An ecological restoration type prefabricated concrete slab and a method for reconstructing hard bank revetment and river bed restoration

A technology of prefabricated concrete slabs and ecological restoration, which is applied in the direction of coastline protection, water resources protection, silicates, etc., can solve the problems of ecosystem damage and biodiversity reduction, and achieve good workability, strong adsorption capacity, and suitable The effect of plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The mass composition per cubic meter of lightweight permeable concrete is:

[0050] Silt-based ceramsite: 470kg / m 3 ;

[0051] Sulphoaluminate cement: 230kg / m 3 ;

[0052] Granular restoration agent: 40kg / m 3 ;

[0053] Efficient additive: 3.5kg / m 3 ;

[0054] Water: 90kg / m 3 ,

[0055] Among them, the particle size of silt-based ceramsite is 10-20mm, and its performance parameters are shown in Table 1; the cement is sulphoaluminate cement; the mass percentage of high-efficiency additives is 45% polycarboxylate high-performance water-reducing 40% triisopropanolamine strengthening component and 15% EVA emulsion thickening component; the repairing agent is composed of 60% zeolite particles and 40% expanded perlite particles by volume fraction (in the stacked state) .

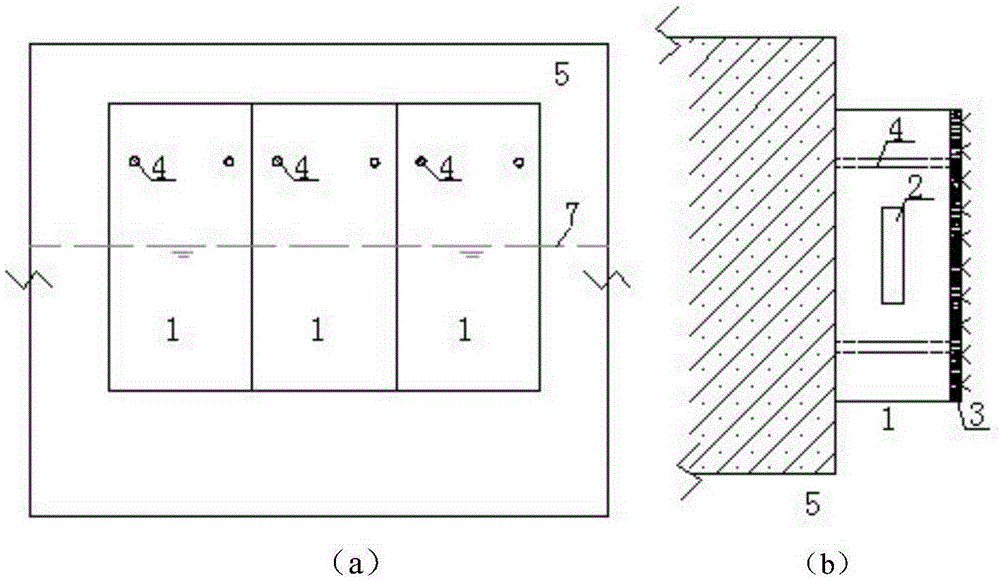

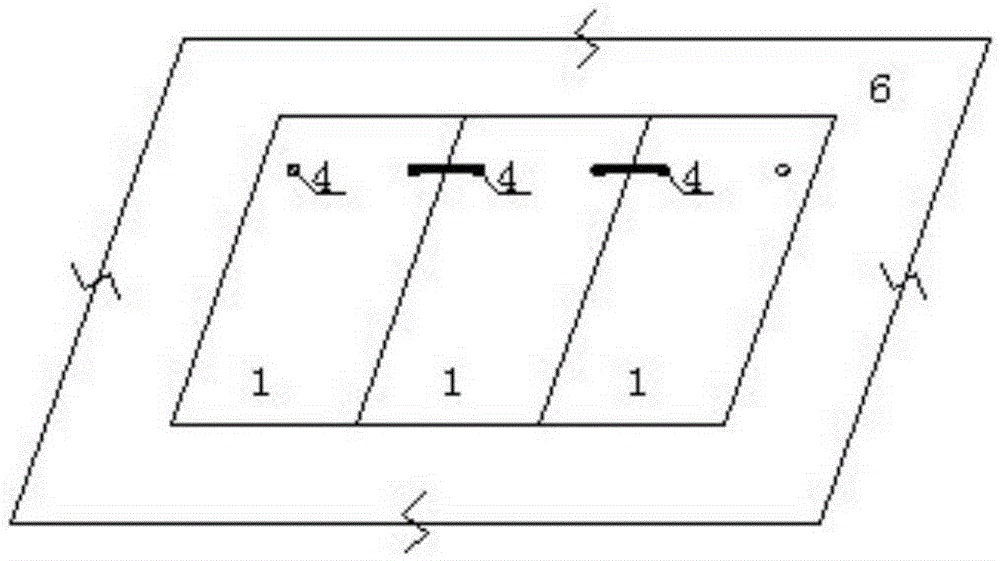

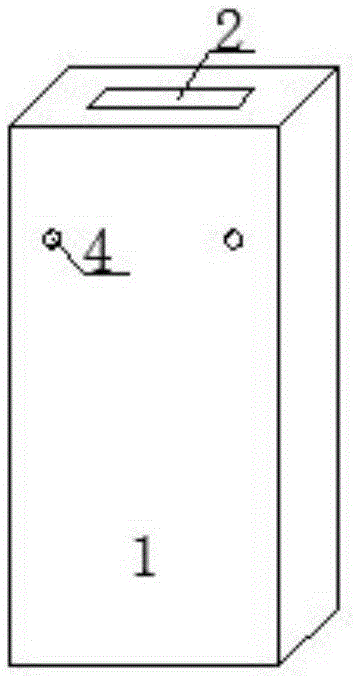

[0056] Prefabricated concrete slab mold: the internal size of the mold is 60cm×30cm×12cm, there is a 60cm×10cm×3cm rectangular formwork in the middle of the mold to reserve the slot 2 for placing ...

Embodiment 2

[0062] The mass composition per cubic meter of lightweight permeable concrete is:

[0063] Silt ceramsite: 440kg / m 3 ;

[0064] Sulphoaluminate cement: 200kg / m 3 ;

[0065] Granular restoration agent: 60kg / m 3 ;

[0066] Efficient additive: 7kg / m 3 ;

[0067] Water: 50kg / m 3 ,

[0068] Among them, the silt ceramsite is formed by compounding two kinds of ceramsite with different particle sizes in Table 1 according to 1:1; the cement is sulphoaluminate cement; Water-reducing component, 20% triisopropanolamine reinforcing component and 10% EVA emulsion thickening component; the repairing agent is composed of 65% zeolite particles and 35% expanded perlite particles.

[0069] Prefabricated concrete slab mold: the internal size of the mold is 60cm×30cm×12cm, there is a 60cm×10cm×3cm rectangular formwork in the middle of the mold to reserve the slot 2 for placing the filler plate, and the 2cm on both sides of the formwork are PVC pipe sockets for prefabricated Leave the ins...

Embodiment 3

[0073] The mass composition per cubic meter of lightweight permeable concrete is:

[0074] Silt ceramsite: 470kg / m 3 ;

[0075] Sulphoaluminate cement: 250kg / m 3 ;

[0076] Granular restoration agent: 60kg / m 3 ;

[0077] Efficient additive: 5.5kg / m 3 ;

[0078] Water: 70kg / m 3 ,

[0079] Among them, the particle size of silt ceramsite is 20-25mm, and its properties are shown in Table 1; the cement is sulphoaluminate cement; % triisopropanolamine reinforcing component and 20% EVA emulsion thickening component; the repairing agent is composed of 70% zeolite particles and 30% expanded perlite particles.

[0080]Prefabricated concrete slab mold: the internal size of the mold is 60cm×30cm×12cm, there is a 60cm×10cm×3cm rectangular formwork in the middle of the mold to reserve the slot 2 for placing the filler plate, and the 2cm on both sides of the formwork are PVC pipe sockets for prefabricated Leave the installation hole 4, and the socket is 20cm away from one side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com