Fluorescence sensor for detecting pyrophosphatase and preparation method thereof

A fluorescence sensor and pyrophosphatase technology, applied in the field of analytical chemistry, can solve the problems of inconvenient operation, complicated operation, high price and the like, and achieve the effects of strong practicability, simple operation steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

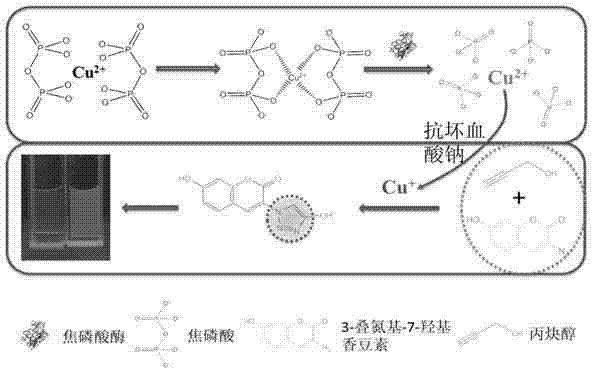

[0029] The following examples illustrate the application of the method of the present invention to prepare a fluorescent pyrophosphatase sensor and apply it to the detection of the pyrophosphatase inhibitor sodium fluoride concentration in conjunction with the accompanying drawings:

[0030] 1. Pyrophosphatase hydrolyzes pyrophosphate. Specific steps are as follows:

[0031] A. Weigh the enzyme lyophilized powder to make a mother solution with a certain weight of 1 U / μL, and dilute it to the required concentration according to the gradient;

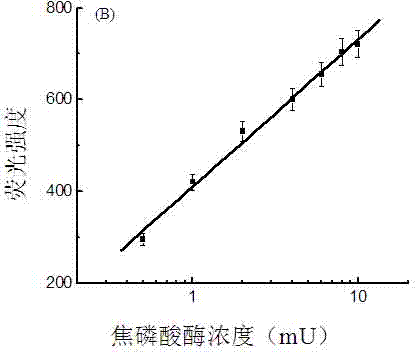

[0032] B. Add 2 μL of pyrophosphatase with different gradients to 4-hydroxyethylpiperazineethanesulfonic acid buffer solution (10mM HEPES, pH=7.2) containing 125 μM pyrophosphate, mix well, and place in a 37°C water bath for 60 minutes at room temperature ;

[0033] C. Add 2 μL of copper sulfate solution with a concentration of 10 mM to the mixed solution, and continue the reaction in a 37° C. water bath for 20 minutes.

[0034] 2. Cli...

Embodiment 2

[0038] 1. Detection of pyrophosphatase inhibitor sodium fluoride concentration, the specific steps are as follows:

[0039] Add 0 μM, 2.0 μM, 1.6, 1.2 μM, 0.8 μM and 0.4 μM enzyme inhibitor sodium fluoride to the buffer containing 4.0 mU pyrophosphatase respectively, and after standing at room temperature for 30 minutes, add 125 μM pyrophosphoric acid in a water bath at 37°C for 60 Minutes, then add 100 μM copper sulfate, continue to keep warm in water bath for 20 minutes, finally add the click reagent and keep it in the dark for 15 minutes, measure the fluorescence with a fluorescence spectrophotometer, and record the data.

[0040] 2. The method of the present invention prepares the specificity of pyrophosphatase detection of the fluorescent pyrophosphatase sensor, and the specific steps are as follows:

[0041]In order to detect the specificity of the fluorescent pyrophosphatase sensor of the present invention, the pyrophosphatase used in Example 1-1 was replaced with other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com