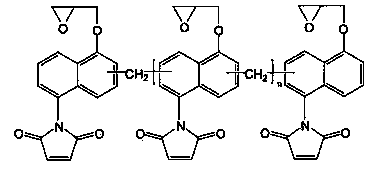

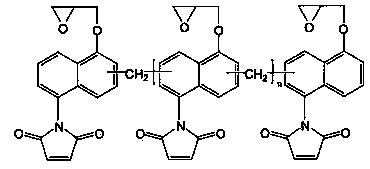

Dual-network crosslinked epoxy resin and preparation method thereof

A technology of epoxy resin and double network, applied in the field of epoxy resin, can solve problems such as limiting heat resistance, and achieve the effects of increasing crosslinking density, high thermal decomposition temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

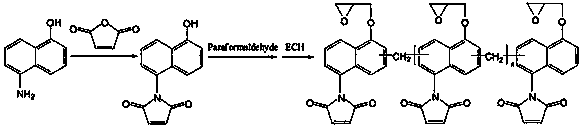

Method used

Image

Examples

Embodiment 1

[0025] Add 320 g of 5-amino-1-naphthol and 200 g of xylene into a 1000 mL four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a nitrogen introduction device, slowly raise the temperature of the oil bath to 125 ° C, and wait for 5- After amino-1-naphthol was completely dissolved, 240 g of maleimide was dissolved in 280 g of xylene, and slowly added dropwise to the reaction system. After 2 hours of addition, the reaction temperature was controlled at 125° C., and the reaction was continued for 6 hours. After completion of the reaction, cool down and distill off the solvent and excess water under reduced pressure to obtain a yellow semi-solid product. Add 140 g of the obtained yellow semi-solid product and 200 g of methyl isobutyl ketone into a 500 ml four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a nitrogen introduction device, react at 120 ° C for 8 h, cool and distill under reduced pressure to ...

Embodiment 2

[0029] Add 45 g of 5-amino-1-naphthol and 80 g of xylene into a 250 mL four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser, and a nitrogen introduction device, and slowly raise the temperature of the oil bath to 115° C., and wait for 5- After amino-1-naphthol was completely dissolved, 35 g of maleimide was dissolved in 80 g of xylene, and slowly added dropwise to the reaction system. After 2 hours of addition, the reaction temperature was controlled at 115° C., and the reaction was continued for 3 hours. After the reaction was completed, it was cooled and the solvent and excess water were distilled off under reduced pressure to obtain a yellow viscous product. Add 14 g of the obtained yellow viscous product and 20 g of methyl isobutyl ketone into a 100 ml four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a nitrogen introduction device, react at 120 ° C for 8 h, cool and distill under reduced pressure ...

Embodiment 3

[0033] Add 4500 g of 5-amino-1-naphthol and 8000 g of xylene in the 25L enamel reactor equipped with electric heating oil bath jacket, mechanical stirring, thermometer, reflux condenser and nitrogen gas introduction device, slowly raise the oil bath temperature to 125°C, after 5-amino-1-naphthol is completely dissolved, dissolve 3800 g of maleimide in 8000 g of xylene, and slowly add it dropwise to the reaction system. After 2 hours of feeding, the reaction temperature is controlled at 125°C, continue Reaction 2h. After the reaction was completed, it was cooled and the solvent and excess water were distilled off under reduced pressure to obtain a yellow viscous product. Add 1,400 g of the obtained yellow viscous product and 2,000 g of methyl isobutyl ketone into a 10 L enamel reactor equipped with an electric heating oil bath jacket, mechanical stirring, thermometer, reflux condenser, and nitrogen introduction device, and react at 120°C for 6 hours, then cool The solvent and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com