Semi-coke waste heat recovery system

A waste heat recovery system and blue carbon technology are applied in the steam generation method using heat carrier and other directions, which can solve the problems of water resource consumption, energy consumption, blue carbon waste, etc., and achieve enhanced heat exchange effect, good cooling effect, and low pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

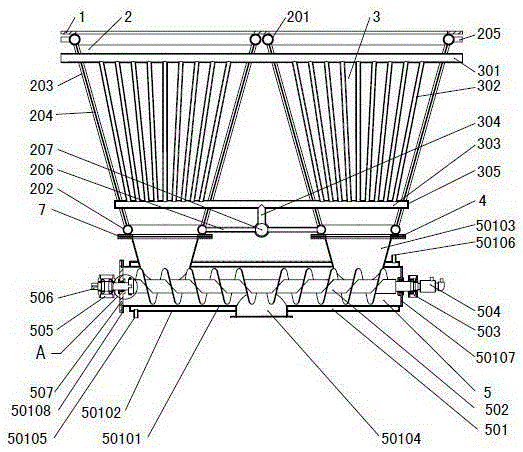

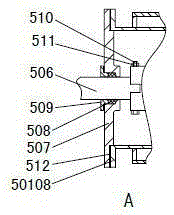

[0045] refer to figure 1 , the semi-coke waste heat recovery system of this embodiment is composed of a heat exchanger and a water-cooled screw conveyor 5, a plurality of coke discharge ports are arranged below the carbonization furnace, and two heat exchangers are fixed side by side on the carbonization furnace (not shown in the figure) ) below a coke discharge port, there are multiple water-cooled screw conveyors 5, each water-cooled screw conveyor 5 is fixed below the two heat exchangers, and two first inlets are arranged on the upper side of the water-cooled screw conveyor 5 The feed port 50103 and the two first feed ports 50103 are respectively connected to the discharge port of the heat exchanger, and the lower side of the water-cooled screw conveyor 5 is provided with a first discharge port 50104.

[0046] Preferably, the heat exchanger includes an outer heat exchanger 2 for enclosing a high-temperature material passage and an inner heat exchanger 3 located at the cente...

Embodiment 2

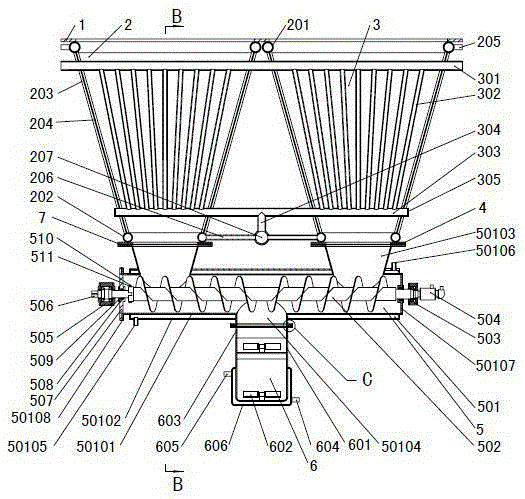

[0055] refer to image 3 , 5 , The difference between this embodiment and Embodiment 1 is that the semi-coke waste heat recovery system also includes a water-cooled scraper conveyor 6 . The water-cooled scraper conveyor 6 is located directly below the first outlet 50104 of all the water-cooled screw conveyors 5. The water-cooled scraper conveyor 6 includes a casing 601, a scraper chain 602, a second feed port 603, a second outlet Feed port (not shown in the figure), reversing wheel assembly, drive wheel assembly and drive assembly. The scraper chain 602 is rotatably arranged in the casing 601 , and a water-cooling jacket outer plate 606 is arranged outside the lower half of the casing 601 , and the water-cooling jacket outer plate 606 and the casing 601 form a water-cooling jacket. One side of the water cooling jacket is provided with a water cooling jacket water inlet pipe 604, and the other side is provided with a water cooling jacket water outlet pipe 605. The scraper ch...

Embodiment 3

[0061] refer to Figure 7 The difference between this embodiment and Embodiment 2 is that the middle part of the inner upper header 301 is fixedly connected with the corresponding heat conduction baffle 204, and the two ends of the inner upper header 301 are slidably connected with the corresponding heat conduction baffle 204 through a telescopic mechanism. Both ends of the inner upper header 301 are slidingly connected to the corresponding heat conduction baffles 204 through a telescopic mechanism. The header 301 and the heat conduction baffle 204 can slide relatively, which not only solves the problem of inconsistent thermal expansion between the inner upper header 301 and the outer heat exchanger 2, improves the working reliability of the heat exchanger, but also solves the problem of gas leakage, improving the Heat exchanger work safety.

[0062] refer to Figure 8 Specifically, the telescopic mechanism includes a sleeve 10 and a second gland 12, the sleeve 10 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com