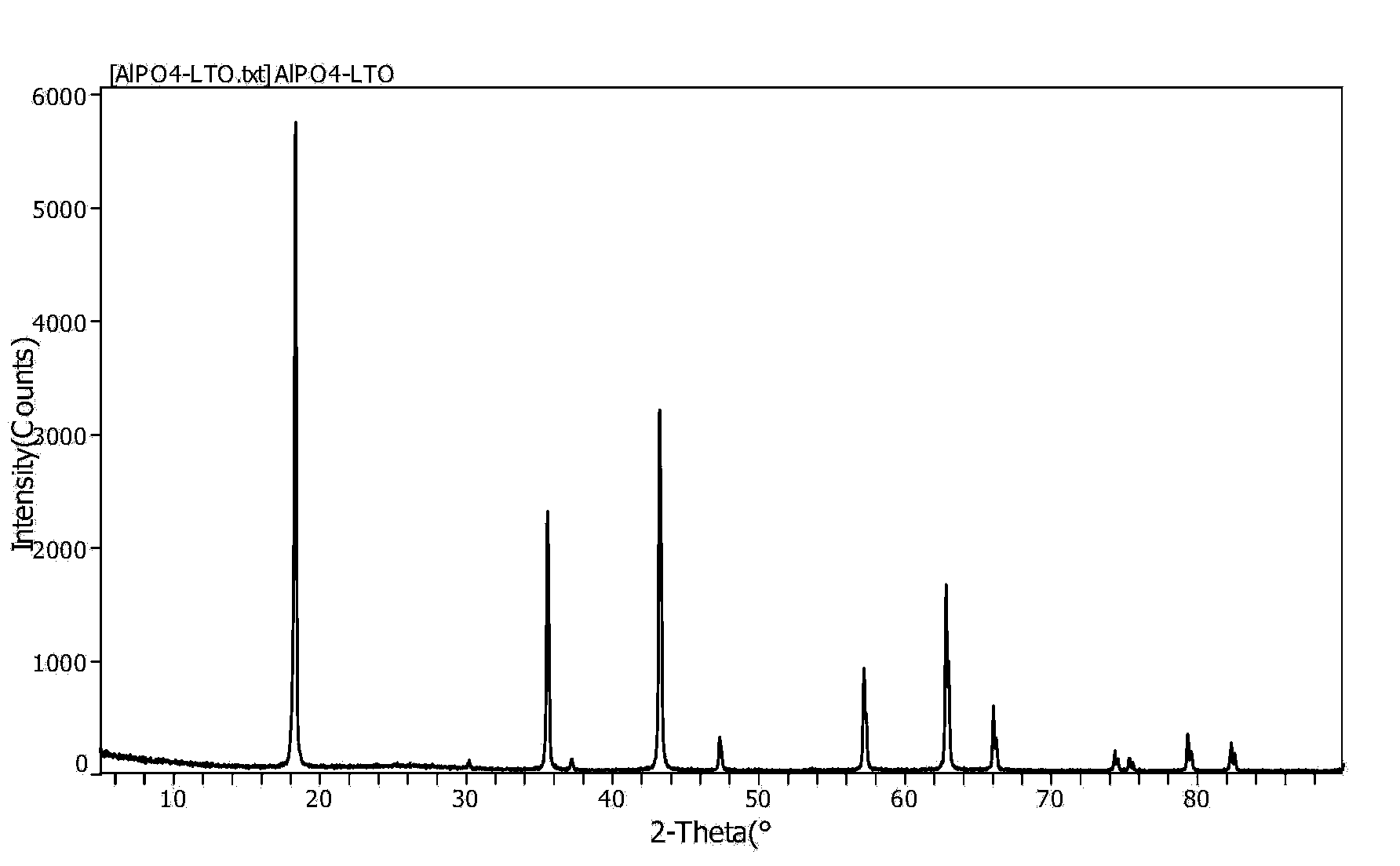

[0080] 1) The crystal structure test was carried out on the Shimadzu X-ray diffractometer XRD-7000, using a copper target, the scanning speed was 2° / min, the test accuracy was ±0.04°, and the scanning range was 5-90°.

[0081] The spinel structure carbon-coated lithium titanate XRD spectrum pattern that embodiment 1 step 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com