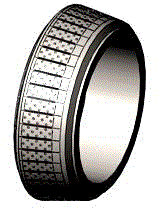

Method for manufacturing TiC hard alloy composite grinding roller

A cemented carbide and composite grinding roller technology, applied in the field of various vertical grinding rollers, can solve problems such as poor wear resistance and fracture, and achieve the effects of wide application range, cost reduction and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a TiC cemented carbide composite grinding roller, characterized in that: comprising the steps of:

[0028] (1) Mix TiC cemented carbide material with a particle size of 60-200 mesh and a binder to obtain a mixture, wherein the mass content of each component is: titanium carbide: 50%, Mn: 7%, Ni: 2%, Mo : 1.5%, Cr: 4%, the balance is iron, binder: 6%;

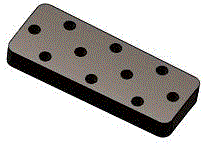

[0029] (2) Fill the above mixture into the mold cavity of the press, the pressure of the press on the mixture is 50MPa, molding and demoulding, and then put the preform into the vacuum furnace with a temperature of 1450°C and a vacuum degree of 0.2-0.4Pa After lower sintering and heat preservation for 180 minutes, the TiC cemented carbide prefabricated parts (such as figure 1 shown);

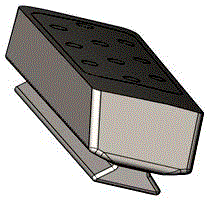

[0030] (3) After sandblasting and preheating the prefabricated parts, fix them on the end face of the casting mold cavity of the liner plate. After closing the mold, pour the iron-based self-fluxing alloy melt ...

Embodiment 2

[0033] A preparation method of a TiC cemented carbide composite grinding roller, characterized in that: comprising the steps of:

[0034] (1) Mix TiC cemented carbide material with a particle size of 60-200 mesh and a binder to obtain a mixture, wherein the mass content of each component is: titanium carbide: 70%, Mn: 5%, Ni: 1%, Mo : 0.6%, Cr: 2%, the balance is iron, binder: 1%;

[0035] (2) Fill the above mixture into the cavity of the press mold, the mixture is subjected to a press pressure of 70MPa, molded and demolded, and then the preform is placed in a vacuum furnace with a temperature of 1350°C and a vacuum degree of 0.2-0.4Pa After lower sintering and heat preservation for 120 minutes, the TiC cemented carbide prefabricated part is obtained after cooling out of the furnace;

[0036] (3) After sandblasting and preheating the prefabricated parts, fix them on the end face of the casting mold cavity of the liner plate. After closing the mold, pour the nickel-based se...

Embodiment 3

[0039] A preparation method of a TiC cemented carbide composite grinding roller, characterized in that: comprising the steps of:

[0040] (1) Mix TiC cemented carbide material with a particle size of 60-200 mesh and a binder to obtain a mixture, wherein the mass content of each component is: titanium carbide: 60%, Mn: 6%, Ni: 1.5%, Mo : 1%, Cr: 3%, the balance is iron, binder: 1%;

[0041] (2) Fill the above-mentioned mixture into the mold cavity of the press, the pressure of the press on the mixture is 60MPa, molding and demoulding, and then put the preform into the vacuum furnace with a temperature of 1150°C and a vacuum degree of 0.2-0.4Pa After lower sintering and heat preservation for 150 minutes, the TiC cemented carbide prefabricated part is obtained by cooling out of the furnace;

[0042] (3) After sandblasting and preheating the prefabricated parts, fix them on the end face of the casting mold cavity of the lining plate. After closing the mold, pour the high chromium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com