Preparation method of macromolecular crosslinking agent for ultraviolet light crosslinking polyolefin

A technology of macromolecular crosslinking agent and crosslinking polyolefin, which is applied in the field of preparation of macromolecular crosslinking agent, can solve the problems of easy volatilization and migration, reduction of crosslinking efficiency, pollution of the environment, etc., and achieve high molecular weight and high conversion rate , Easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Under the conditions of nitrogen atmosphere and ice-water bath, 30g 1,6-hexanediol bis(2-mercaptoacetate) and 70.2g triallyl isocyanate were dissolved in 76g toluene respectively, mixed and stirred evenly And add 1.0g of azobisisobutyronitrile, slowly heated to 65 ° C reaction, until the infrared spectrum on the 2570cm -1 The characteristic peak of the mercapto group disappears; after the reaction, the solvent is evaporated to dryness to obtain an allyl-type macromolecular cross-linking agent.

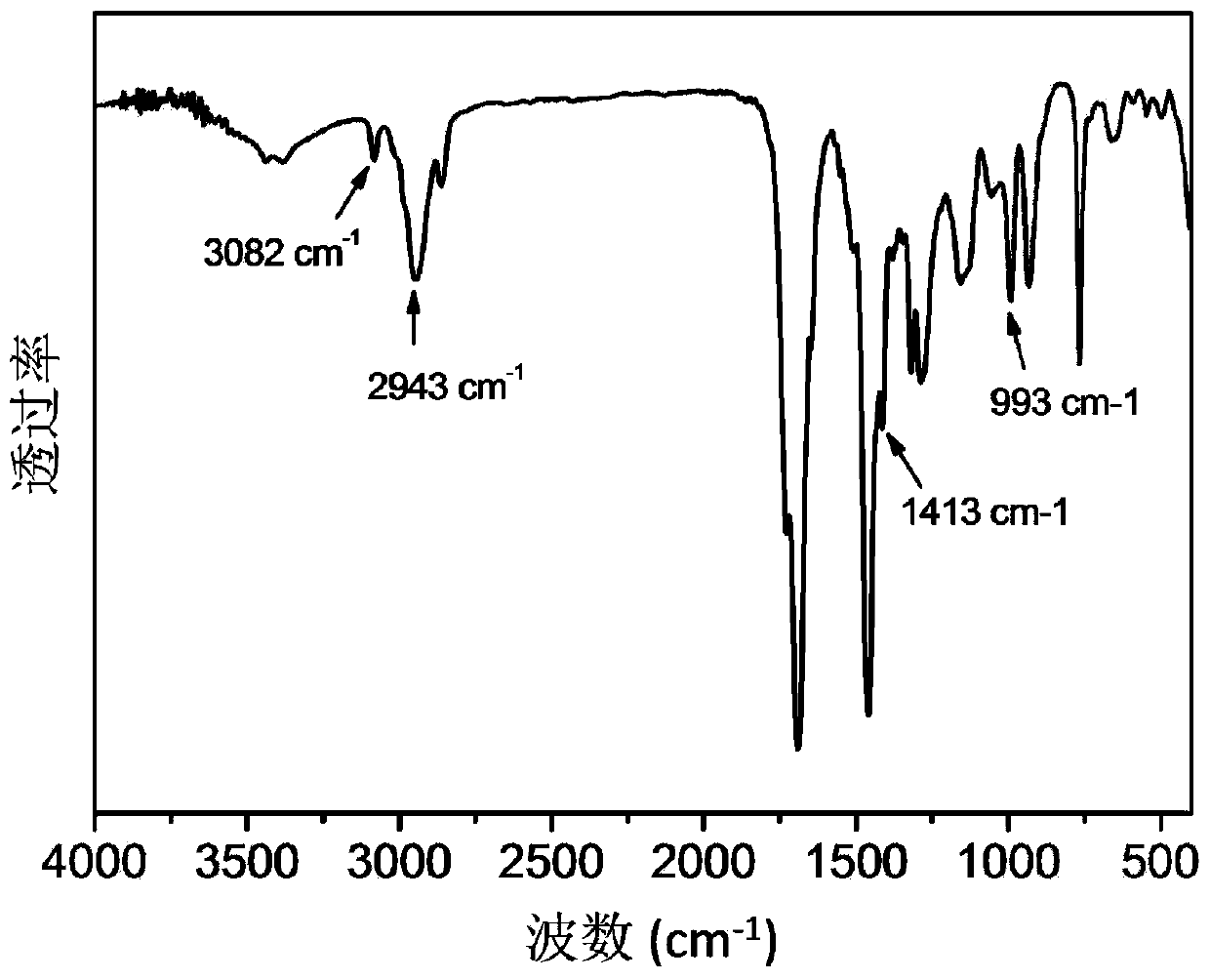

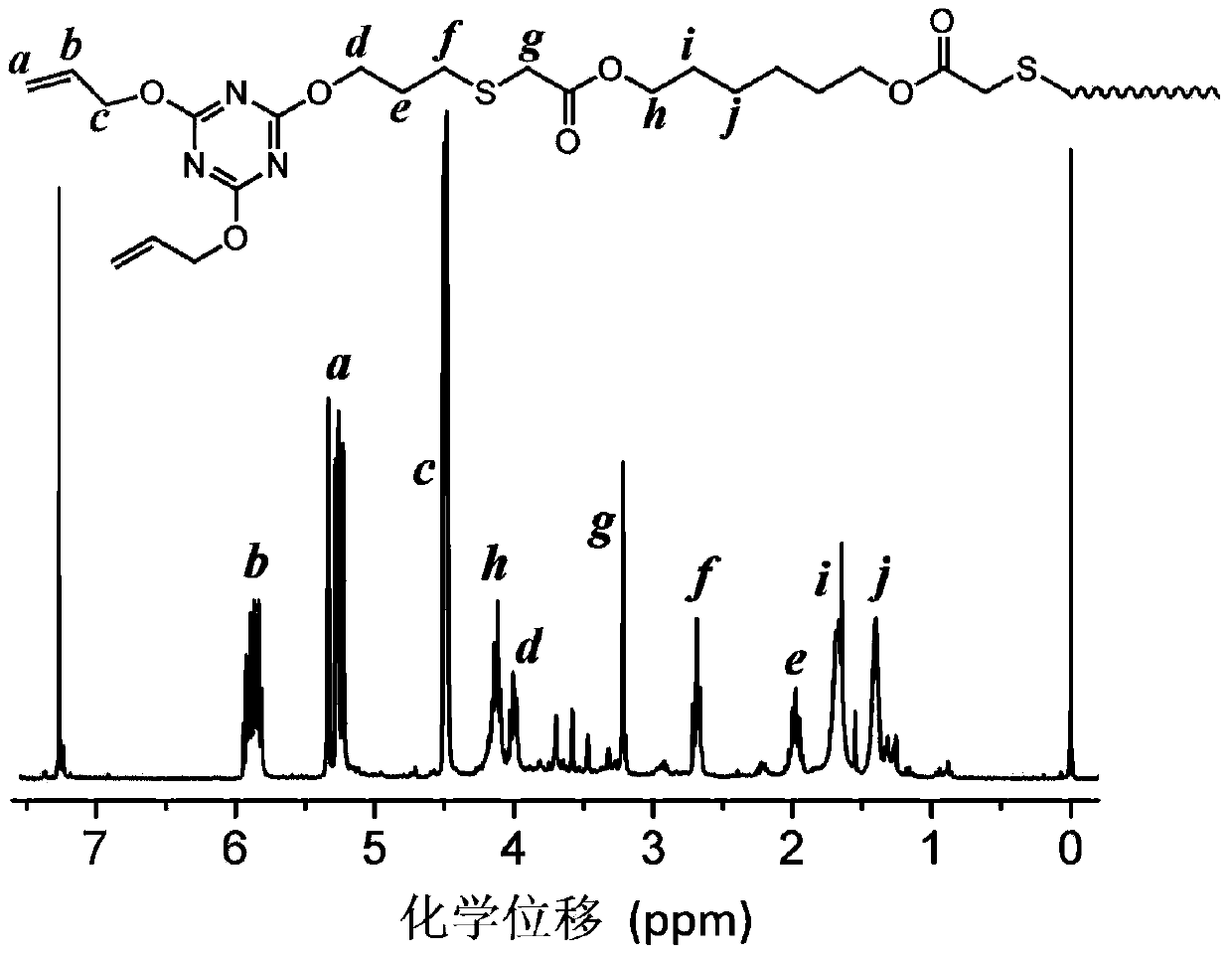

[0027] figure 1 It is the infrared spectrogram of the macromolecular crosslinking agent used for ultraviolet light crosslinking polyolefin prepared in this embodiment. Depend on figure 1 It can be seen that 2570cm -1 The characteristic absorption peak of the sulfhydryl group disappears, indicating that the dithiol compound is completely consumed; 3082cm -1 ,993cm -1 It is the absorption peak of the C-H bond on the allyl group, 2943cm -1 It is the absorption peak of the C-H...

Embodiment 2

[0035] Under nitrogen atmosphere and room temperature, 20g 1,4-butanediol bis(3-mercaptopropionate) and 57.3g trimethylolpropane triallyl ether were dissolved in 77g acetonitrile respectively, mixed and stirred evenly and Add 1.55g benzoin dimethyl ether, at 20mw / cm 2 Under the irradiation of ultraviolet lamp, the reaction is carried out until 2570cm on the infrared spectrum -1 The characteristic peak of the mercapto group disappears; after the reaction, the solvent is evaporated to dryness to obtain an allyl-type macromolecular cross-linking agent.

[0036] The molecular weight and distribution of the macromolecular crosslinking agent prepared in this example were measured by gel permeation chromatography, and the number average molecular weight was measured to be 3800, and the molecular weight distribution was 2.1. It can be seen that the molecular weight of the macromolecular crosslinking agent prepared in this example is much larger than that of the small molecular crossl...

Embodiment 3

[0042] Under the condition of nitrogen atmosphere and ice-water bath, 30g triethylene glycol bis(2-mercaptoacetate) and 33.5g pentaerythritol triallyl ether were respectively dissolved in 95g xylene, mixed and stirred evenly and added 0.51 g benzoyl peroxide, slowly heated to 70 ° C to react until 2570 cm on the infrared spectrum -1 The characteristic peak of the mercapto group disappears; after the reaction, the solvent is evaporated to dryness to obtain an allyl-type macromolecular cross-linking agent.

[0043] The molecular weight and distribution of the macromolecular crosslinking agent prepared in this example were measured by gel permeation chromatography, and the number average molecular weight was measured to be 7300, and the molecular weight distribution was 1.9. It can be seen that the molecular weight of the macromolecular crosslinking agent prepared in this example is much larger than that of the small molecular crosslinking agent pentaerythritol triallyl ether (it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com