Graphite-base carbon dioxide adsorbent and preparation method thereof

A carbon dioxide and graphite-based technology, applied in chemical instruments and methods, through adsorption, separation methods, etc., can solve the problems of easy volatilization or degradation of amines, decreased absorption capacity, poor stability, etc., and achieve easy desorption process and equipment corrosion The effect of small and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

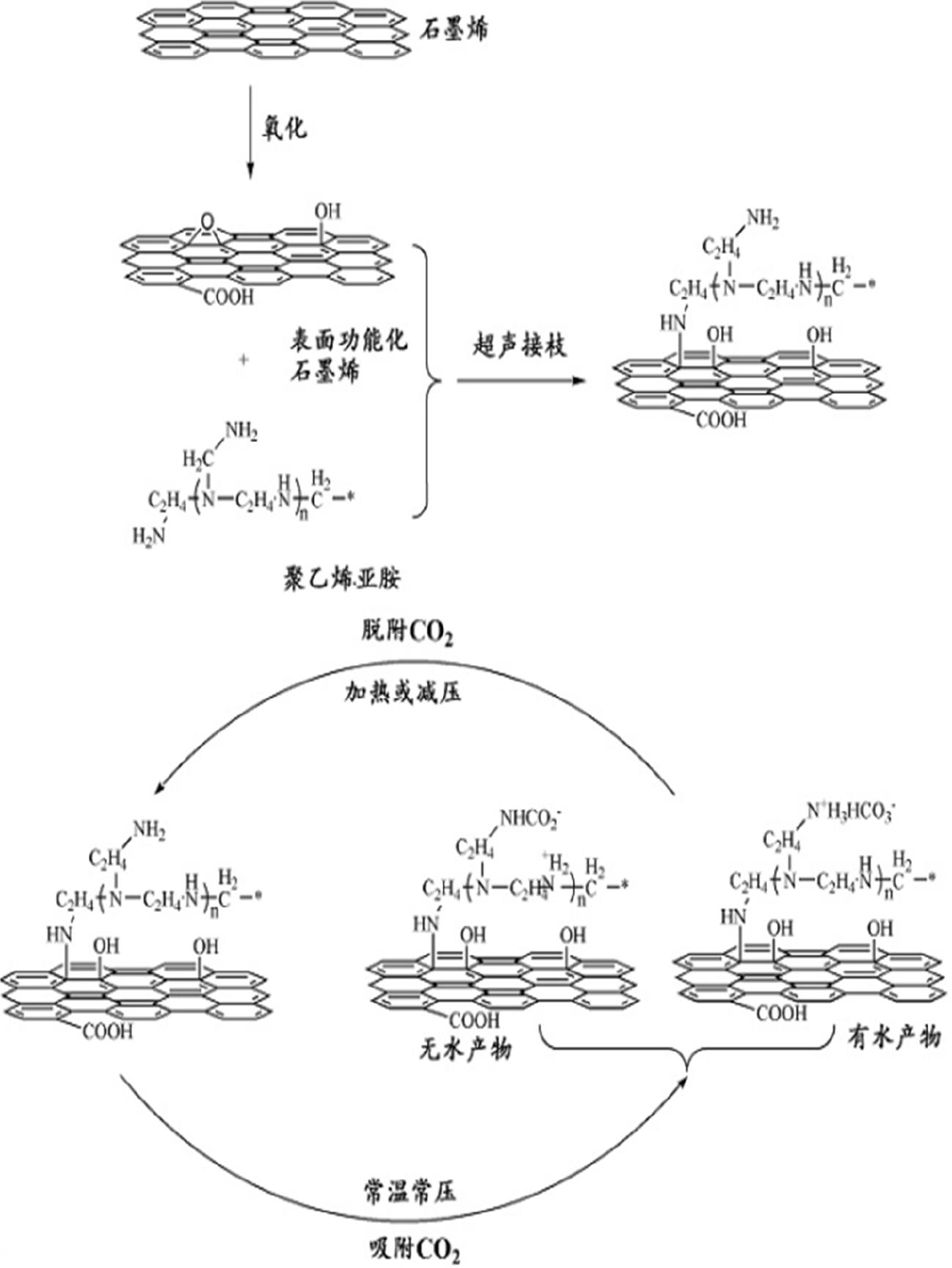

Method used

Image

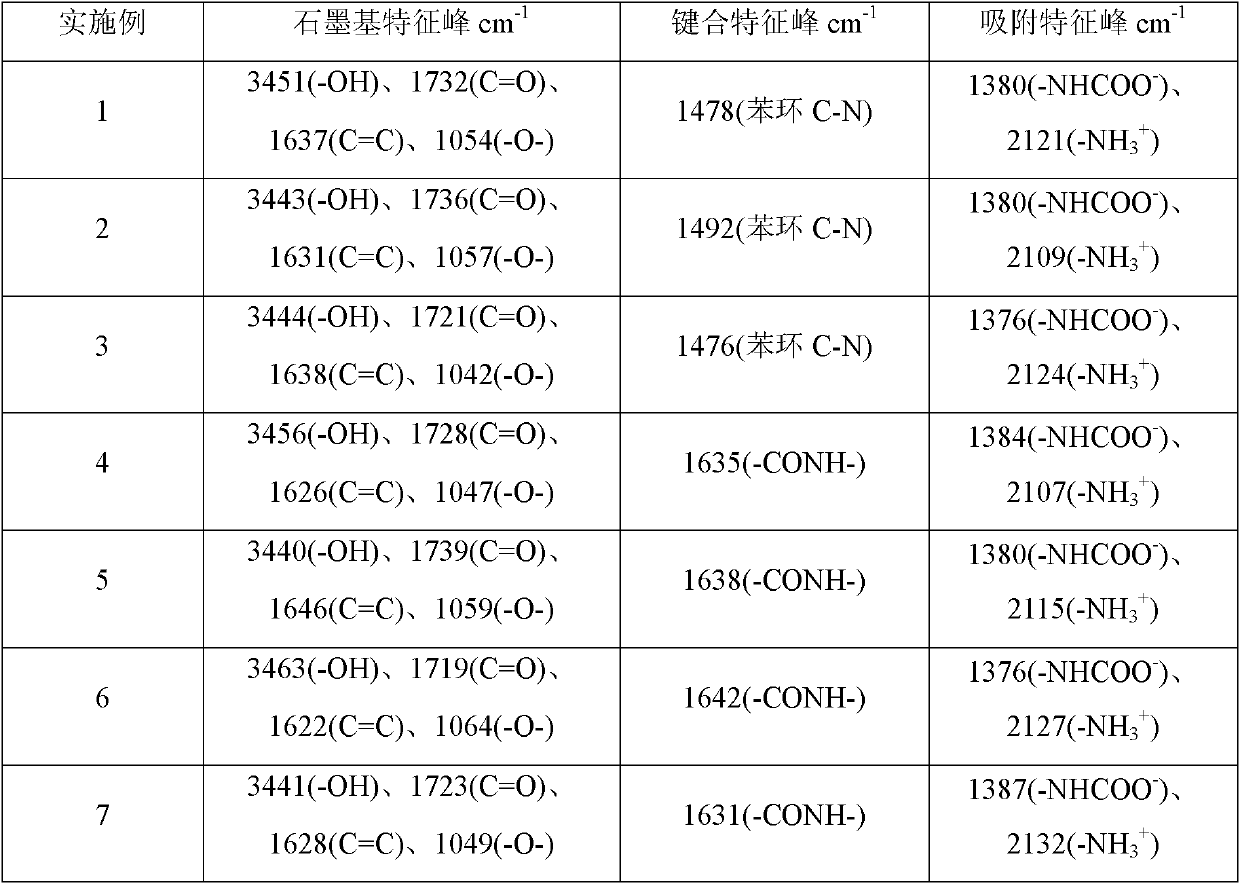

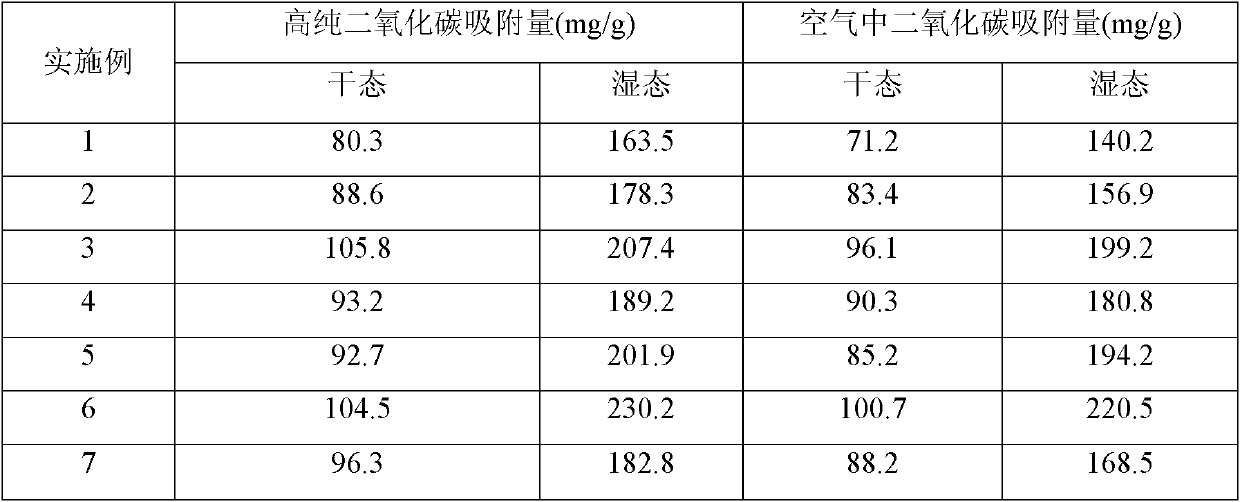

Examples

Embodiment 1

[0027] Add 10g of graphite flakes and 100g of concentrated nitric acid into a clean and dry three-necked bottle, then raise the temperature to 100°C for 1 hour, cool to room temperature after the reaction and dilute the excess oxidant with distilled water, filter, wash and dry to obtain surface functionalization flake graphite.

[0028] Take 5 g of the above-mentioned surface-functionalized graphite flakes and disperse them in 50 g of water, add 0.5 g of polyallylamine (weight average molecular weight: 500), and react ultrasonically for 48 hours at 30° C., cool to room temperature after the reaction, filter, wash, and After drying, the flake graphite carbon dioxide adsorbent can be obtained.

[0029] Add 2.5 g of water to the dry flake graphite carbon dioxide adsorbent to obtain a wet flake graphite carbon dioxide adsorbent.

Embodiment 2

[0031] Add a mixture of 10g of expanded graphite, 1000g of concentrated nitric acid and concentrated sulfuric acid (mass ratio of 1:1) into a clean and dry three-necked flask, then heat up to 30°C for 48 hours, cool to room temperature after the reaction and dilute the excess oxidant with distilled water , filtered, washed and dried to obtain surface-functionalized expanded graphite.

[0032] Take 5g of the above-mentioned surface-functionalized expanded graphite and disperse it in 50g of water, add 10g of tetraethylenepentamine, and conduct ultrasonic reaction for 20 hours at 80°C. After the reaction, cool to room temperature, filter, wash and dry to obtain expanded graphite carbon dioxide adsorbent.

[0033] Add 10 g of water to the dry expanded graphite carbon dioxide adsorbent to obtain a wet state expanded graphite carbon dioxide adsorbent.

Embodiment 3

[0035] Add 10g of carbon nanotubes and 200g of concentrated nitric acid into a clean and dry three-necked bottle, then raise the temperature to 60°C and react for 36 hours. After the reaction, cool to room temperature and dilute the excess oxidant with distilled water, filter the diluted solution, wash and dry. Obtain surface functionalized carbon nanotubes.

[0036] Disperse 5 g of the surface-functionalized carbon nanotubes in 200 g of water, add 5 g of triethylenetetramine, and conduct ultrasonic treatment for 48 hours at 80 ° C. After the reaction, cool to room temperature, filter, wash, and dry to obtain carbon nanotubes. Nanotube carbon dioxide adsorbent.

[0037] Add 4 g of water to the above dry carbon nanotube carbon dioxide adsorbent to obtain a wet carbon nanotube carbon dioxide adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com