Single-wall carbon nanohorn-hollow nanogold compound and method for preparing single-wall carbon nanohorn-hollow nanogold compound

A single-walled carbon nanohorn and hollow nanotechnology, applied in the field of nanomaterials, can solve problems such as insufficient combination, affecting the yield and application range of nanocomposites, and achieve good stability, strong physical and chemical adsorption capacity, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

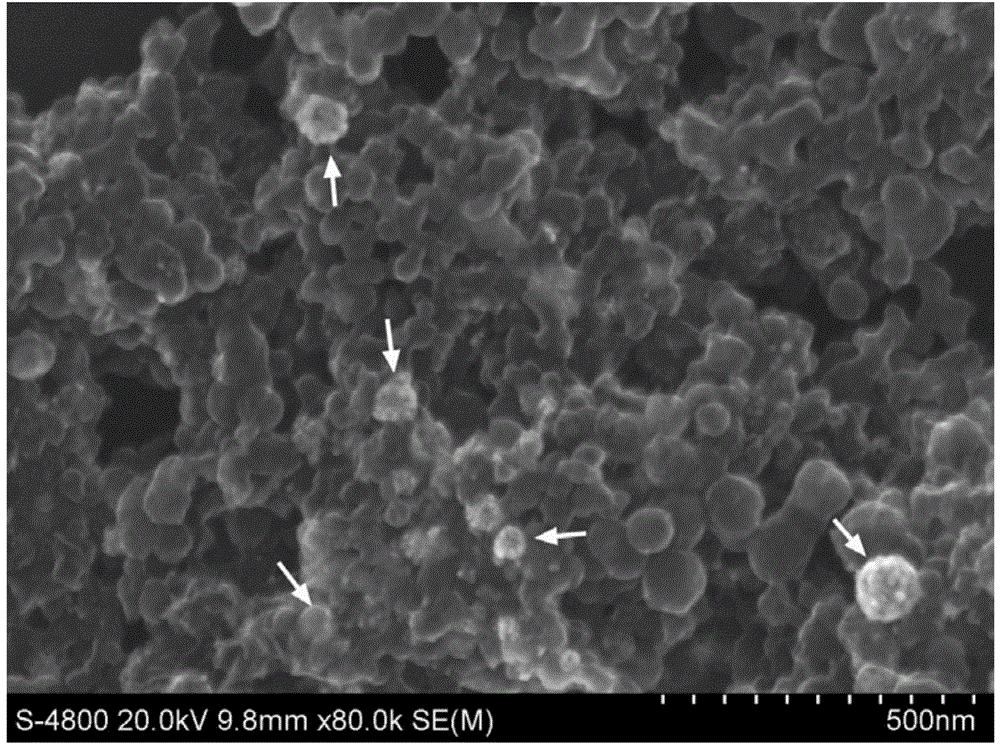

[0033] Experimental example 1. SEM characterization of single-walled carbon nanohorns-hollow gold nanocomposites synthesized by different methods

[0034] Take 3-5 μL each of the single-walled carbon nanohorn-hollow gold nanocomposites prepared in the synthesis examples and comparative synthesis examples, and use SEM to characterize them.

[0035] figure 1 It is the SEM image of the in situ synthesized single-wall carbon nanohorn-hollow gold nanocomposite. As can be seen from the figure, the surface of the compound synthesized in situ in the present invention has a large number of hollow gold nanoparticles with a hollow spherical structure, the diameter ranges from about 30nm to 200nm, and about 75% of the particles have a diameter of about 100nm; about 75%~ 95% of the particles have a weakened middle brightness and stronger surrounding brightness, showing a hollow spherical structure. On the other hand, the distribution of hollow gold nanoparticles on the single-walled carb...

experiment example 2

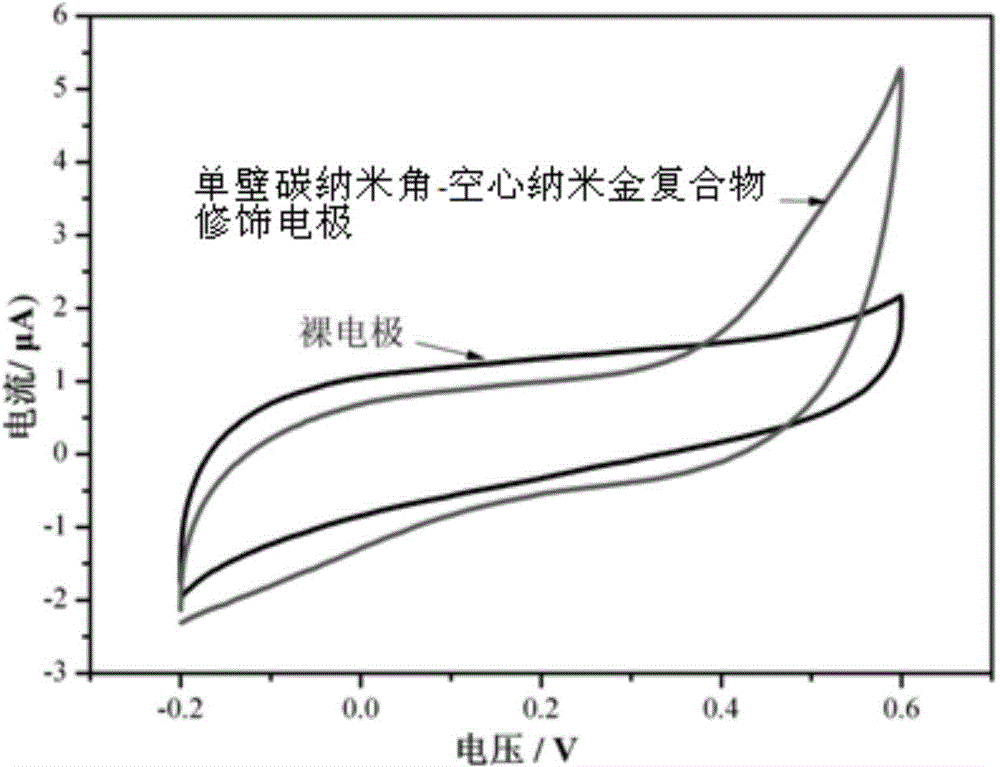

[0038] Experimental example 2. Cyclic voltammetry characterization of in situ synthesized single-walled carbon nanohorns-hollow gold nanocomposites

[0039] Take 10 μL of the single-walled carbon nanohorn-hollow gold nanocomposite synthesized in situ, drop it on a polished bare glassy carbon electrode, dry it at 37°C, put it in 1×PBS (pH7.4), and use cyclic voltammetry characterization. The result is as image 3 As shown, compared with the bare glassy carbon electrode, the electrode current value of the modified in situ synthesized single-walled carbon nanohorn-hollow nanogold composite increased significantly, from 2.167 μA to 5.277 μA, an increase of 2.435 times, indicating that the original The synthesized single-walled carbon nanohorn-hollow gold nanocomposites have excellent electrical conductivity.

experiment example 3

[0040] Experimental example 3. Ultraviolet spectral scanning analysis of in situ synthesized single-walled carbon nanohorns-hollow gold nanocomposites

[0041] Take 10 μL each of the single-walled carbon nanohorn solution, the hollow gold nanohorn solution, and the in-situ synthesized single-walled carbon nanohorn-hollow gold nanocomposite, dilute to 1 mL with deionized water, and perform ultraviolet spectral scanning analysis. The scanning range is 190nm~ 800nm. The result is as Figure 4 As shown, the maximum absorption peak of single-wall carbon nanohorn is located at 267nm, and the absorbance value is 0.401; the maximum absorption peak of hollow gold nanohorn is located at 201nm, and the absorbance value is 0.503; the single-wall carbon nanohorn-hollow gold nanocomposite synthesized in situ There are two maximum absorption peaks, one is located at 201nm, with an absorbance value of 0.465; the other is located near 235nm, with an absorbance value of 0.425; indicating that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com