Solid lipid nanoparticle or liposome and preparation method thereof

A solid lipid nano and liposome technology, which is applied in liposome delivery, inorganic non-active ingredients, powder delivery, etc., can solve the problems of drug leakage, low process scale level, high solubility, etc., and achieve improved product stability , The effect of low equipment requirements and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

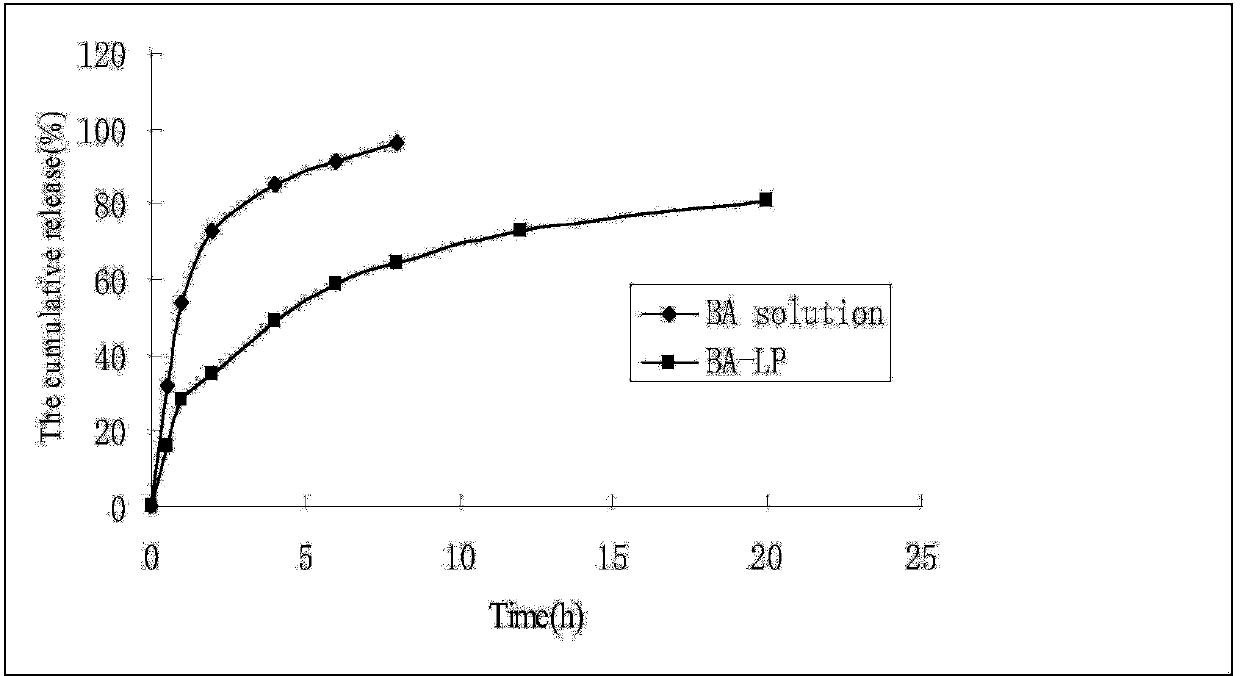

Image

Examples

Embodiment 1

[0068] The preparation of embodiment 1 liposome

[0069] Formula ratio

[0070] Baicalin: 96mg

[0071] Tween 80: 50mg

[0072] Citric acid: 50

[0073] Hydrogenated soy lecithin: 96mg

[0074] Sodium bicarbonate: 25mg

[0075] Mannitol: 250mg

[0076] The detailed steps of the preparation process are as follows:

[0077] (1) Weigh baicalin, Tween 80, citric acid, and hydrogenated soybean lecithin according to the provided formula, dissolve them in ethanol, and perform sterile filtration to obtain solution I;

[0078] (2) Take sodium bicarbonate and mannitol according to the formula provided, dissolve them in water, and perform sterile filtration to obtain solution II;

[0079] (3) Under the condition of high-speed stirring of the solution II, add the solution I to it, and mechanically stir within 80° C. to evaporate the organic solvent to obtain the drug particle suspension III (solution state preparation).

[0080] Alternatively, the drug microparticle suspension III...

Embodiment 2

[0082] The preparation of embodiment 2 liposome

[0083] Formula ratio

[0084] Baicalin: 96mg

[0085] Tween 80: 50mg

[0086] Citric acid: 50mg

[0087] Hydrogenated soy lecithin: 96mg

[0088] Sodium bicarbonate: 25mg

[0089] Mannitol: 250mg

[0090] The detailed steps of the preparation process are as follows:

[0091] (1) Weigh baicalin, Tween 80, citric acid, and hydrogenated soybean lecithin according to the provided formula, dissolve them in ethanol, and perform sterile filtration to obtain solution I;

[0092] (2) Take sodium bicarbonate and mannitol according to the formula provided, dissolve them in water, and perform sterile filtration to obtain solution II;

[0093] (3) Under the condition of high-speed stirring of solution II, solution I was added thereto, and the organic solvent was removed by rotary evaporation within 80° C. to obtain drug particle suspension III (solution state preparation).

[0094] Alternatively, the drug microparticle suspension II...

Embodiment 3

[0096] The preparation of embodiment 3 liposome

[0097] Formula ratio

[0098] Baicalin: 96mg

[0099] Citric acid: 50mg

[0100] Hydrogenated soy lecithin: 96mg

[0101] Sodium bicarbonate: 25mg

[0102] Mannitol: 250mg

[0103] The detailed steps of the preparation process are as follows:

[0104] (1) Weigh baicalin, citric acid, and hydrogenated soybean lecithin according to the provided formula, dissolve them in ethanol, and perform sterile filtration to obtain solution I;

[0105] (2) Take sodium bicarbonate and mannitol according to the formula provided, dissolve them in water, and perform sterile filtration to obtain solution II;

[0106] (3) Under the condition of high-speed stirring of solution II, solution I was added thereto, and the organic solvent was removed by rotary evaporation within 80° C. to obtain drug particle suspension III (solution state preparation).

[0107] Alternatively, the drug microparticle suspension III is dried under reduced pressure a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com