Large-area laser impact spot welding method and device based on nano-particle reinforcement

A nanoparticle and laser shock technology, applied in laser welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of difficult application in industrial production, limited service life of welded parts, low tensile shear strength, etc., and achieve improvement. Mechanical properties, precise control of solder joint size, and the effect of increasing microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

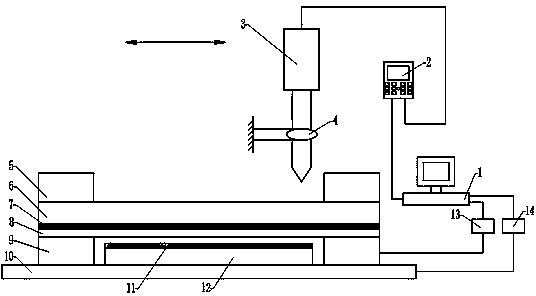

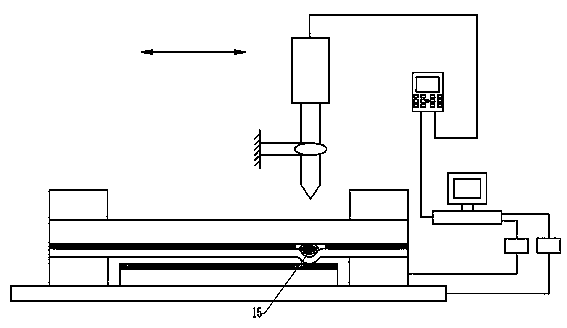

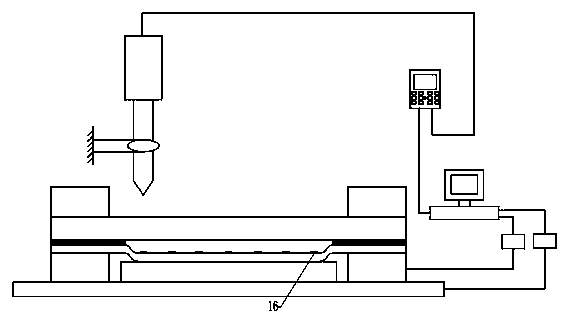

[0037] Specific embodiment 1: 2024 aluminum alloy with a thickness of 1 mm is selected for the workpiece, and T2 red copper with a thickness of 100 microns is selected for the flyer. First, polish the surface of the flyer and workpiece to be welded with 2000# metallographic sandpaper, and wash and dry it with alcohol. Use an inorganic binder (such as sodium silicate binder) to evenly coat silicon carbide particles with a particle size of 50 nm on the welding surface of the workpiece, and the thickness of the nanoparticle coating is 0.05 mm. Choose a transparent PC board coated with black paint with a thickness of 3 mm as the constraining layer, and use a cyanoacrylate adhesive to bond the flyer to the surface of the constraining layer coated with black paint. After the welding system composed of the workpiece, flyer and constrained layer is installed, adjust the three-coordinate moving platform to the preset welding station, use a strong pulse Nd:YAG laser to emit pulsed laser...

specific Embodiment 2

[0040] The difference between the second embodiment and the first embodiment is that the particle size of the nanoparticles is 10 nanometers, the thickness of the coating is 0.1 mm, the thickness of the flyer is 250 microns, the diameter of the laser spot is 7 mm, and the energy is 3 joules. This specific embodiment one is similar.

specific Embodiment 3

[0042] The difference between the third embodiment and the first embodiment is that the nanoparticles are titanium carbide, the particle size is 100 nanometers, the thickness of the coating is 0.5 mm, the thickness of the flyer is 500 microns, the diameter of the laser spot is 10 mm, and the energy is 50 μm. The welding effect is similar to that of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com