A kind of epoxy resin containing furan self-repairing group and preparation method thereof

An epoxy resin, self-repairing technology, applied in the direction of organic chemistry, etc., to achieve the effect of inhibiting chain segment movement and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

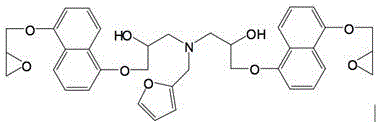

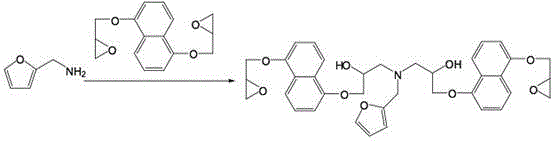

Image

Examples

Embodiment Construction

[0020] Add 8 g of 1,5-naphthalenediol, 46.2 g of epichlorohydrin and 23.1 g of isopropanol in a 125 mL four-neck flask equipped with mechanical stirring, a thermometer, a reflux condenser, a numerically controlled sampling pump, and a nitrogen introduction device, Slowly raise the temperature of the oil bath to 60°C. After the 1,5-naphthalenediol is completely dissolved, slowly add 16 g of NaOH solution (30wt%) with a numerical control injection pump. The injection is completed within 2 hours, and the reaction temperature is controlled at Continue to react at 80°C for 4 hours. After the reaction is completed, cool and filter to remove the generated sodium chloride, distill under reduced pressure to remove the solvent, dissolve it in toluene again, wash with deionized water for 3 times, and recrystallize with dichloromethane after removing the solvent to obtain Pale yellow solid product. . Dissolve 10 g of the above-mentioned light yellow solid product in 60 g of xylene and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com