Self-healing functional epoxy resin containing biphenyl structure and preparation method of self-healing functional epoxy resin

A technology of epoxy resin and biphenyl structure, which is applied in the field of self-healing functional epoxy resin and its preparation, can solve the problem of limited toughness of resin cured product, and achieve the effect of inhibiting chain segment movement and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

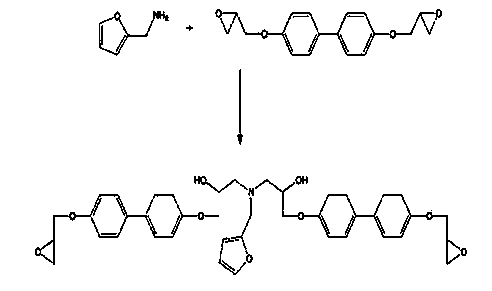

Method used

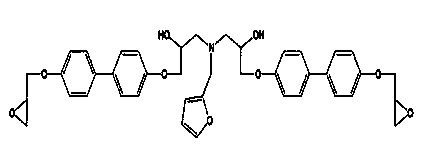

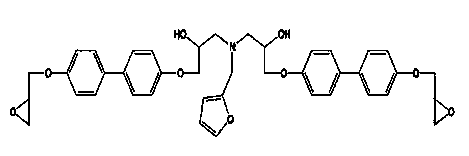

Image

Examples

Embodiment 1

[0020] Add 10.5 g of 4,4'-diphenol, 46 g of epichlorohydrin and 18.5 g of n-butanol into a 125 mL four-necked flask equipped with mechanical stirring, thermometer, reflux condenser, digitally controlled sampling pump and nitrogen introduction device , slowly increase the temperature of the oil bath to 60°C, and after the 4,4'-biphenol is completely dissolved, slowly add 16 g of NaOH solution (30wt%) with a numerical control injection pump, and the injection is completed within 1 hour, and the reaction The temperature was controlled at 60°C, and the reaction was continued for 3 hours. After the reaction was completed, the sodium chloride formed was removed by cooling and filtration, the solvent was removed by distillation under reduced pressure, dissolved in toluene again, and washed with deionized water for 3 times. Recrystallization gave the product as a white solid. Dissolve 20 g of the above-mentioned white solid product in 60 g of xylene and place it in a 125 mL four-necke...

Embodiment 2

[0022] Add 12 g of 4,4'-diphenol, 47 g of epichlorohydrin and 20 g of n-butanol into a 125 mL four-necked flask equipped with mechanical stirring, a thermometer, a reflux condenser, a numerically controlled sampling pump, and a nitrogen introduction device, Slowly increase the temperature of the oil bath to 55°C. After the 4,4'-biphenol is completely dissolved, slowly add 14 g of NaOH solution (30wt%) with a numerically controlled injection pump. The injection is completed within 1 hour. The reaction temperature Control the temperature at 60°C and continue the reaction for 4 hours. After the reaction is completed, cool and filter to remove the generated sodium chloride, distill under reduced pressure to remove the solvent, dissolve it again with toluene, wash with deionized water for 3 times, remove the solvent, and reapply with dichloromethane. Crystallization gave the product as a white solid. Dissolve 18 g of the above-mentioned white solid product in 62 g of xylene and pla...

Embodiment 3

[0024] The 100g self-healing functional epoxy resin containing biphenyl structure prepared by the above two examples is mixed with 21.2 g DDS and 5.1 g BDM, dissolved in 250 ml acetone and 250 ml N,N-dimethylformamide mixed solvent, After the dissolution was completed, the solvent was distilled off under reduced pressure to obtain a mixture of resin and curing agent 126g, cured at 120°C for 1h, 180°C for 1h, and 220°C for 2h to obtain a cured resin with a glass transition temperature of 207°C (DMA method), using the scratch method , after the material was heated at 180℃ for 6h, the repair size efficiency was 81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com