Preparation method of lithium-ion type perfluorosulfonic acid resin coated aluminum-lithium alloy material

A technology of perfluorosulfonic acid resin and aluminum coating, applied in the field of lithium-ion batteries, can solve the problems of irreversible capacity loss, electrode failure, loss of reversible lithium storage effect, etc., achieve good chemical stability and thermal stability, and smooth charging The effect of discharge voltage platform and good electrode reaction reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

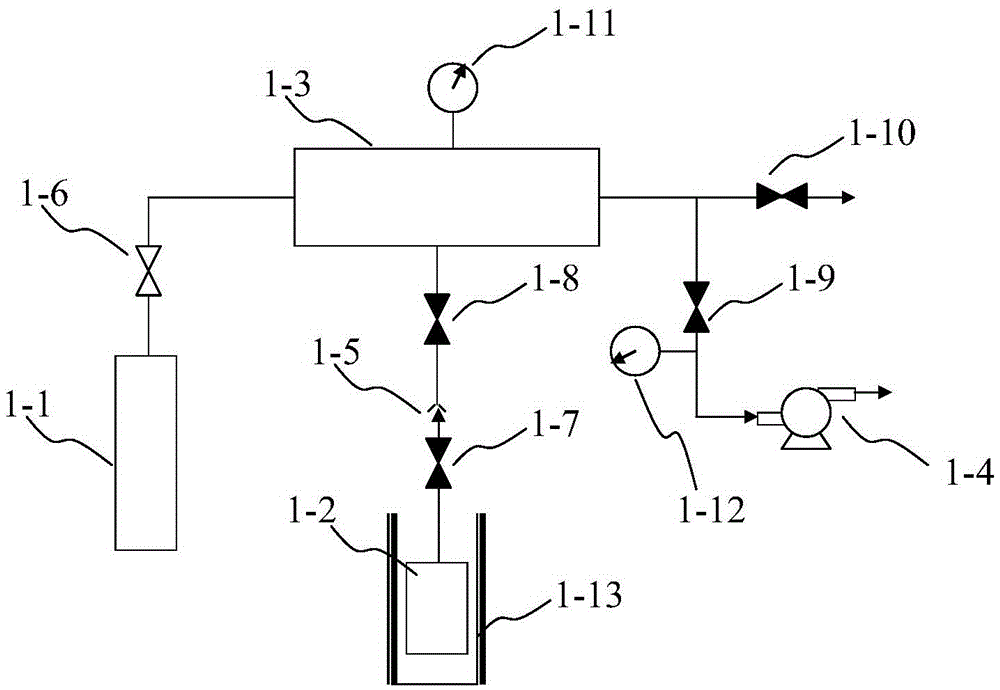

[0044] A method for preparing an aluminum-lithium alloy material coated with a Li-ion type perfluorosulfonic acid resin. The Li-ion type perfluorosulfonic acid resin-coated aluminum-lithium alloy material is used as a negative electrode material for a lithium battery. The preparation method specifically includes the following steps :

[0045] (1) In an argon atmosphere glove box with water content and oxygen content less than 1ppm, take aluminum powder and lithium sheet and put them in 316 stainless steel reactor 1-2, seal the reactor 1-2 and remove from the glove box , connected to the hydrogenation unit; wherein, the mass ratio of aluminum powder and lithium flakes is 27:7;

[0046] (2) Vacuum the reactor 1-2, and the vacuum degree reaches 10 2 After Pascal, raise the temperature of reactor 1-2 to 550°C, and react for 2 hours to generate block lithium aluminum alloy; after the reaction, cool reactor 1-2 to 200°C, and pass Enter high-purity hydrogen (purity: 99.999%) at 40 ...

Embodiment 1 4

[0058] Example 1 Preparation of Lithium Aluminum Hydride

[0059] In a glove box protected by an argon atmosphere (both water content and oxygen content are less than 1ppm), take 27g of aluminum powder and 7g of lithium sheet and place them in a reactor made of 316 stainless steel. After sealing the reactor, remove it from the glove box and pass it through the pipe joint 1 -5 connected to hydrogenation unit, such as figure 1 As shown in , all valves of the hydrogenation unit are initially closed. Open the shut-off valves 1-7, 1-8, 1-9, and vacuum until the vacuum gauge 1-12 shows 10 2 Close the stop valves 1-9 after Pascal. The electric heating furnace 1-13 is heated up to 550°C, and after the reactor temperature rises to 550°C for 2 hours, it is cooled to 200°C; the pressure reducing valve 1-6 is opened to make the high-purity hydrogen in the high-purity high-pressure hydrogen bottle 1-1 ( Purity: 99.999%) is charged into hydrogen storehouse 1-3, makes the pressure of hydr...

Embodiment 2

[0060] Example 2 Preparation of Lithium Aluminum Hydride Tetrahydrofuran Solution

[0061] In a glove box protected by an argon atmosphere (water content and oxygen content are both less than 1ppm), take 2.7g of aluminum powder and 0.7g of lithium sheet into a 316 stainless steel reactor, seal the reactor, remove it from the glove box, and connect it through a pipe Devices 1-5 are connected to the hydrogenation unit, such as figure 1 As shown, all valves of the hydrogenation unit are initially closed. Open the stop valves 1-7, 1-8, 1-9, and vacuum until the vacuum gauge 1-12 shows 10 2 Close the stop valves 1-9 after Pascal. The electric heating furnace 1-13 is heated up to 550°C, and after the reactor temperature rises to 550°C for 2 hours, it is cooled to 200°C; the pressure reducing valve 1-6 is opened to make the high-purity hydrogen in the high-purity high-pressure hydrogen bottle 1-1 ( Purity: 99.999%) is charged into hydrogen storehouse 1-3, makes the pressure of hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com