Method for preparing modified basalt fiber/polyphenylene sulfide compound filter material through dip coating

A technology of basalt fiber and polyphenylene sulfide, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of high spinning temperature of polyphenylene sulfide, poor fluidity, deep color of products, etc., and achieve improvement Filtration performance and mechanical properties, strong mechanical strength, smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

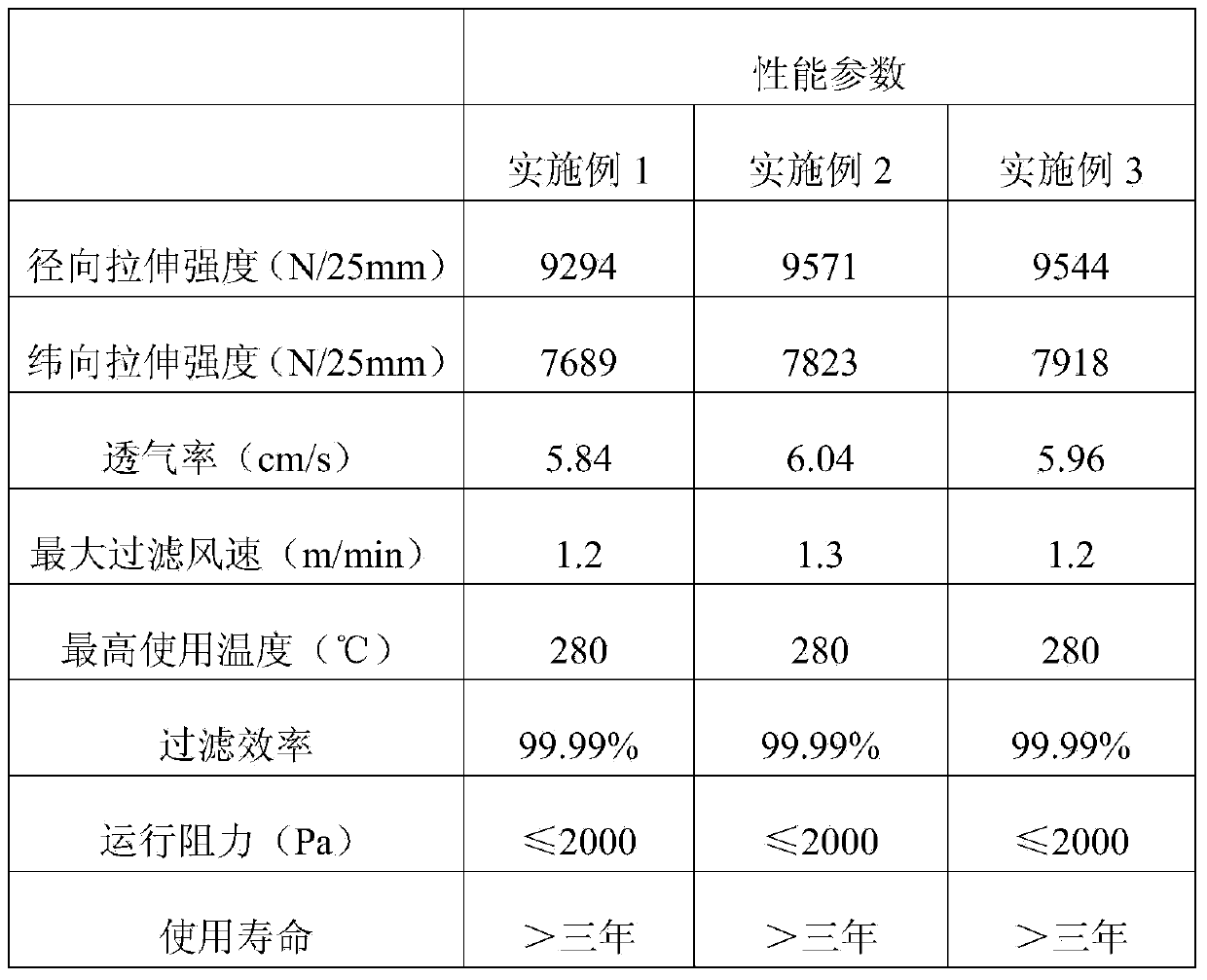

Embodiment 1

[0022] Preparation of hyperbranched polyphenylene sulfide: Add 10g of 3,4-dichlorothiophenol, 13.4g of anhydrous potassium carbonate and 80mL of N-methylpyrrolidone into a 250mL three-necked flask, heat to 150°C, and keep warm for 8.5h. The product was washed and filtered with hydrochloric acid, dissolved in tetrahydrofuran, extracted with hexane, filtered and dried to obtain light brown hyperbranched PPS powder with a degree of polymerization of 8-12.

[0023] Preparation of modified polyphenylene sulfide fibers: respectively place linear polyphenylene sulfide slices and hyperbranched polyphenylene sulfide powder in a drying oven at 130°C for 6 hours, mix them at a weight ratio of 4:1, and put the raw materials into a micro The twin-screw extruder is blended and sent out for winding, and the spinning temperature is 320°C.

[0024] Preparation of modified basalt fiber / polyphenylene sulfide composite filter base cloth: open and mix the modified polyphenylene sulfide fiber and b...

Embodiment 2

[0027] Preparation of hyperbranched polyphenylene sulfide: Add 10g of 3,4-dichlorothiophenol, 13.4g of anhydrous potassium carbonate and 80mL of N-methylpyrrolidone into a 250mL three-necked flask, heat to 150°C, and keep warm for 8.5h. The product was washed and filtered with hydrochloric acid, dissolved in tetrahydrofuran, extracted with hexane, filtered and dried to obtain light brown hyperbranched PPS powder with a degree of polymerization of 8-12.

[0028] Preparation of modified polyphenylene sulfide fibers: respectively place linear polyphenylene sulfide slices and hyperbranched polyphenylene sulfide powder in a drying oven at 130°C for 6 hours, mix them at a weight ratio of 9:1, and put the raw materials into a micro The twin-screw extruder is blended and sent out for winding, and the spinning temperature is 320°C.

[0029] Prepare modified basalt fiber / polyphenylene sulfide composite filter base cloth: open and mix modified polyphenylene sulfide fiber and basalt fiber...

Embodiment 3

[0032] Preparation of hyperbranched polyphenylene sulfide: Add 10g of 3,4-dichlorothiophenol, 13.4g of anhydrous potassium carbonate and 80mL of N-methylpyrrolidone into a 250mL three-necked flask, heat to 150°C, and keep warm for 8.5h. The product was washed and filtered with hydrochloric acid, dissolved in tetrahydrofuran, extracted with hexane, filtered and dried to obtain light brown hyperbranched PPS powder with a degree of polymerization of 8-12.

[0033] Preparation of modified polyphenylene sulfide fibers: respectively place linear polyphenylene sulfide slices and hyperbranched polyphenylene sulfide powder in a drying oven at 130°C for 6 hours, mix them at a weight ratio of 5:1, and put the raw materials into a micro The twin-screw extruder is blended and sent out for winding, and the spinning temperature is 320°C.

[0034] Prepare modified basalt fiber / polyphenylene sulfide composite filter material base cloth: open and mix the modified polyphenylene sulfide fiber and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com